Feeding device for numerical control horizontal metal band saw machine

A technology for metal bands and sawing machines, applied in metal sawing equipment, sawing machine accessories, metal processing, etc., can solve the problems of inability to realize automatic selection of materials, inconvenient operation, etc., and achieve small changes, simple operation, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

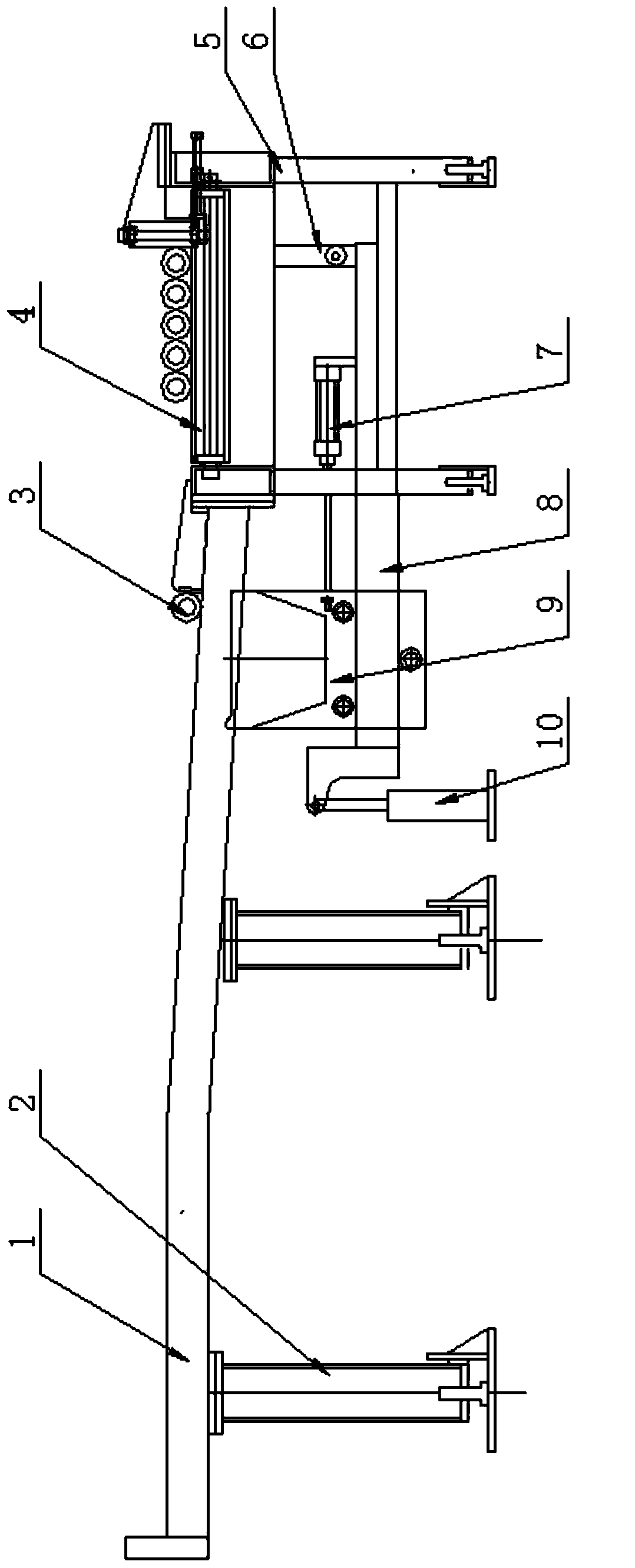

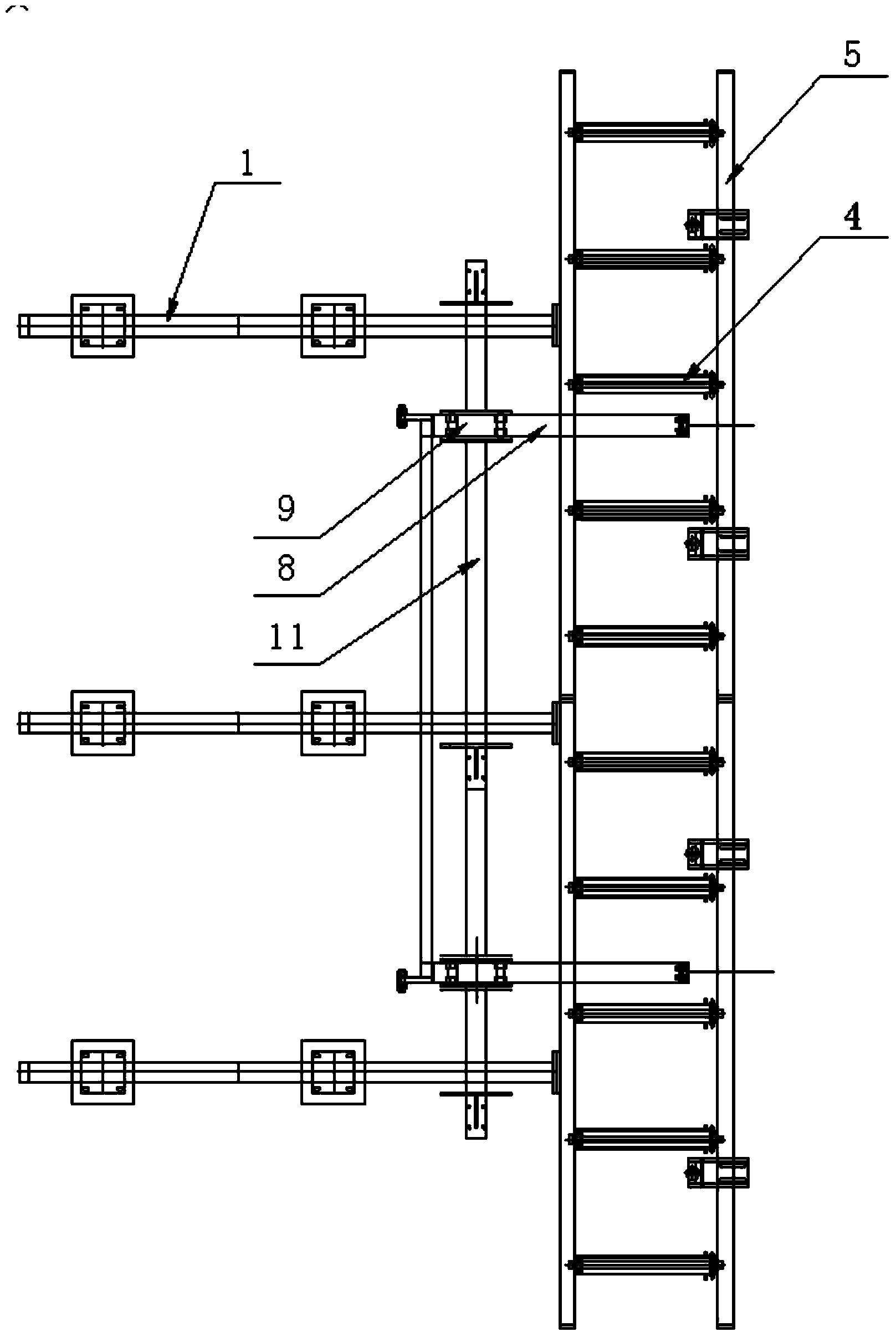

[0014] A feeding device for a numerically controlled horizontal metal band saw machine, comprising a material rack 1 and a conveying roller frame 5, on which a plurality of conveying rollers 4 are installed at intervals, and the bottom of the material frame is a support column 2. Its innovation is that it also includes a lifting bracket 8 and a material selection seat 9. The lifting bracket is composed of at least two horizontal brackets and a longitudinal bracket. , the longitudinal support of the lifting support is connected with the push rod of the vertical hydraulic cylinder 10 fixed on the ground, and the material selection seat is all slid on the horizontal support of the lifting support, and the mate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap