Shale thermal insulation material and preparation method thereof

A technology of thermal insulation material and shale rock, applied in the field of building materials, can solve the problems of long maintenance cycle of cement products, high labor intensity of workers and high production cost, and achieve the effects of improving labor conditions, easy operation and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

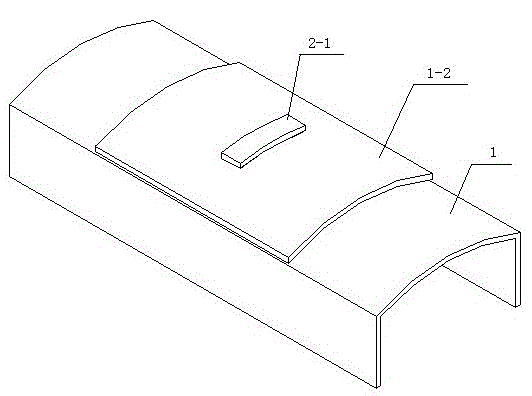

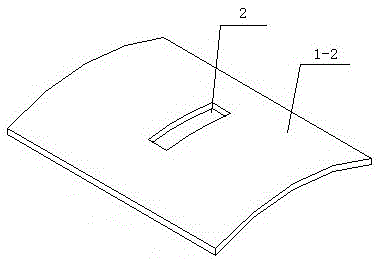

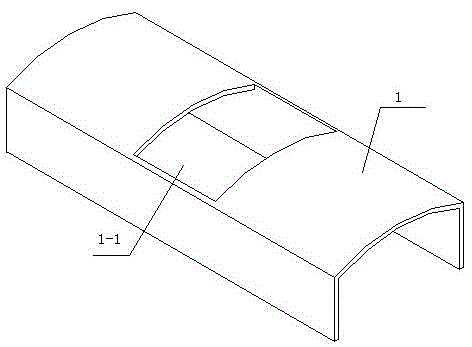

Image

Examples

specific Embodiment approach 1

[0025] Specific Embodiment 1: The shale thermal insulation material of this embodiment is formed by puffing and sintering shale and soda ash as raw materials. The amount of soda ash is determined according to the puffing temperature of the shale. When the temperature is high, its dosage is 5-10% of the shale weight.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the shale thermal insulation material is puffed and sintered from shale and soda ash as raw materials, and the amount of soda ash is 6% of the weight of the shale.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is different from Embodiment 2 in that the amount of soda ash used is 7% of the shale weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com