Floating seat balanced high temperature regulating cut-off valve

A technology of floating valve seat and cut-off valve, which is applied in the direction of valve details, valve lift, valve device, etc., can solve the problems of high temperature resistance, low temperature resistance, and difficulty in sealing at the same time, so as to achieve good sealing effect and high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

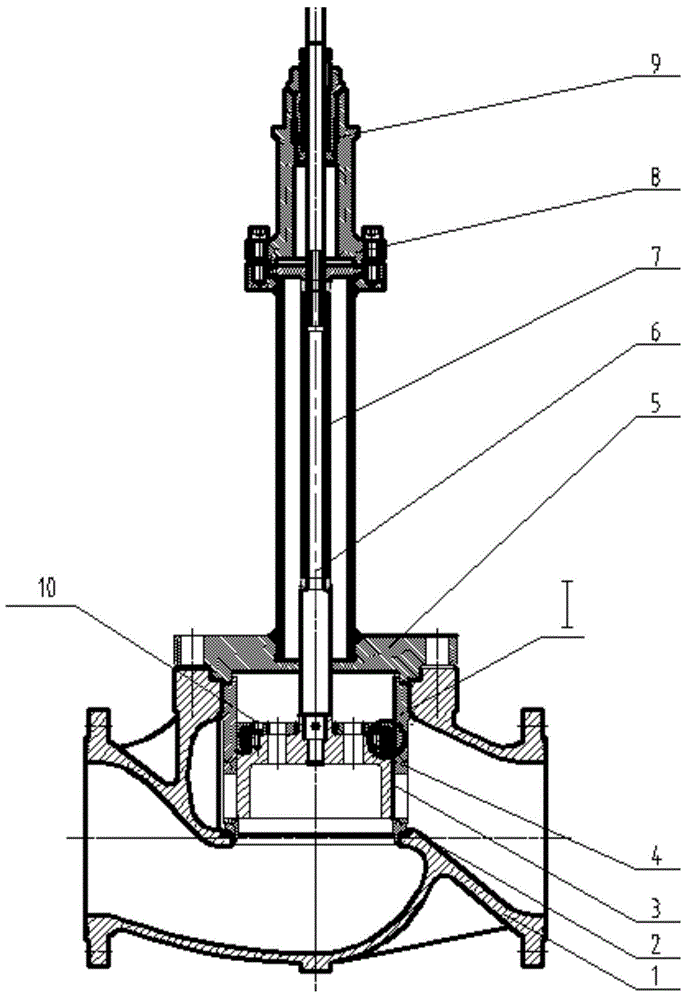

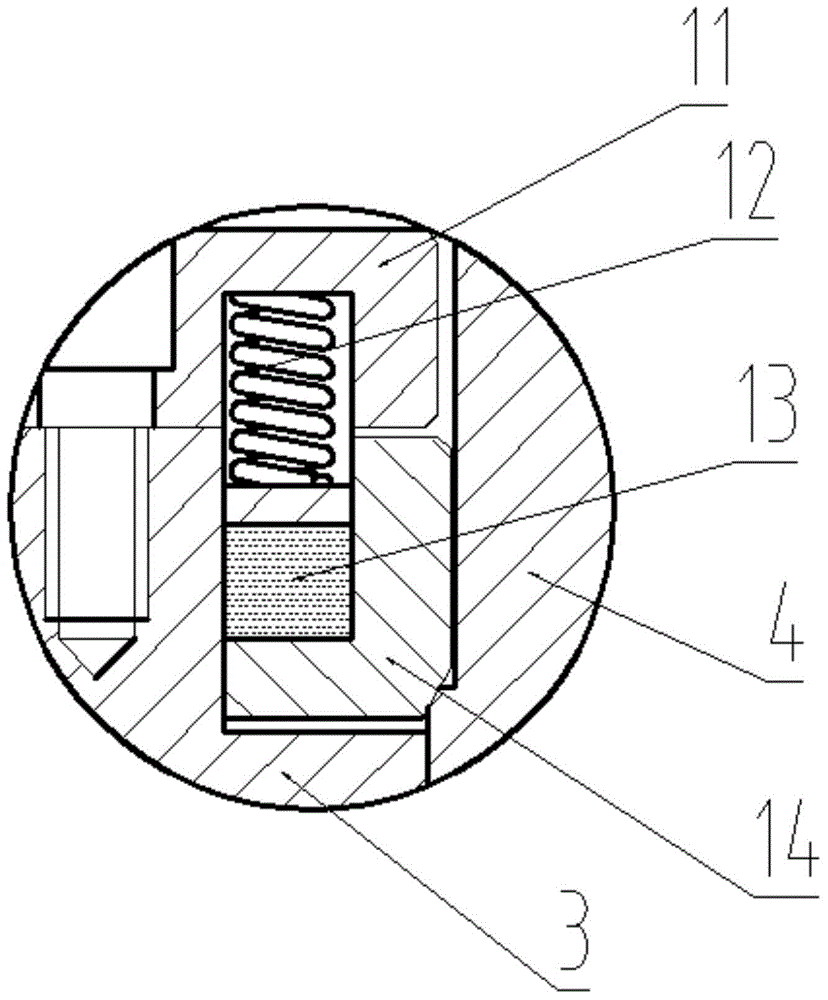

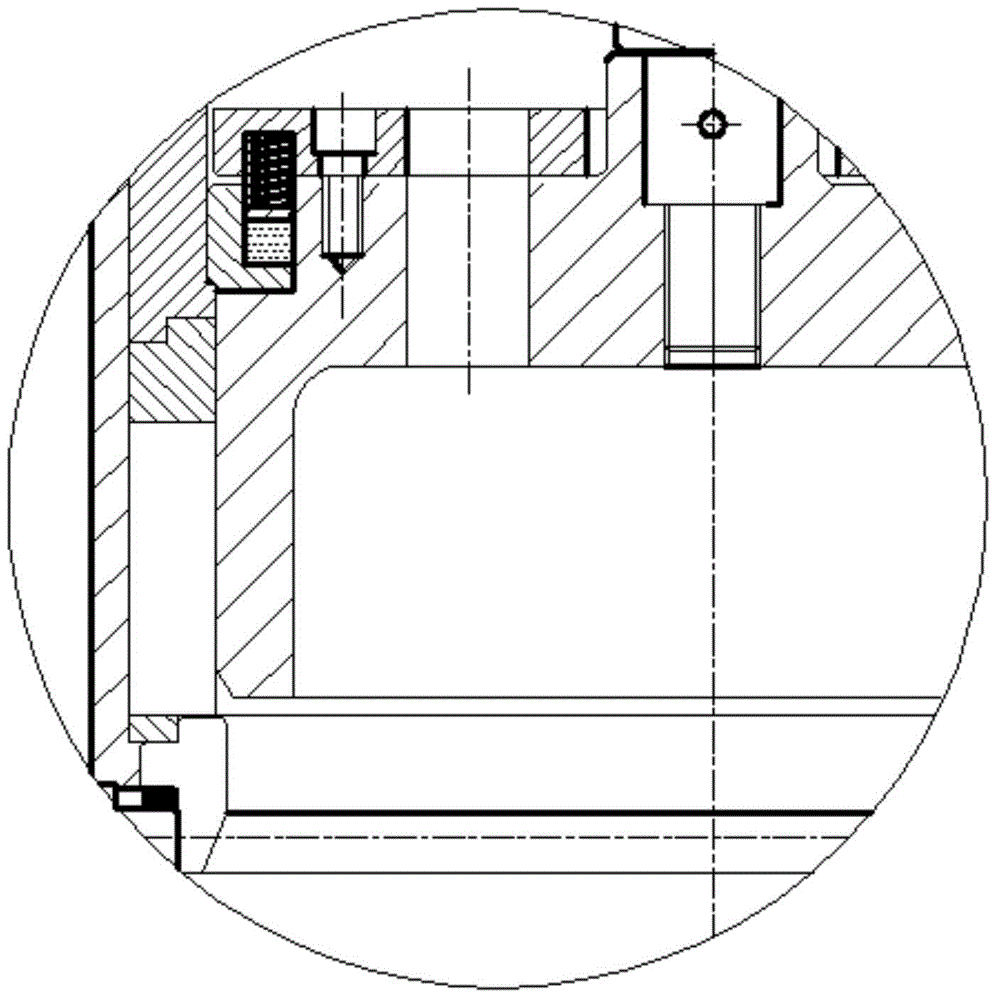

[0018] Such as Figure 1-4 As shown, the present invention provides a floating valve seat balanced high temperature regulating shut-off valve, comprising a valve body 1, a valve seat 2, a valve core 3, a sleeve 4, a floating valve seat 14 on the valve core and a valve stem 6, the valve core 3 is set in the valve body 1, and the valve body 1 is provided with a valve seat 2 at the position between the water inlet and the water outlet, and the valve core 3 is arranged on the valve seat 2 so as to be openable and A first lower sealing surface is provided at the fitting place of the seat 2, and a second lower sealing surface is arranged at the fitting place of the valve seat 2 and the valve core 3; the first lower sealing surface and the second lower sealing surface form a lower sealing pair.

[0019] The valve seat 2 is fixed in the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com