Multi-freedom-degree manipulator fixture

A technology of manipulator and degrees of freedom, applied in the direction of manipulator, program-controlled manipulator, chuck, etc., can solve the problems of complex mechanism, difficulty in adjusting workpiece clamping force, and difficulty in adapting to workpieces of various sizes, and achieves safe and convenient operation and strong versatility. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

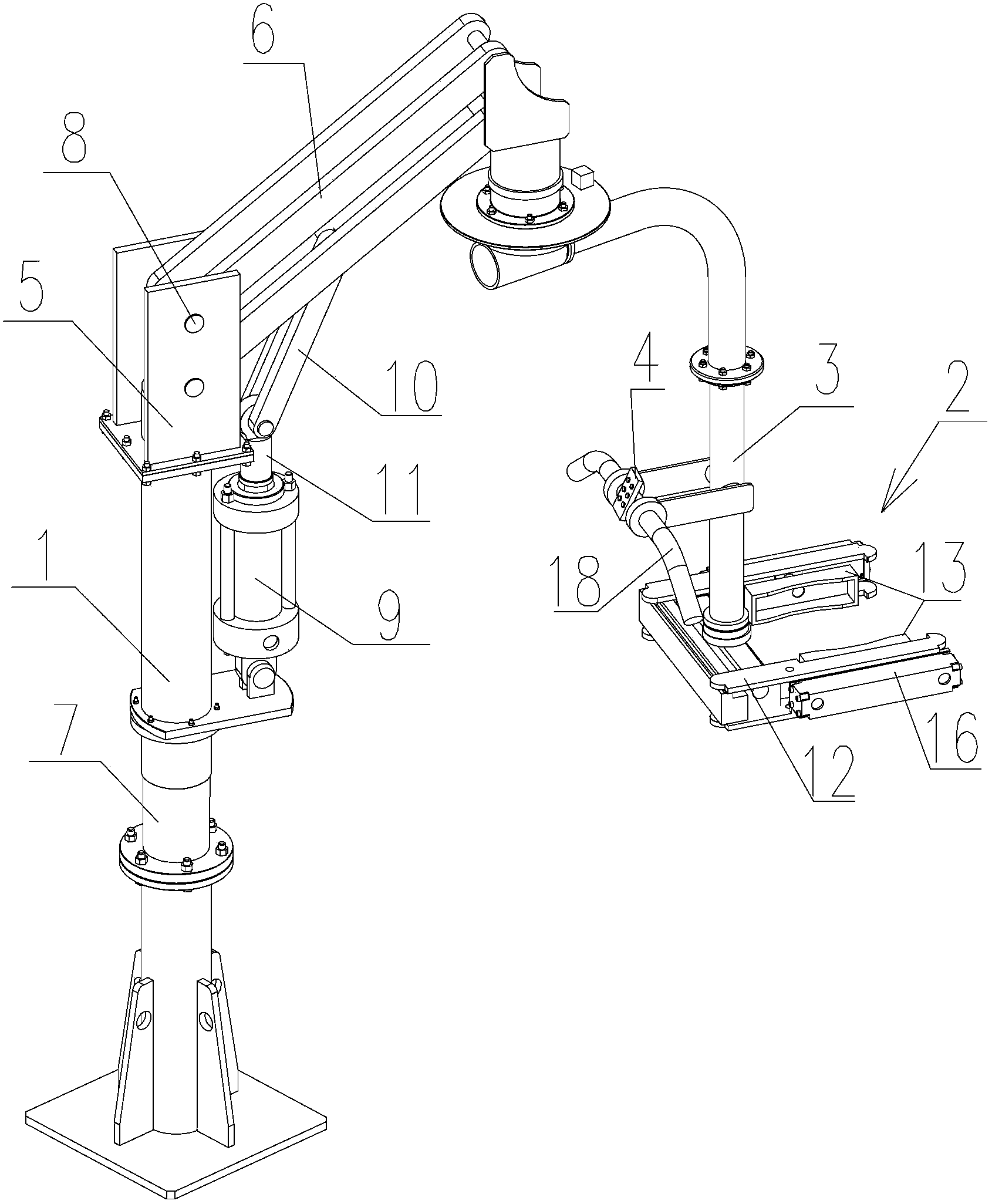

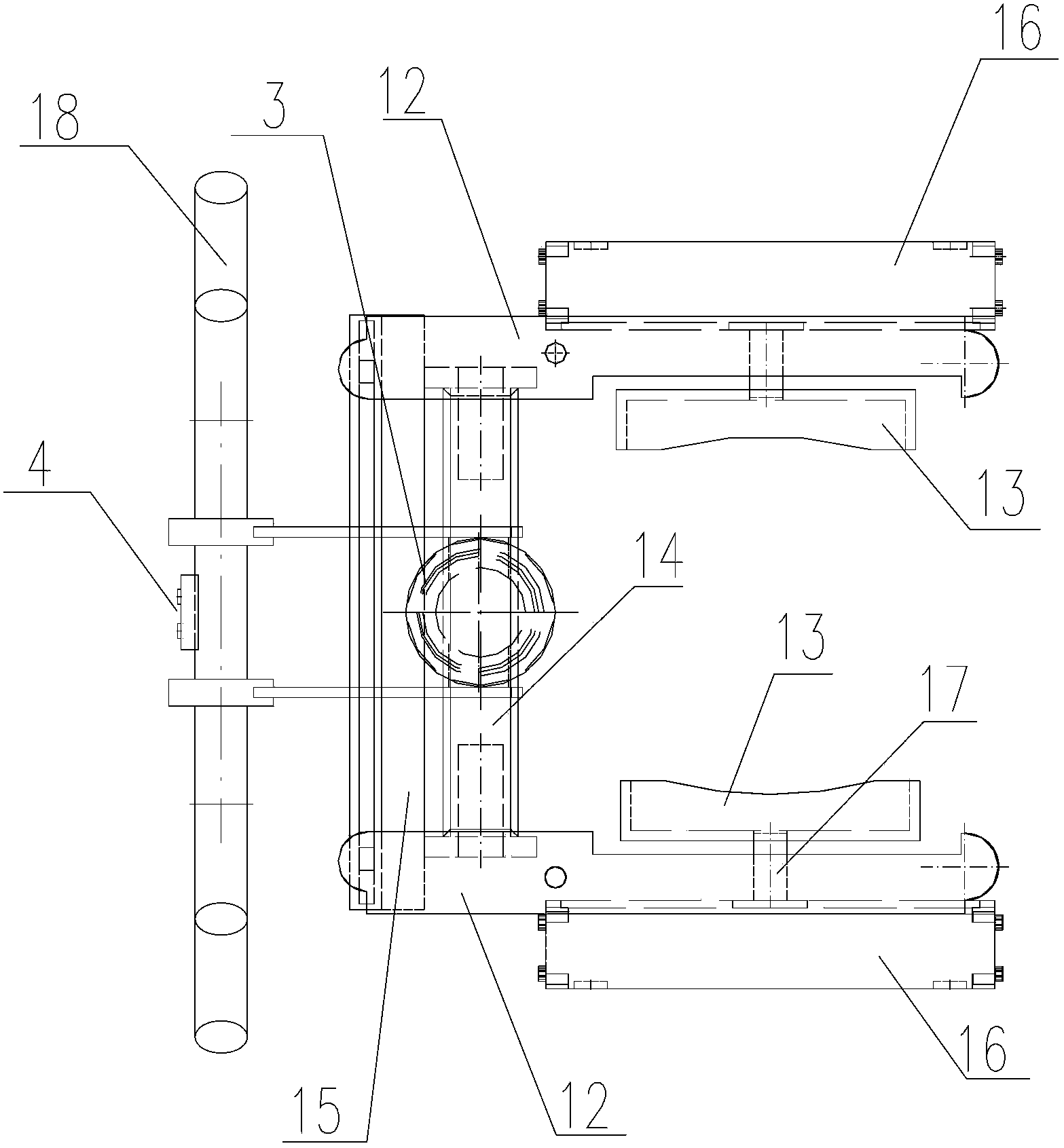

[0020] Such as figure 1 As shown, a multi-degree-of-freedom manipulator clamp includes a manipulator main body 1, a clamping mechanism 2, a connecting arm 3 for connecting the manipulator main body 1 and the clamping mechanism 2, and a controller.

[0021] Among them, such as figure 1 As shown, the manipulator mainframe 1 includes a central rotary cantilever crane 5, the cantilever crane 5 is centered on a steel column 7, the column 7 is fixed on the floor of the workshop, the cantilever 6 rotates 360 degrees around the column 7, the cantilever 6 and the column 7 The top of the cantilever is connected by a pin 8, the cantilever 6 is lifted in the vertical direction by a telescopic cylinder 9, the telescopic cylinder 9 is fixed on the column 7, the cantilever 6 is connected to the telescopic rod 11 of the telescopic cylinder 9 through the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com