Method for processing valve core in oil cooler

A processing method and oil cooler technology, which are applied to valve devices, cocks including cutting devices, engine components, etc., can solve the problems of low machining accuracy and difficult operation, and achieve the effects of improving turning machining accuracy and machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

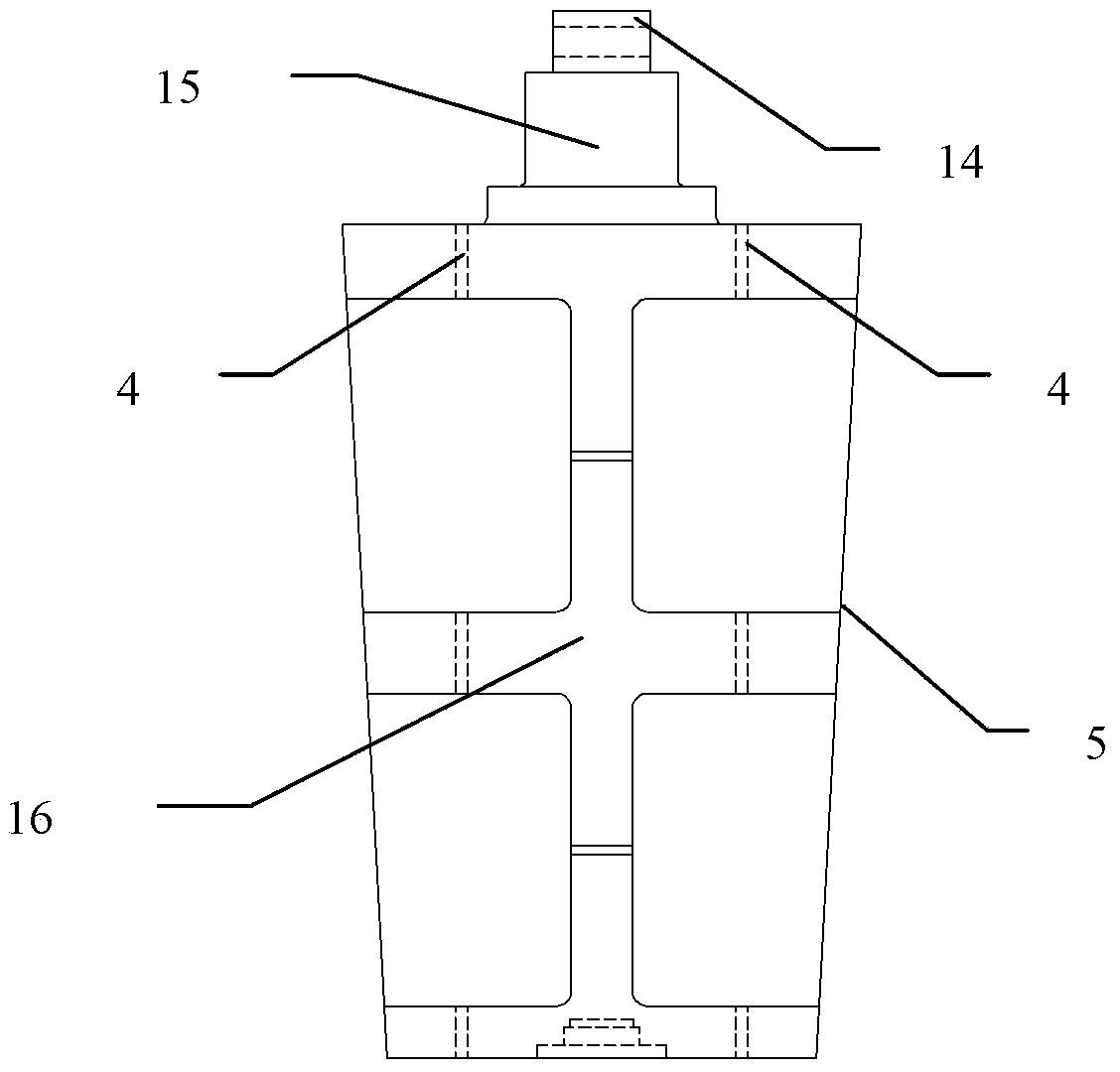

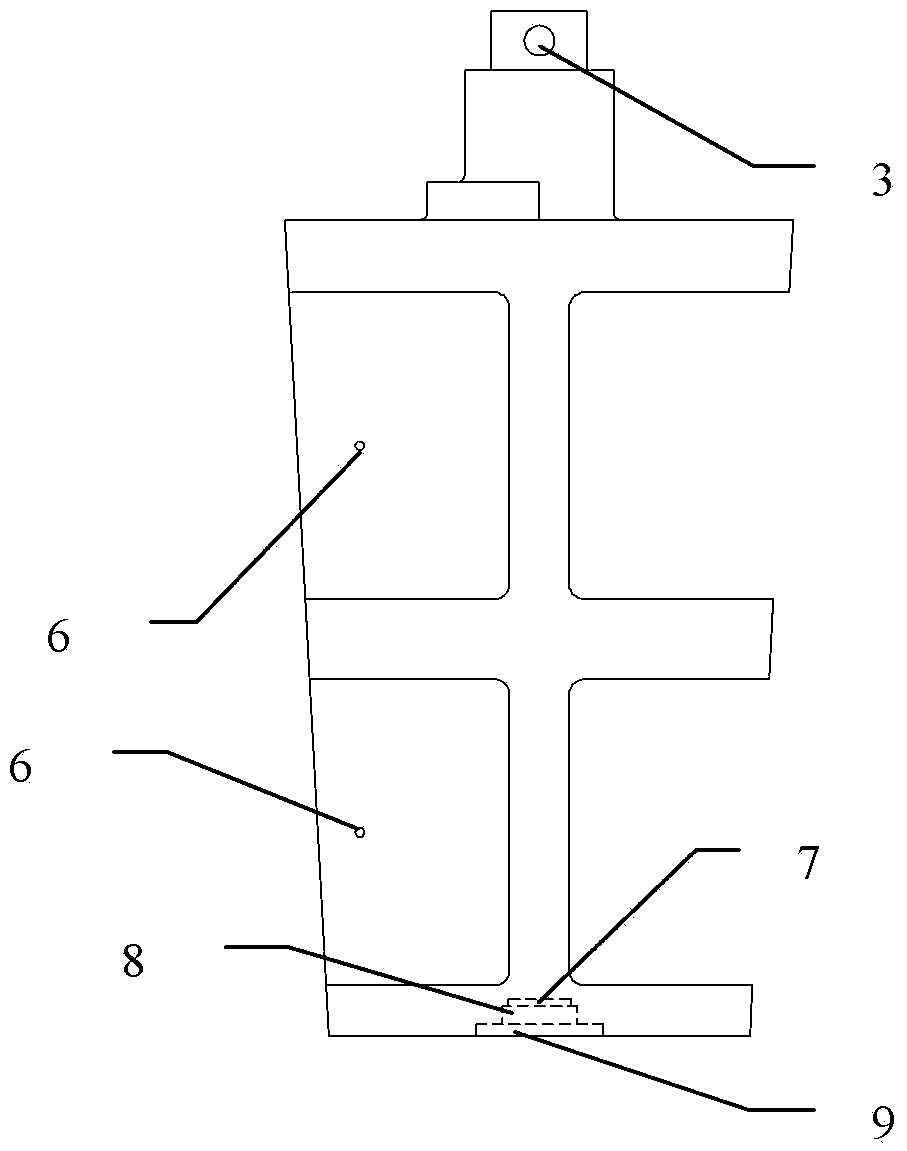

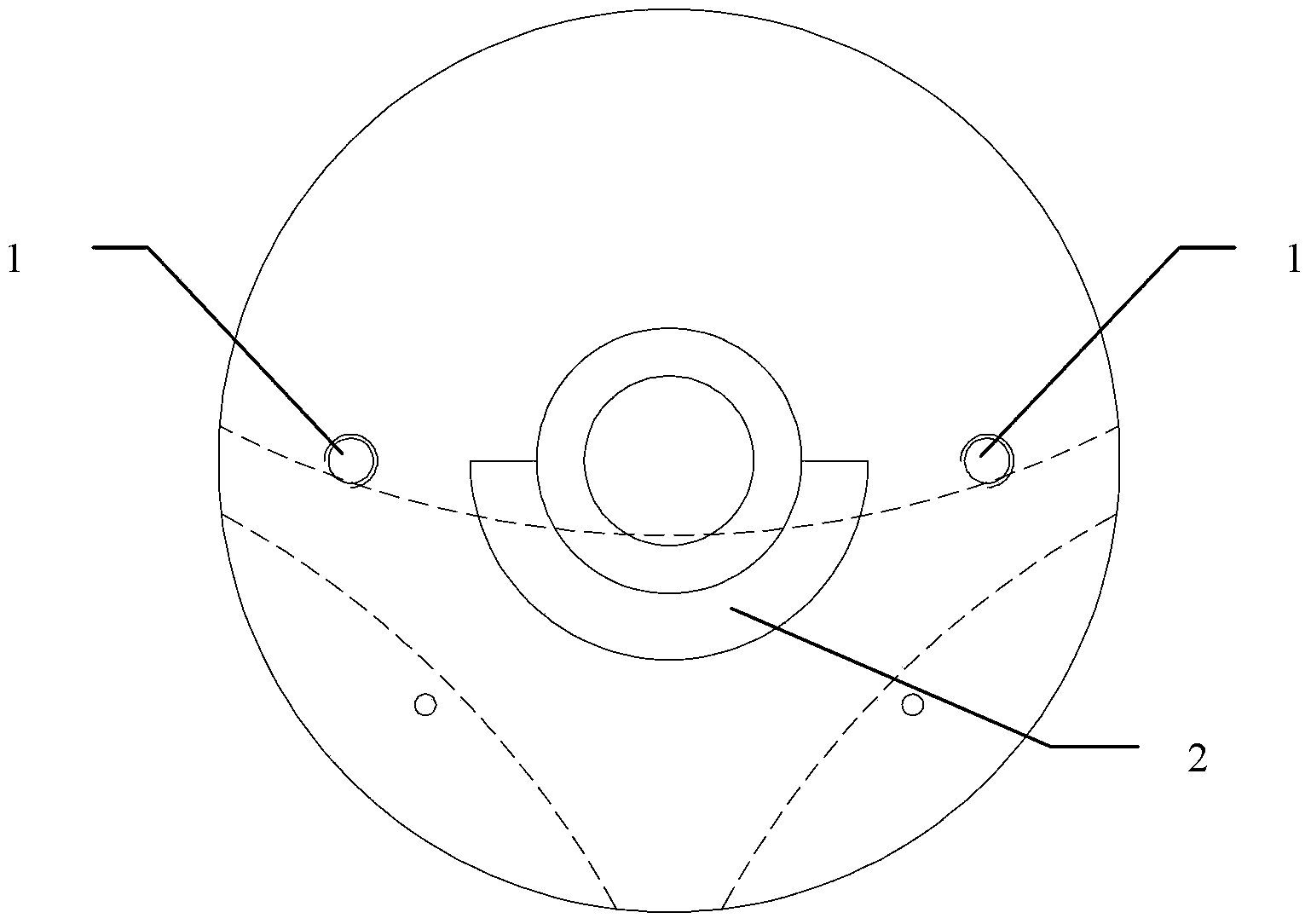

[0020] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, a kind of processing method of valve core for oil cooler, it is realized by the following steps:

