Steel rail rubber vibration and noise reduction insertion strip

A technology of rubber vibration damping and steel rails, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems that it is difficult to meet the higher requirements of rail vibration and speed, the combination of concrete slabs and bricks is not firm, and the strength of asphalt pavement is weak, so as to facilitate cleaning Cleaning management, beautiful and comfortable appearance, and the effect of exempting from maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

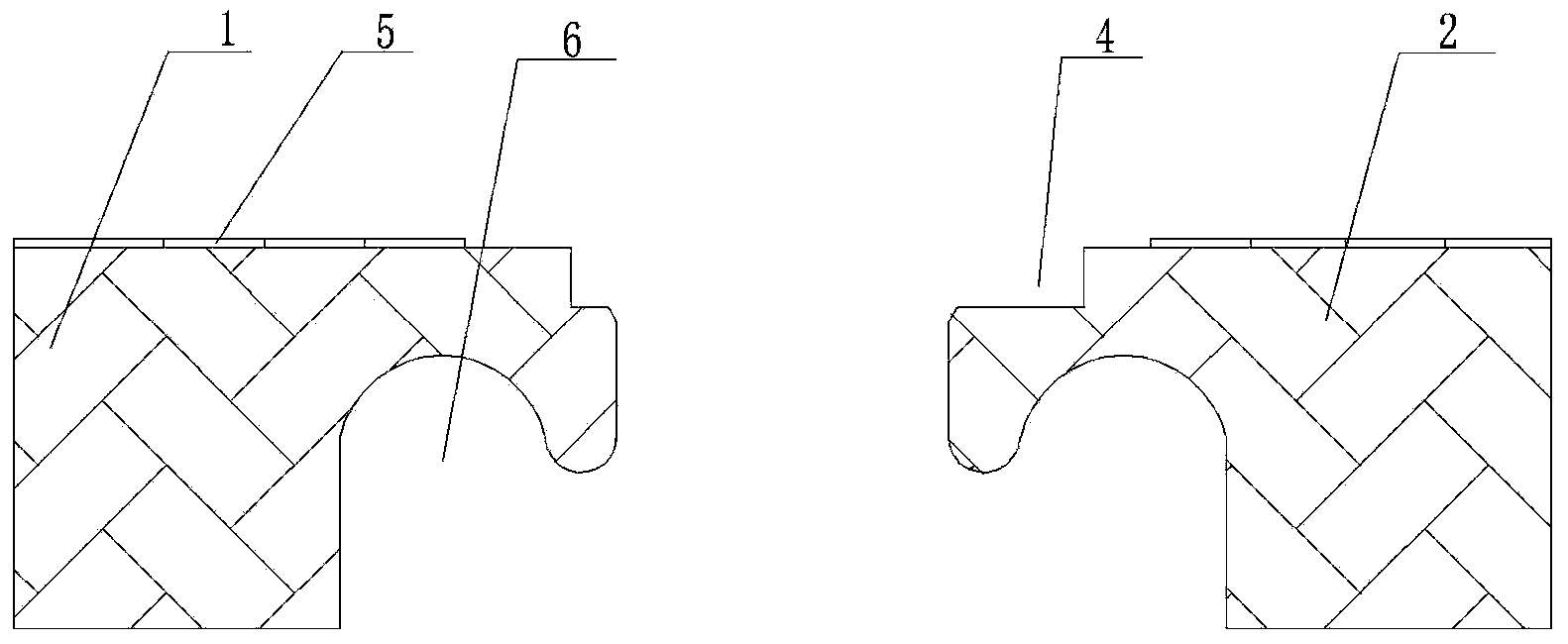

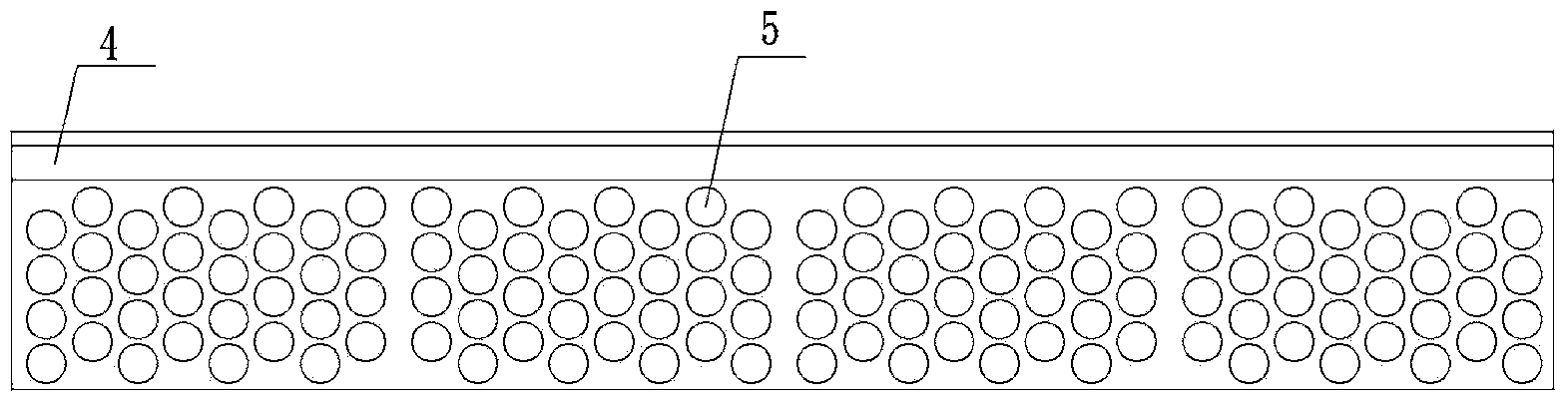

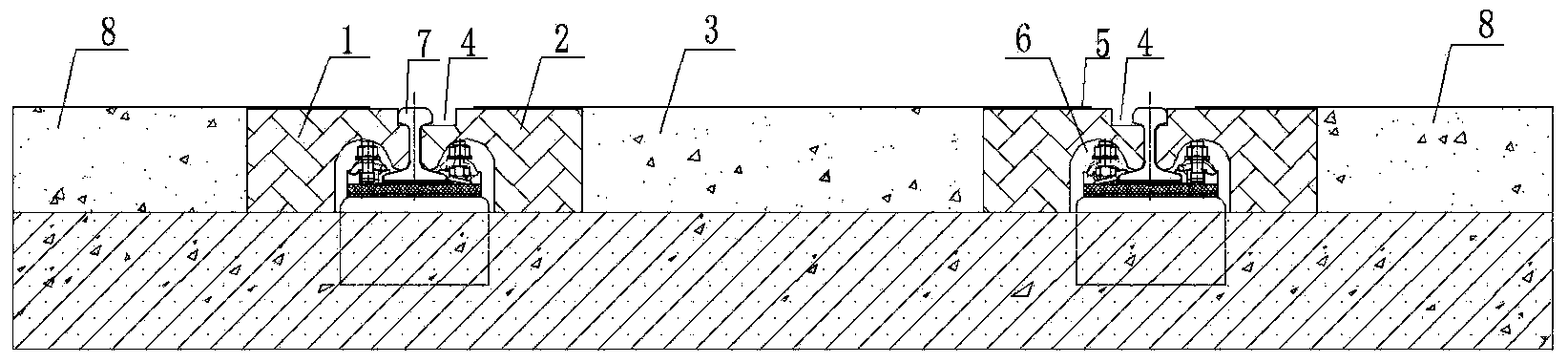

[0026] see Figure 1 ~ Figure 2 , The rail rubber vibration-damping and noise-reducing fillet of the present invention includes a side bar 1 and a middle bar 2, the side bar 1 is installed on the non-working side of the two rails, and the middle bar 2 is installed on the working side of the rail.

[0027] Wherein, the side strip 1 includes a side strip body, and one side of the side strip body extends outwards with a side strip flange, and a notch 6 is provided on the lower side of the side strip flange, so as to facilitate docking and protect the fastener during installation.

[0028] The middle bar 2 includes a middle bar body, one side of the middle bar body extends out the middle bar flange, and the upper side of the middle bar flange is provided with a rim groove 4, and the rim groove 4 is used for train wheel The inner rim leaves a corresponding gap, preferably, the rim groove can be a square groove or a circular groove; a gap is also arranged on the lower side of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com