Universal joint

A general-purpose joint and bolt technology, applied in the direction of pipe/pipe joint/pipe fitting, passing element, sealing surface connection, etc., can solve the problems of poor sealing performance, achieve good sealing performance, ideal structural design, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

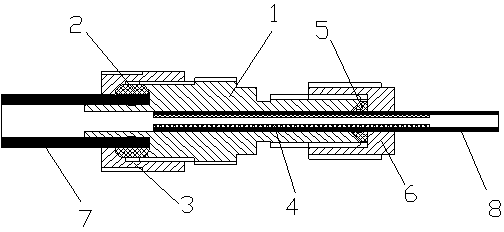

[0021] The present invention is used for the connection of gas chromatography gas pipelines:

[0022] The thick plastic tube (7) led from the gas cylinder is put on one end of the smooth tube of the bolt (1), and then the sealing ferrule (a) is put on the plastic pipe (7), so that the sealing ferrule (a) is stuck on the screw thread in the curved groove on the end, then tighten the jam nut (A).

[0023] Put the gas chromatographic gas source inlet plastic pipe joint (8) on the support tube (4), then penetrate the sealing ferrule (b), and insert the threaded end of the bolt (1), so that the sealing ferrule is stuck on the bolt (1 ) in the tapered groove, tighten with the lock nut (B), and the connection between the thick tube and the thin tube is completed.

[0024] The joint can withstand 2.5MPa pressure during use without loosening and shifting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com