Disc type filtration system

A technology of disc filter and filter machine, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc. It can solve the problems of vacuum pump damage, increased infrastructure investment, low pressure, etc., to reduce the layout height and increase interception time and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

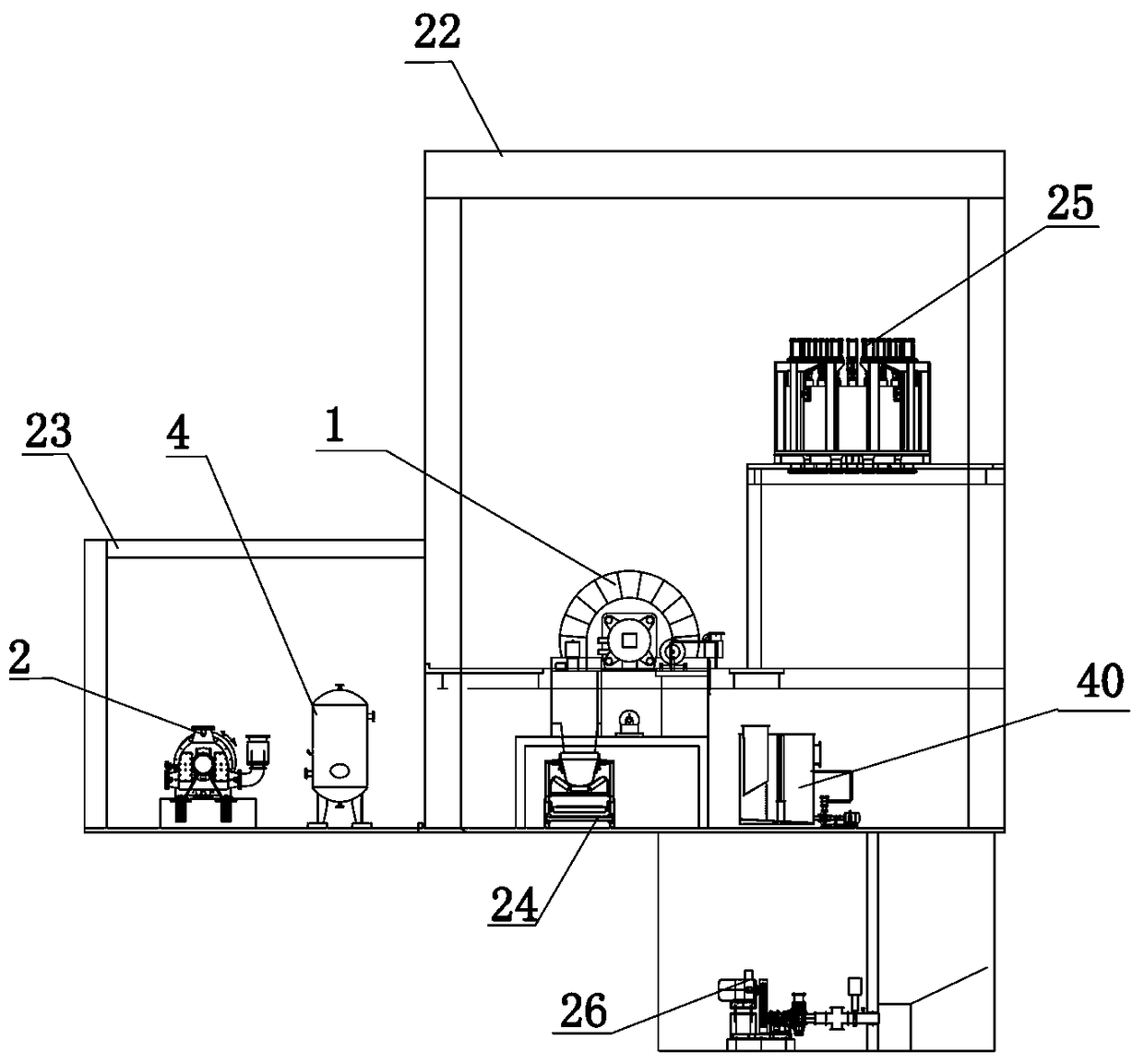

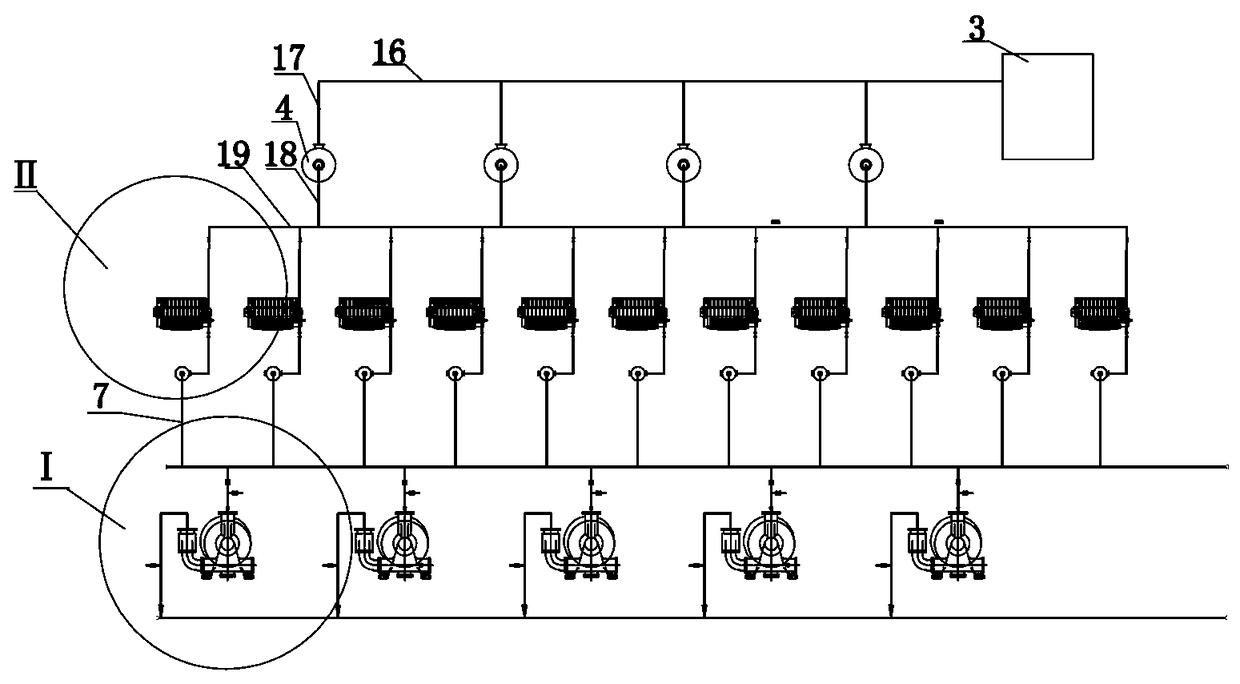

