Finite element analysis method for simulating ride comfort of entire vehicle under pulse input

A technology of pulse input and analysis method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of small improvement space and unsatisfactory smoothness, etc., to achieve improved ride comfort, ride comfort, The effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

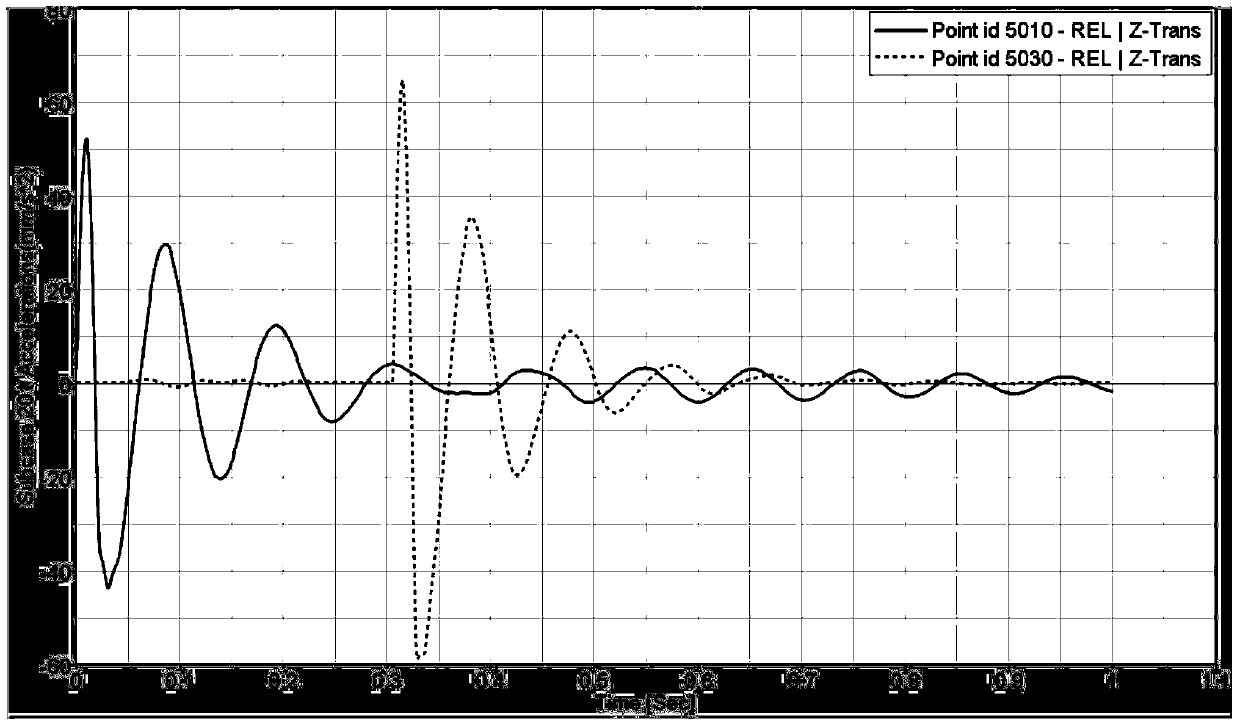

[0035] Calculate the speed of 30km / h for a certain model to pass through a 1 / 2 sinusoidal buffer strip with a size of 180mm*30mm, and output the vibration response of the wheel center and the steering wheel. The wheelbase of this model is 2548mm.

[0036] 1. Use computer software to establish a finite element model of a vehicle, including body, opening parts, chassis, interior and exterior accessories, etc., see figure 1 .

[0037] 2. Define the size model of the transient excitation buffer bar (this analysis takes 1 / 2 sinusoidal buffer bar as an example), see figure 2 .

[0038] 3. Calculate the loading parameters.

[0039] In the calculation of this example, the units are as follows: length (mm), time (s), weight (kg), density (kg / mm 3 ), the relevant parameters are:

[0040] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com