Inflaming retarding flame-repellent foam core compound light partition wall

A sandwich, light-weight technology, applied in the direction of walls, solid waste management, building components, etc., can solve the problems of easy peeling, easy falling off, weak adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

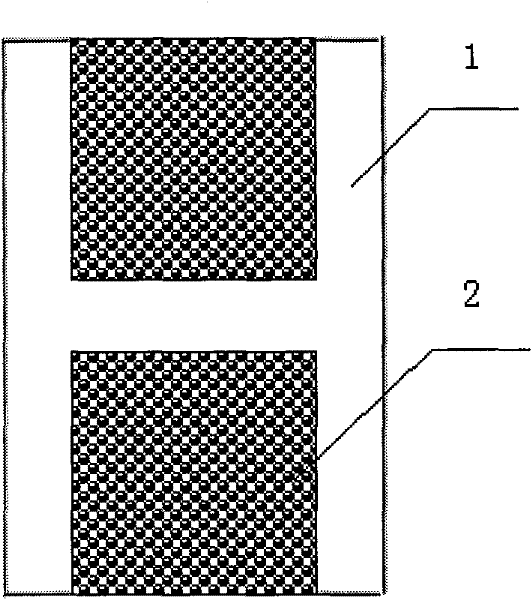

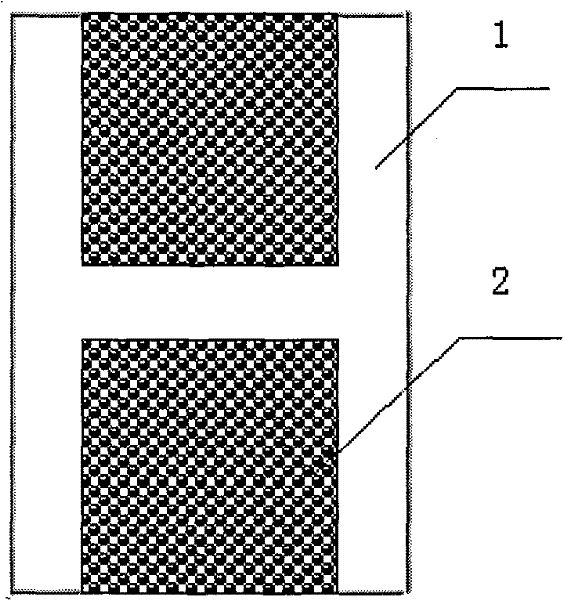

Image

Examples

Embodiment 1

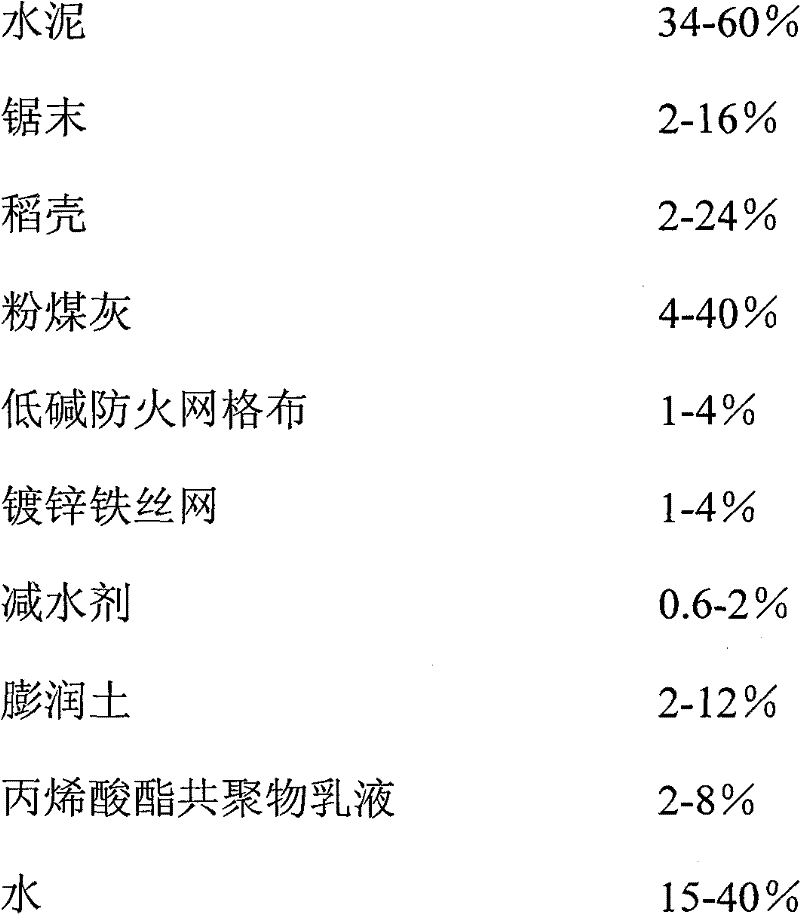

[0023] Taking the 1000mm (length) × 1000mm (width) × 90mm (thickness) flame-retardant and flame-resistant foam sandwich composite lightweight partition wall as an example, the outer wall panel (1) and the inner wall core (2) each The contents of the components are as follows:

[0024] The total weight of the exterior wall panel (1) is 50kg, and the content of each component is

[0025]

[0026]

[0027] The total weight of the inner wall core material is 30kg, wherein the content of each component is

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com