Hot-rolled wire rod for manufacturing high-strength container self-tapping screws and production method thereof

A technology for self-tapping screws and hot-rolled wire rods is applied in manufacturing tools, rolling mill control devices, metal rolling, etc., and can solve the problems that do not involve the production method of high-strength container self-tapping screws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] It is used to manufacture hot-rolled wire rods for high-strength container self-tapping screws. Its chemical composition consists of the following substances by weight percentage (%): C: 0.28%, Mn: 0.86%, Si: 0.06%, P: 0.02%, S : 0.011%, Cr: 0.51%, and the rest are Fe, which are listed in Table 1; the diameter φ8.0mm hot-rolled wire rod produced by the production method of the present invention, the wire rod tensile strength, elongation, and area reduction are listed in Table 2 Among them, 1 / 3 cold heading is qualified, and it has good cleaning performance, which meets the production requirements of high-strength self-tapping screws.

[0077] 1. Smelting

[0078] Using converter or electric furnace for smelting, tapping endpoint control: [C]0.06~0.10%, [P]≤0.015%, [S]≤0.018%. Tapping temperature: 1640-1690°C; implement double slag blocking process: add slag blocking plug before tapping, and add slag blocking rod or slag blocking cone when tapping 4 / 5; alloy and recarbu...

Embodiment 2

[0123] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

Embodiment 3

[0125] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

[0126] Schedule:

[0127] Table 1 Chemical composition (%) table of the embodiment of the present invention

[0128] Example C Si mn P S Cr Fe 1 0.28 0.06 0.86 0.020 0.011 0.51 margin 2 0.29 0.06 0.88 0.017 0.010 0.54 margin 3 0.27 0.07 0.90 0.019 0.010 0.57 margin

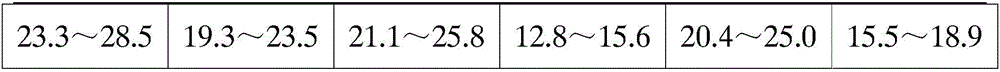

[0129] Table 2 performance table of the embodiment of the present invention

[0130]

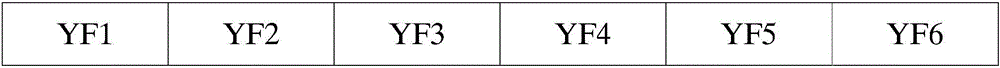

[0131] Table 3 Roll Diameter (mm) of Roughing Mill

[0132] Example CF1 CF2 CF3 CF4 CF5 CF6 1 548 548 548 467 467 467 2 548 548 548 467 467 467 3 536 536 536 459 459 459

[0133] Table 4 Rolled piece inlet temperature and outlet temperature (°C) table

[0134] serial number Example 1 Example 2 Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com