Basket Mill

A basket grinder and basket body technology, applied in the grinder field, can solve problems such as easy wear and blockage of the screen, affecting grinding efficiency and service life, and achieve the effects of improving production efficiency, not being easily deformed by pressure, and having a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

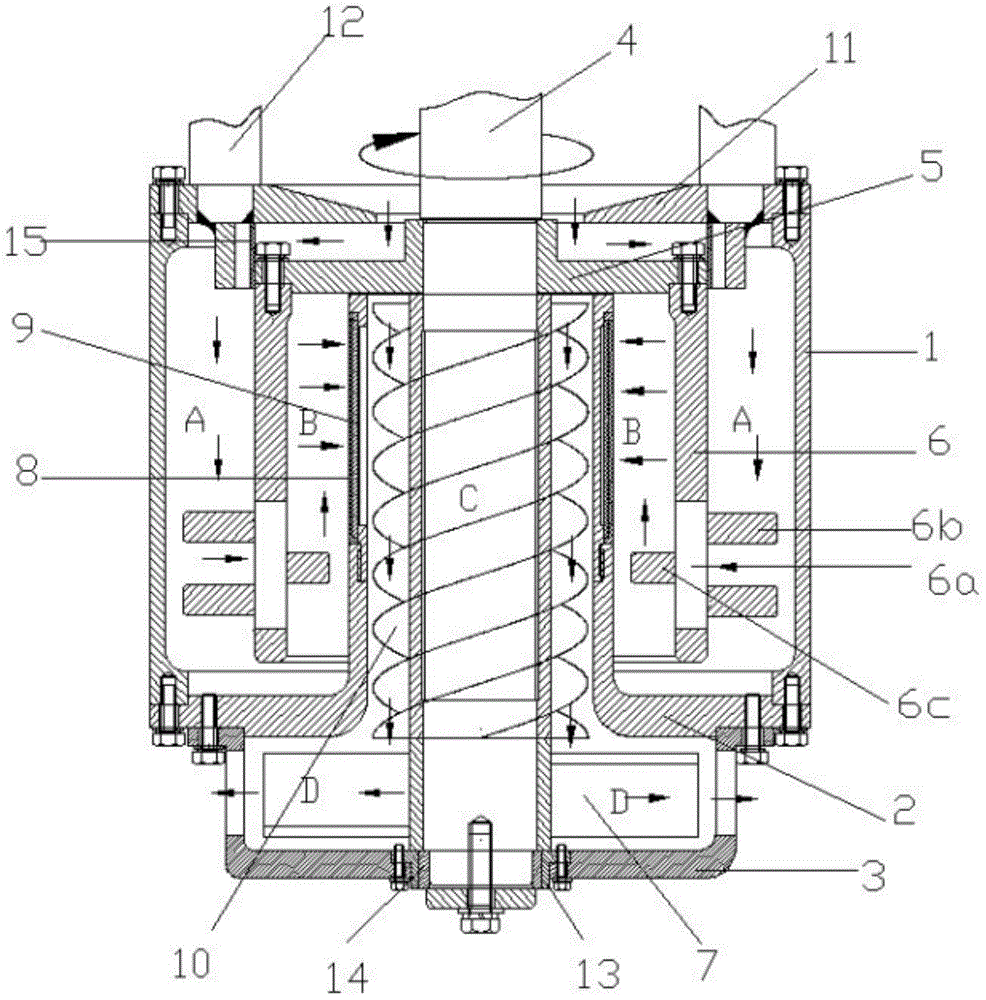

[0025] Embodiment 1: as figure 1 , image 3 with Figure 4 A basket grinder shown includes a grinding basket body 1, a grinding basket bottom 2 connected to the bottom of the grinding basket body, a bracket 3 supporting the grinding basket bottom, and a main shaft 4 driven by a motor, and the main shaft 4 runs through the grinding up and down in sequence Basket body 1, grinding basket bottom 2 and bracket 3, the grinding basket body 1 is provided with a centrifugal impeller 5 and a drum 6 in sequence from top to bottom, the centrifugal impeller 5 is fixed on the top of the drum 6, and the blades of the centrifugal impeller 5 It is a centrifugal back-curved blade, and the height of the blade decreases gradually along the radial direction; the drum 6 is fixed on the main shaft 4, and the lower end of the main shaft 4 is also fixed with a stirring device 7, which is arranged in the support 3, and the drum An annular first grinding passage is formed between the outer wall of 6 a...

