Method for controlling hump rolling and classification tail plane rolling sub-region operation of railway classification yard

The technology of hump slip and plane slip is applied in the field of operation control of hump slip and braided tail plane slip in railway marshalling yard, which can solve the problems of inability to realize automatic connection, low labor efficiency, hidden danger of iron shoes, etc. To achieve the effect of preventing vehicles from cross-regional conflict operations, improving labor efficiency, and saving personnel expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

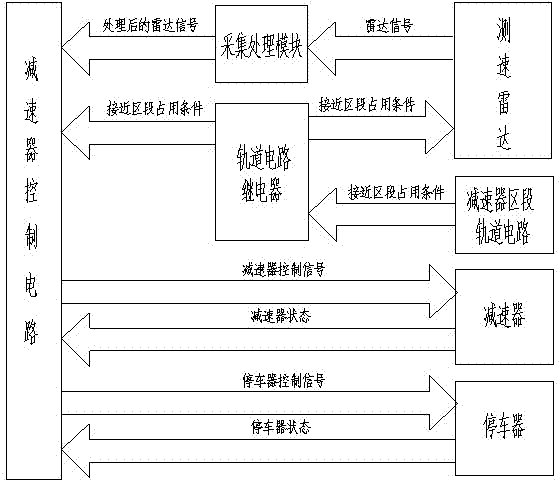

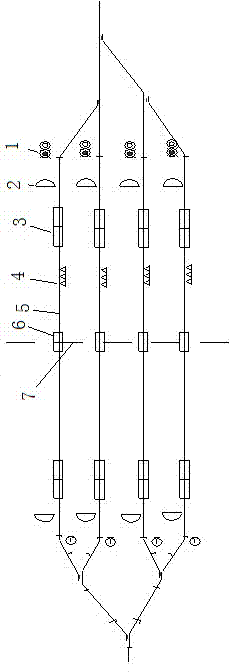

[0017] The method of the present invention is as follows: set a divisional operation demarcation point on the same track in the railway marshalling yard, set a parking device at the divisional operation demarcation point, and the plane sliding speed regulation area is formed between the weaving tail lead-out line and the divisional operation demarcation point, and the marshalling yard head The hump drop-off area is between the hump at the top and the dividing point of the divisional operation; a clamp-type reducer is set at the entrance of the tailing yard and 80 to 120m away from the shunting signal machine of the tailing yard, and in the target area of the reducer A deceleration roof is set at the slope change point section from the terminal to the tailing yard, and a speed measuring radar is set between the shunting signal machine and the clamp-type reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com