[0021] Step 1. Roughly process the original material to obtain the rough-processed valve core for the oil cooler. The rough-processed valve core for the oil cooler includes the No. 1 cylinder (14), the No. 2 cylinder (15), the semicircular arc surface ( 2) and the cone (16), the lower surface of the No. 1 cylinder (14) and the upper surface of the No. 2 cylinder (15) are fixed, and the No. 1 cylinder (14) and the No. 2 cylinder (15) are coaxial and semicircular The inner side of face (2) is fixed with the end of the side of No. 2 cylinder (15), the upper surface of cone (16) is fixed with the lower surface of No. 2 cylinder (15), and cone (16) is connected with No. 2 cylinder ( 15) Coaxial;

[0022] Step 2, use a boring machine to drill a center hole in the center of the upper surface...

specific Embodiment approach 2

[0030] Embodiment 2. The difference between this embodiment and the method for processing a spool for an oil cooler described in Embodiment 1 is that the diameters of the center holes of the upper and lower outer circles in step 1 are 4mm-6mm.

specific Embodiment approach 3

[0031] Embodiment 3. The difference between this embodiment and the method for processing a spool for an oil cooler described in Embodiment 1 is that in step 3, the turning parameters when turning each outer circle and end face with a lathe are: The speed is 70r / min-90r / min, the feed rate is 0.2mm / r-0.4mm / r, and the cutting depth is 1.2mm-1.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com