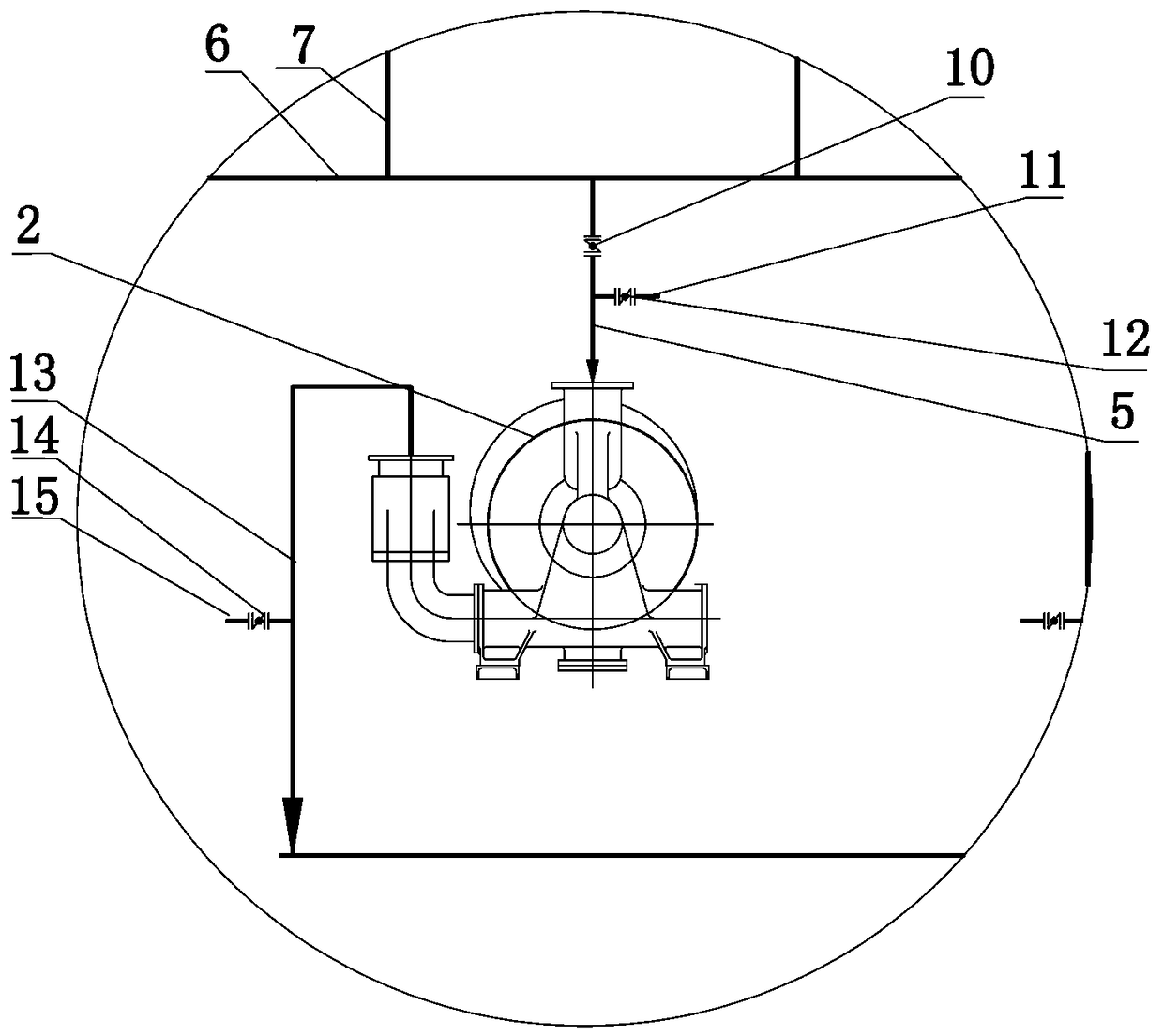

[0042] Such as Figure 1-7 As shown, in the disc filter system of the present invention, the number of filters is 10 as an example, and it is characterized in that it comprises a filter workshop 22, an air supply workshop 23, and the gas distributors in the filter workshop 22 and the air supply workshop 23 are arranged. system, the slurry distributor 25 set on the platform I of the filter workshop 22, the filtrate summarizing pump 26 set on the platform III below the ground of the filter workshop 22, and the drainage pump 26 set on the floor of the filter workshop 22 The material belt conveyor 24, the forced gas-liquid separation subsystem 40 arranged inside the gas distribution subsystem, wherein the gas supply workshop 23 is a closed soundproof workshop, and multiple single items of equipment in the two workshops are arranged ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com