Embodiment 2

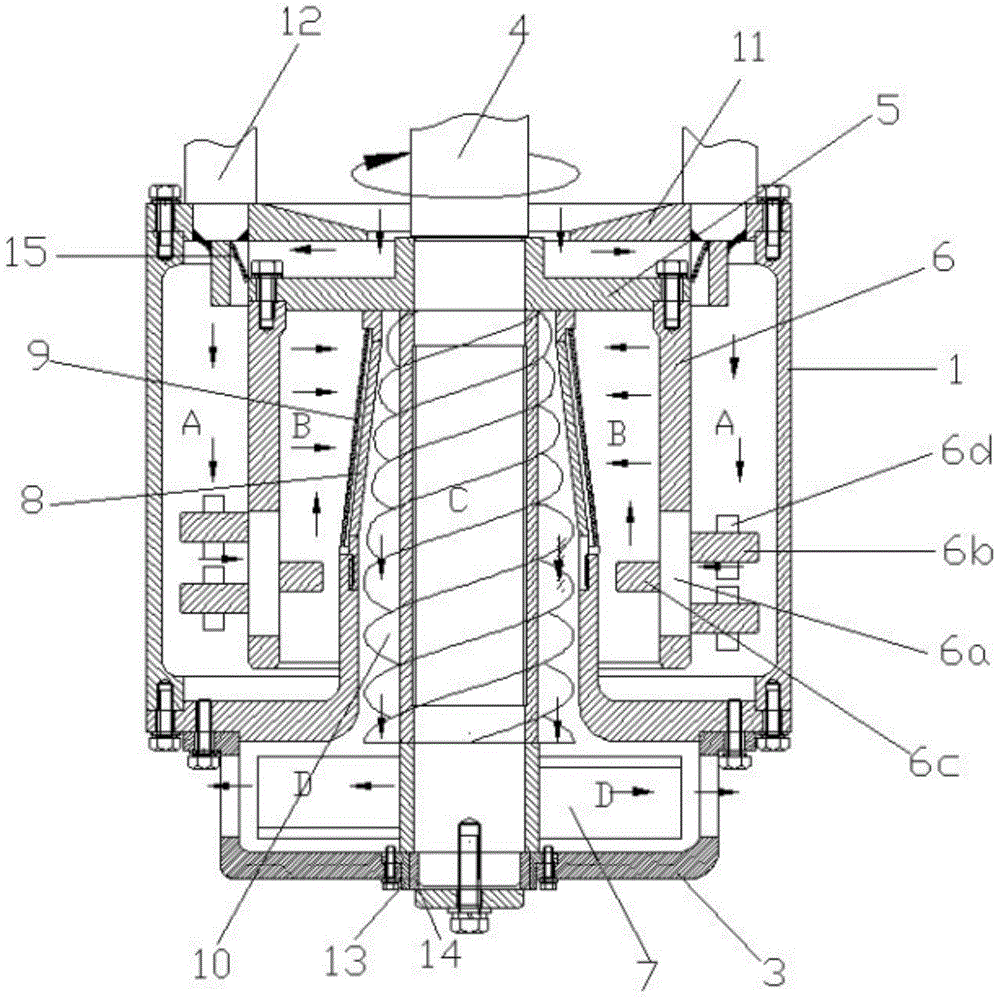

[0026] Embodiment 2: as figure 2 image 3 Figure 4 A basket grinder is shown, comprising a grinding basket body 1, a grinding basket bottom 2 connected to the bottom of the grinding basket body, a bracket 3 supporting the bottom of the grinding basket and a main shaft 4 driven by a motor, the main shaft 4 runs through the grinding basket up and down sequentially Body 1, grinding basket bottom 2 and bracket 3, the grinding basket body 1 is provided with a centrifugal impeller 5 and a drum 6 sequentially from top to bottom, the centrifugal impeller 5 is fixed on the top of the drum 6, and the blades of the centrifugal impeller 5 are Centrifugal back-curved blades, the height of the blades gradually decreases along the radial direction; the drum 6 is fixed on the main shaft 4, and the lower end of the main shaft 4 is also fixed with a stirring device 7, which is arranged in the bracket 3, and the drum 6 An annular first grinding channel is formed between the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com