Method for on-line temperature monitoring of exciting winding of plasma Hall effect thruster

A technology of excitation winding and Hall effect, applied in thermometers, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve the problem of adding additional measuring couples, etc., and achieve the effect of simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

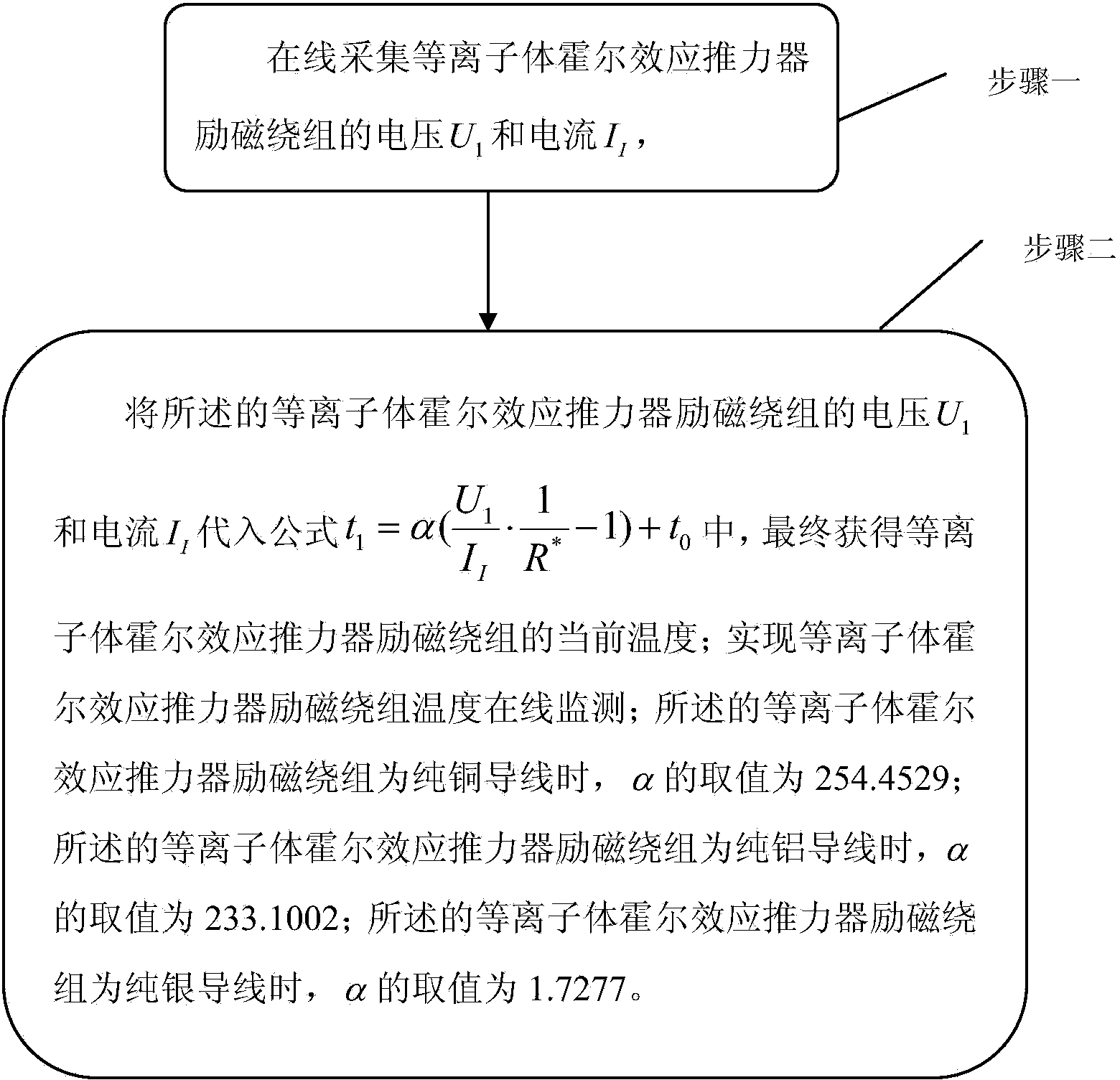

[0022] Specific implementation mode one: see figure 1 Illustrate this embodiment mode, the on-line monitoring method of excitation winding temperature of plasma Hall effect thruster described in this embodiment mode, its concrete steps are,

