Beer taste drink with high maltol and furaneol contents

A technology of beer flavor and maltol, applied in the field of beer flavor beverage and its manufacture, can solve problems such as not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095]

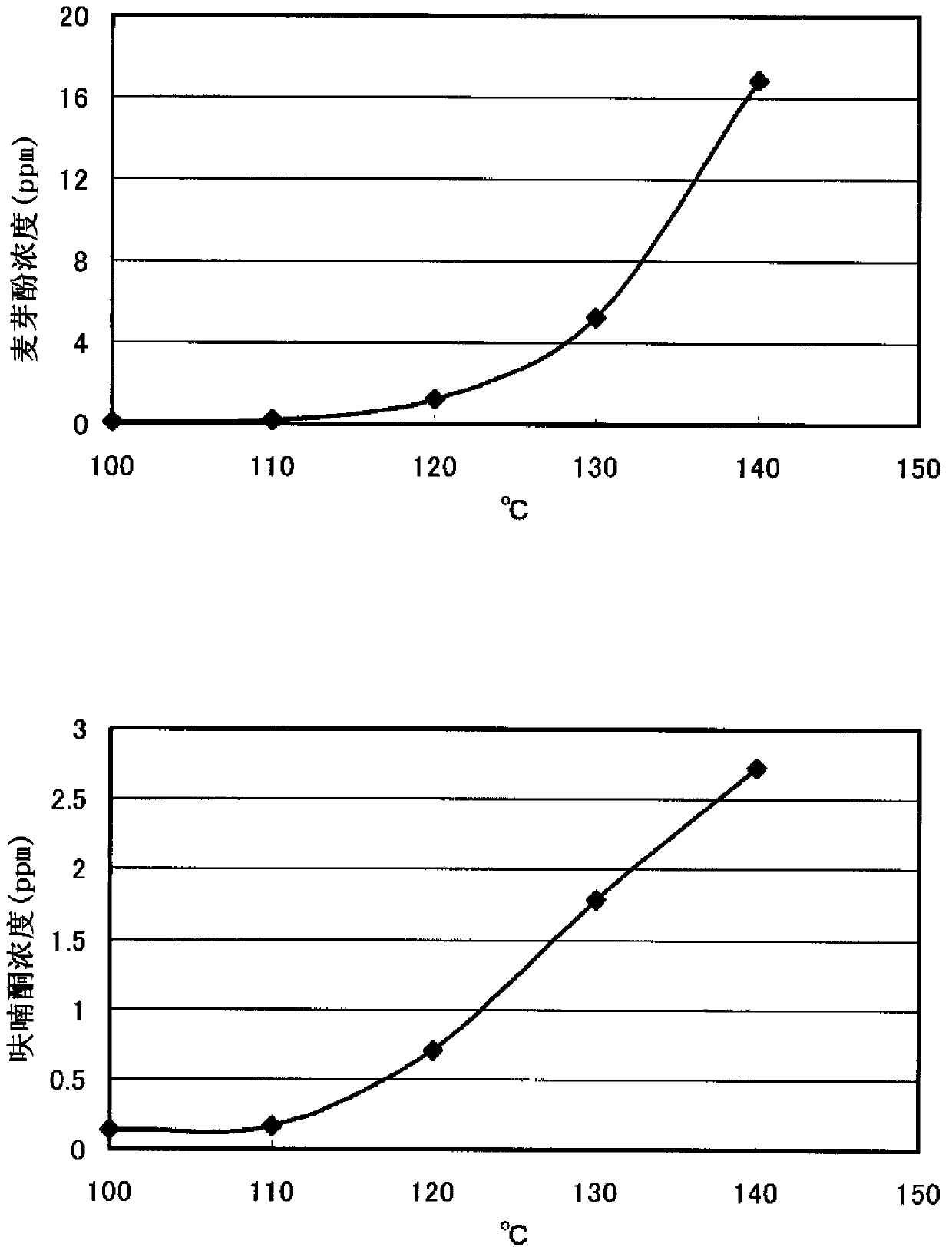

[0096] Wort (fermentation stock solution) was obtained by suspending 3.0 kg of crushed barley malt in 12 L of warm water at 55° C. and maintaining it for 15 minutes. This was heated in an airtight pressure-resistant container, and it was taken out at the time when the temperature became 110 degreeC, 120 degreeC, 130 degreeC, and 140 degreeC, and held for 30 minutes, respectively. The content of maltol and furanone was measured, the chromaticity was measured, and the sensory evaluation was performed about the fermented raw liquid after the heat treatment obtained. The results are shown in Table 1 and figure 1 shown.

[0097] Table 1

[0098]

[0099] It was found that the sensory evaluation was improved in the heat treatment at 120°C to 140°C, and it showed an excellent fragrance especially in the heat treatment at 130°C to 140°C. In addition, by figure 1 It can be seen that the concentration of maltol in the fermentation stock solution starts to increase from...

Embodiment 2

[0105]

[0106] Wort (sample 9) was obtained by suspending 3.0 kg of crushed barley malt in 12 L of 90° C. warm water and maintaining it for 15 minutes. Moreover, the test wort (sample 4 mentioned above) was obtained by suspending 3.0 kg of barley malt in 12 L of 55 degreeC warm water, and maintaining it for 15 minutes. Furthermore, after suspending 3.0 kg of barley malt in 12 L of 55° C. warm water and maintaining it for 15 minutes, the temperature was raised to 65° C. and maintained for 25 minutes to obtain test wort (sample 11). All kinds of wort were heated in a closed pressure-resistant container, and all were processed at 130° C. for 30 minutes. The same evaluation as in Example 1 was performed on the obtained heat-treated sample. The results are shown in Table 3.

[0107] table 3

[0108]

[0109] It can be seen that due to the different pretreatment methods, the contents of maltol and furanone and the fragrance in the fermented stock solution after heat treatme...

Embodiment 3

[0112]

[0113] Beer is manufactured using a part of the heat-treated fermented stock solution. The use ratio of the heat-treated fermentation stock solution in the total fermentation stock solution is 12.5 to 25% by weight. That is, suspend 7.5 kg of barley malt in 20 L of warm water at 59°C and keep it for 5 minutes, raise the temperature to 65°C and keep it for 25 minutes to obtain wort, then raise the temperature of the wort to 130°C and keep it for 30 minutes to obtain heat-treated Fermentation stock solution. Next, a suspension in which 22.5 kg of barley malt was suspended in 100 L of warm water at 59° C. was prepared. These were mixed according to the ratio described in Table 4, and held at 65° C. for 40 minutes. After the temperature was raised to 77°C, the husk was removed by filtration. Adjust the sugar content to 12w / w%, add hops and boil for about 1 hour, then cool to about 10°C, add yeast for fermentation. Filtration takes place after about 1 week of ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com