Sock stretching detection instrument

A technology for detectors and socks, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of reduced recovery, unreachable detection, and inaccurate data, so as to improve efficiency and accuracy, and facilitate operation , the effect of testing the accuracy of the data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

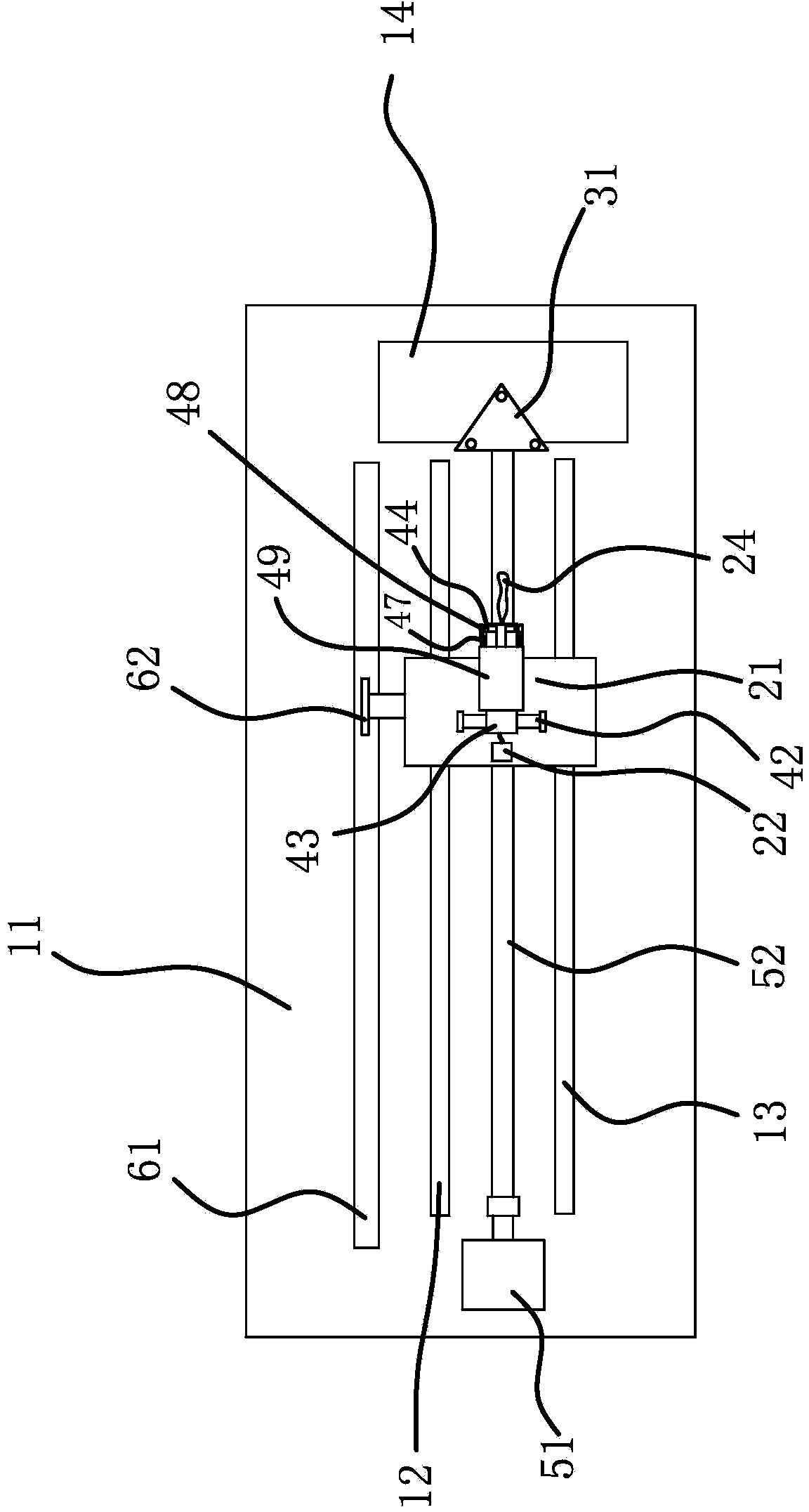

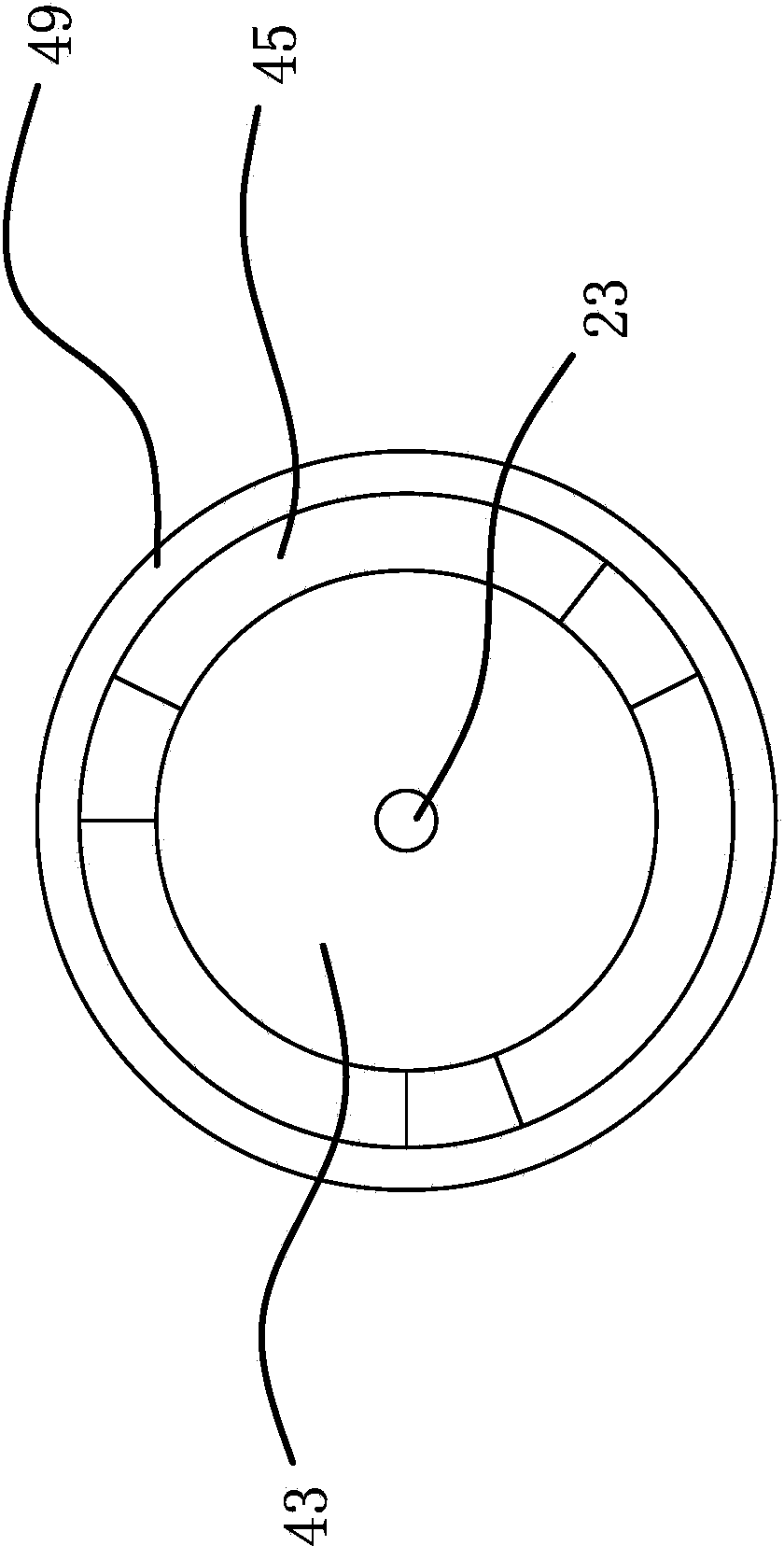

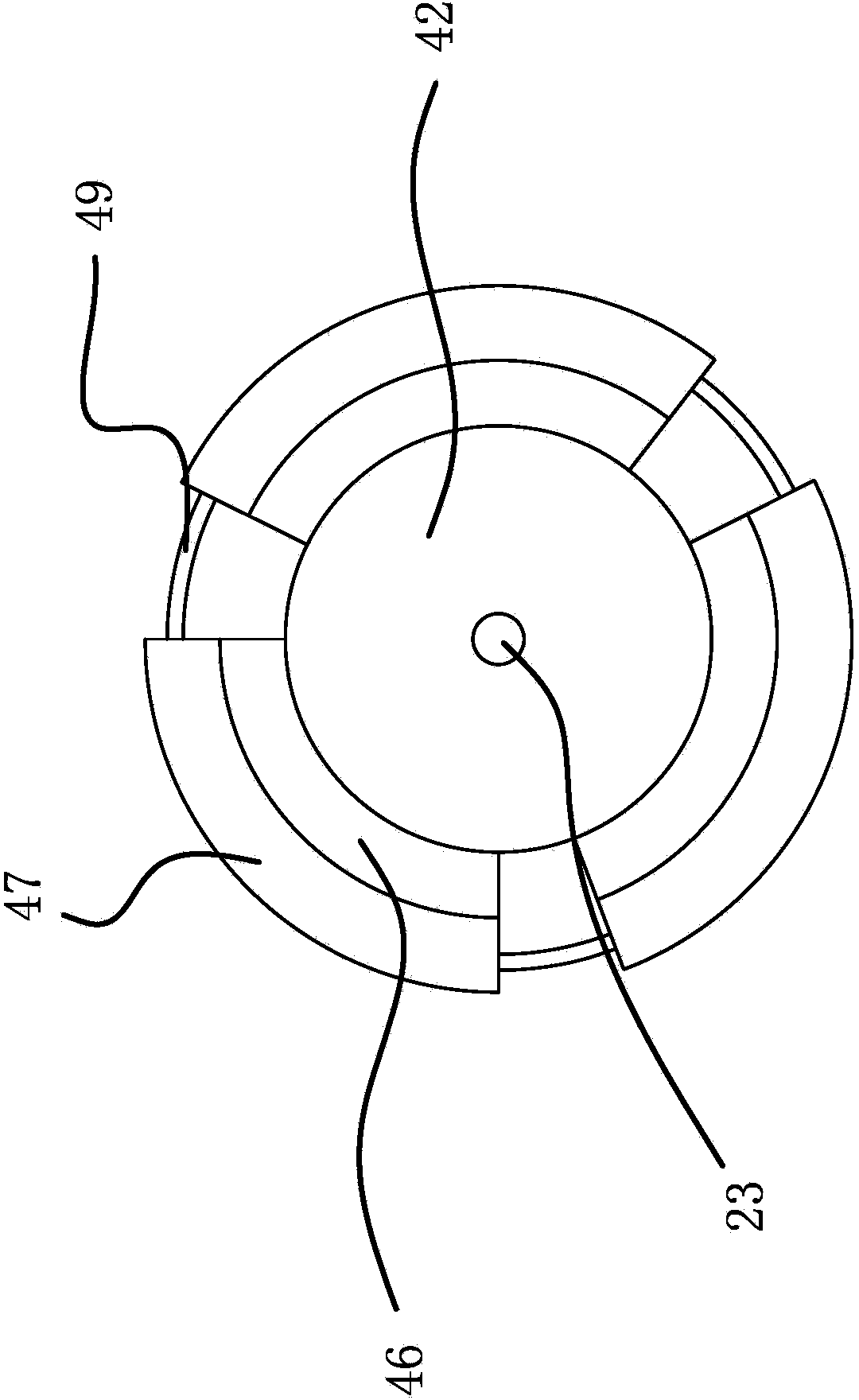

[0030] Such as Figure 1 to Figure 5 Shown, a kind of tensile tester of socks, tensile tester comprises frame 11, is provided with slide rail, fixed collet 31 and movable collet on frame 11, and slide rail is fixed on frame 11, and slide rail There are two, including slide rail one 12 and slide rail two 13, on the slide rail, slide block 21 is slidably connected, and movable chuck is fixed on the slide block 21, and the movable chuck includes support 42, sleeve pipe 43, clamp ring 45 and Movable sleeve 49, support 42 is fixed on the slide block 21, sleeve pipe 43 one end is connection end, the other end is fixed end, connection end and support 42 are fixed, sleeve pipe 43 is provided with external thread near the peripheral surface of connection end, and movable sleeve 49 has a limit hole and a mounting hole with internal thread, the movable sleeve 49 is placed on the sleeve 43, the mounting hole is threaded with the sleeve 43, the length of the movable sleeve 49 is less than ...

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the driving mechanism includes a cylinder, the cylinder is fixed on the frame and is located between the fixed seat and the slider, and the end of the telescopic rod of the cylinder is fixed on the slider. In addition, a pressure-sensitive sensor is also fixed between the telescopic rod of the cylinder and the slide block. The telescopic control slider of the cylinder piston rod moves back and forth along the guide rail, so as to realize the relative movement of the movable chuck relative to the fixed chuck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com