A light guide plate and a backlight module

A technology of light guide plate and light source, which is applied in the direction of light guide, optics, electric light source, etc., and can solve the problems of difficult preparation of syringe capacity injection mold, difficulty in large-scale, thick thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

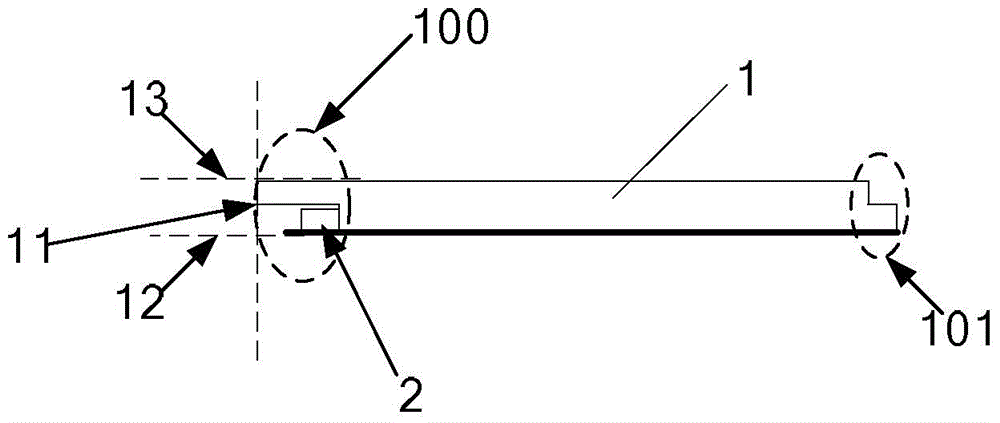

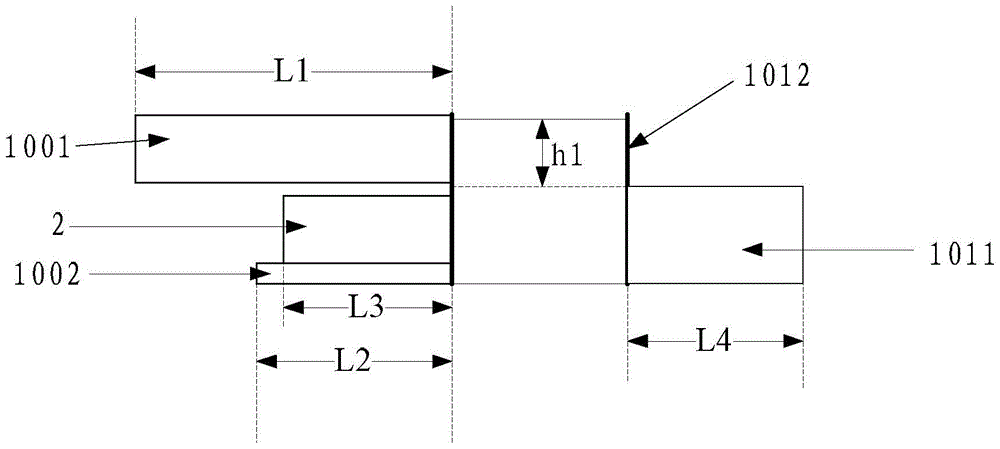

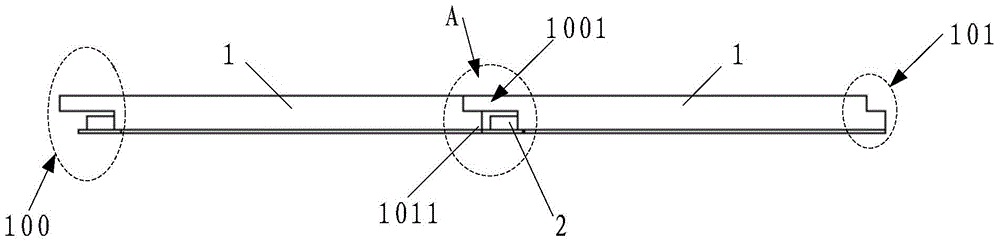

[0042] An embodiment of the present invention provides a light guide plate. The light guide plate includes several sub-light guide plates; the sub-light guide plates include a light incident surface, a reflection surface and a light exit surface. A light source groove is provided on the light incident surface of the sub-light guide plate, and the light source groove is used to place a light source; a connecting piece is provided on the opposite side of the light incident surface; wherein, the connecting piece is used for The sub-light guide plates in the light guide plates are connected to each other.

[0043] Optionally, a first connecting member may be provided on the side opposite to the light-incident surface, and the two sub-light guide plates may be assembled and connected by the first connecting portion of one sub-light guide plate and the light source groove of the other sub-light guide plate, In this way, a large-sized light guide plate can be assembled from small-siz...

Embodiment 2

[0058] Embodiments of the present invention provide a figure 1 The manufacturing method of the sub-light guide plate shown, the method includes:

[0059] S1, prepare and can form such as figure 1 and Figure 6 Injection mold for the shape of the sub-LGP shown.

[0060] S2. Using an injection device to inject light guide plate material into the injection mold to form a sub-light guide plate primary plate.

[0061] S3. Using methods such as lazer (laser), etching (etching) or indentation (indentation) to process light guide point patterns on the primary sub-light guide plate to form a sub-light guide plate.

Embodiment 3

[0063] An embodiment of the present invention provides a light guide plate. The light guide plate includes several sub-light guide plates; the sub-light guide plates include a light incident surface, a reflection surface and a light exit surface. A light source groove is provided on the light incident surface of the sub-light guide plate, and the light source groove is used to place a light source; connecting pieces are provided on two adjacent sides of the light incident surface; wherein, the connection The components are used to connect the sub-light guide plates in the light guide plate to each other.

[0064] Such as Figure 9 Shown is a top view of the sub-light guide plate 1, Figure 10 for Figure 9 A cross-sectional view of the sub-light guide plate shown in the direction A1-A2; Figure 11 for Figure 9 The shown sub-light guide plate is a cross-sectional view along the B1-B2 direction.

[0065] Such as Figure 10 As shown, the right side of the sub-light guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com