PVC (polyvinyl chloride) air blowing slipper and preparation method thereof

A technology for slippers and preparation steps, applied in the field of PVC air blowing slippers and preparation thereof, can solve the problems of easy burning, uneven foaming of cells, easy coking and discoloration of materials, etc., and achieves light soles, not easy to age, good softness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

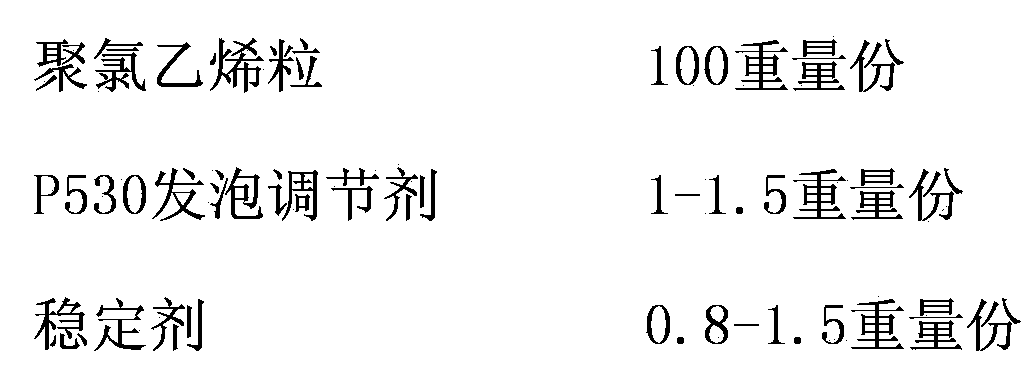

[0020] A kind of PVC blowing slippers is characterized in that, the composition of its sole molding raw material is:

[0021]

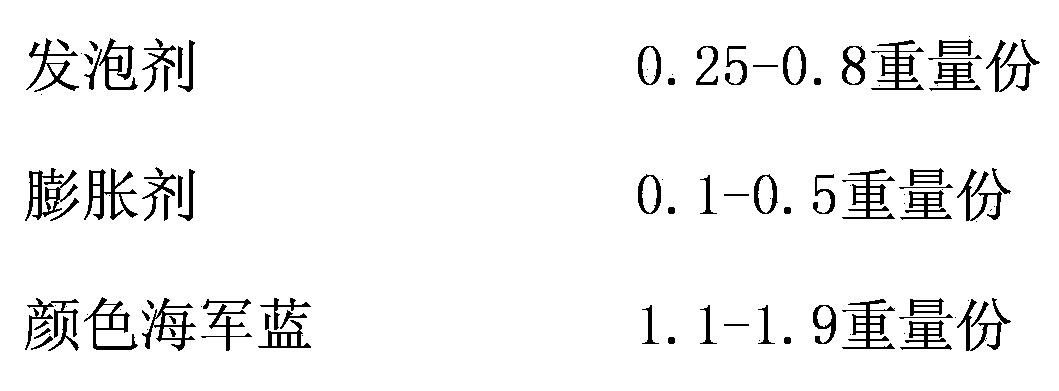

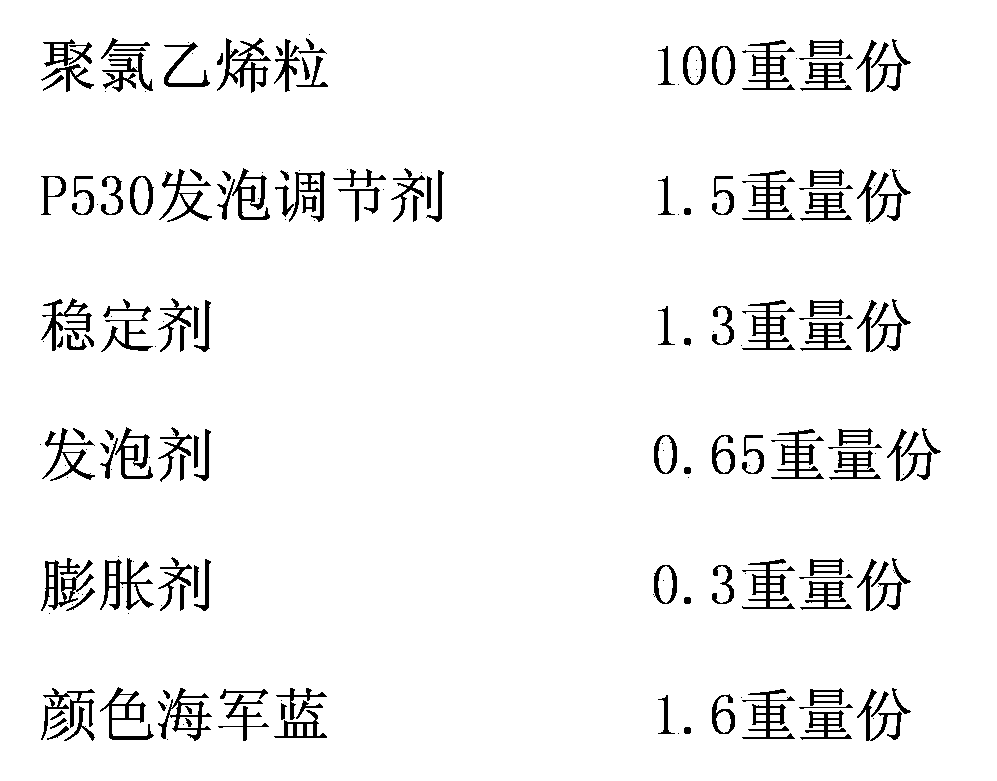

[0022] A kind of PVC blowing slippers, the composition of its sole forming raw material is preferably:

[0023]

[0024] A preparation method of PVC air-blown slippers, comprising the preparation step of PVC air-blown sole, is characterized in that, comprises the following steps:

[0025] Step 1, with 100 parts by weight of polyvinyl chloride particles, 1-1.5 parts by weight of P530 foam regulator, 0.8-1.5 parts by weight of stabilizer, 0.25-0.8 parts by weight of foaming agent, 0.1-0.5 parts by weight of Swelling agent, 1.1-1.9 parts by weight of color navy blue are made into sole molding raw materials;

[0026] Step 2. Stir the above-mentioned sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com