[0023] Step 1. Online collection of the voltage U of the excitation winding of the plasma Hall effect thruster 1 and current I I ,

[0024] Step 2, the voltage U of the excitation winding of the plasma Hall effect thruster 1 and current I I Into the formula

[0025] t 1 = α ( U 1 I I · 1 R * - 1 ) + t 0 - - - ( 1 ...

specific Embodiment approach 2

[0034] Specific implementation mode two: see figure 1 This embodiment is described. The difference between this embodiment and the online monitoring method for the excitation winding temperature of the plasma Hall effect thruster described in the first embodiment is that the online collection of the voltage U1 of the excitation winding of the plasma Hall effect thruster Implemented with voltage transformers.

specific Embodiment approach 3

[0035] Specific implementation mode three: see figure 1 This embodiment is described. The difference between this embodiment and the online monitoring method for the excitation winding temperature of the plasma Hall effect thruster described in the first or second specific embodiment is that the online collection of the excitation winding temperature of the plasma Hall effect thruster Current II is realized with a current transformer.

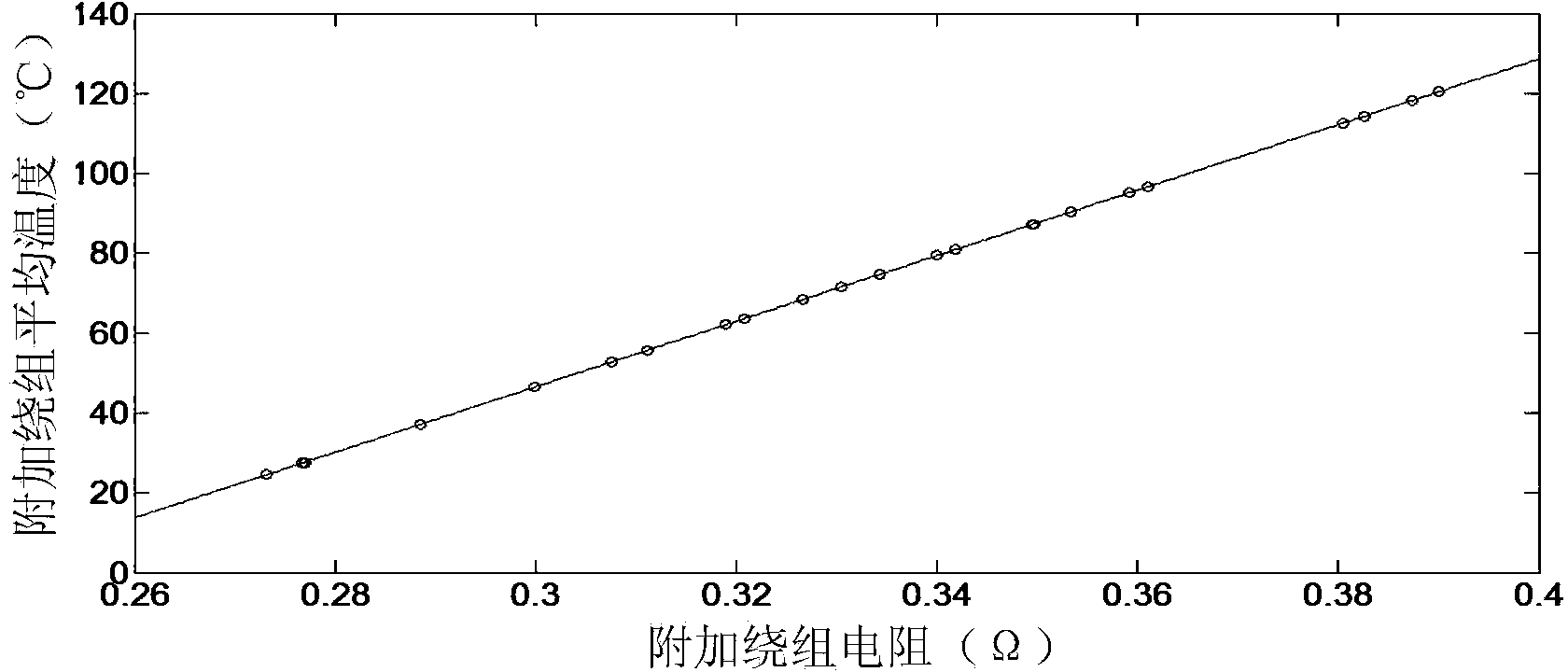

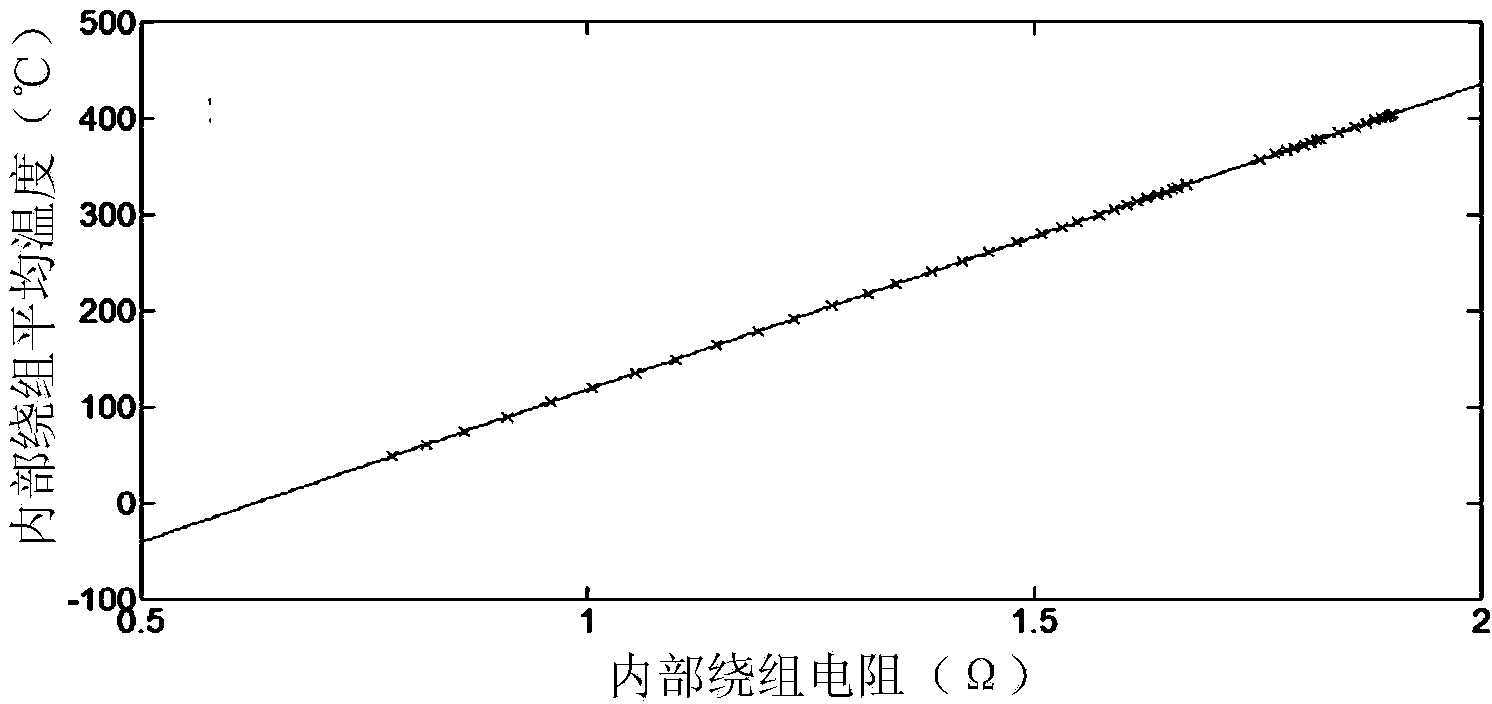

[0036] The resistance of all substances will change due to changes in temperature. For most metals and most alloys, the resistance increases with the increase of temperature. In the prior art, in order to reduce the difficulty of system design and improve reliability, There is no effective method for coil temperature monitoring of thruster space flight, but the present invention verifies the applicability of formula (1) in the range of 30 degrees to 500 degrees, without changing the overall design of the space propulsion system, The monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com