New technology for processing thick-aroma tea oil

A new technology, tea oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of limited application range, deep color, low nutritional value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

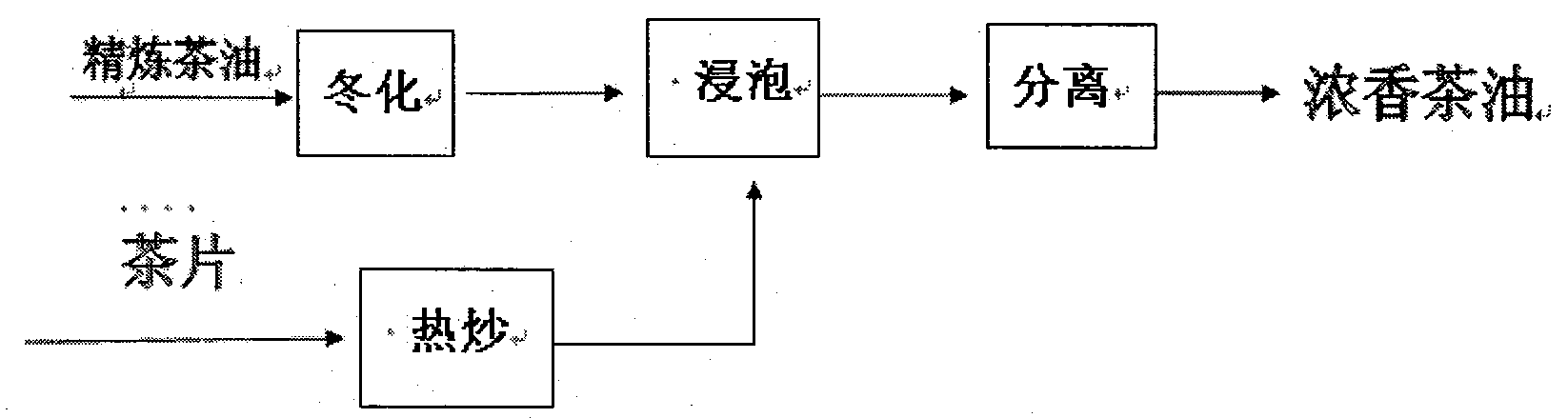

Method used

Image

Examples

Embodiment example 1

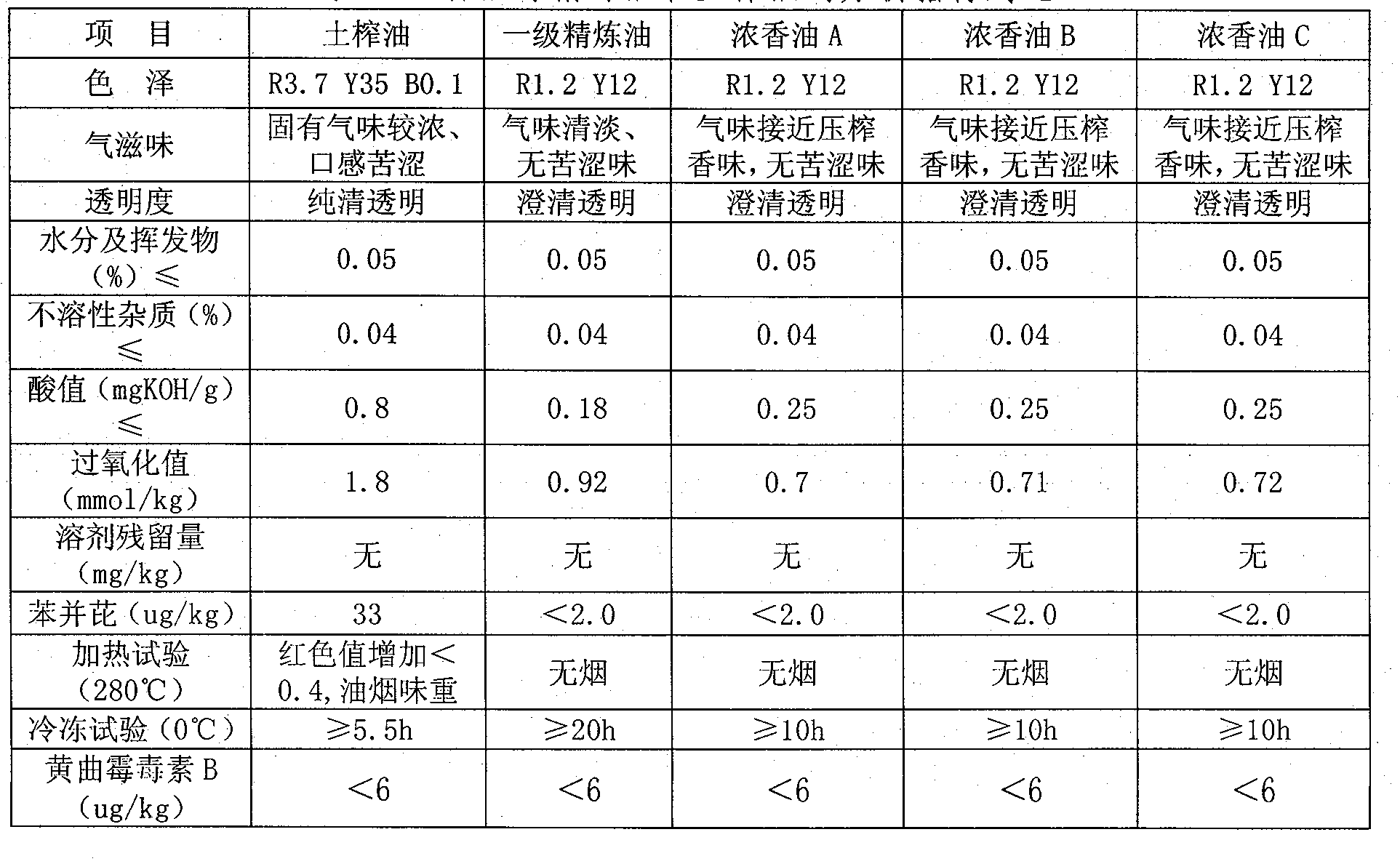

[0010] Take 10 tons of refined tea oil, put it into the winterization tank with a pump, lower the temperature from normal temperature to 3°C, keep it warm at 3°C, and hold it for 90 hours, filter to obtain degreased refined tea oil, and heat it up to 60°C; take fresh camellia oleifera seeds 3 tons of tea flakes that came out during the oil extraction process were stir-fried in a wok at 70°C for 2 hours, then winterized tea oil and fried tea flakes were put into the extractor together, soaked for 8 hours, and the oil and The tea flakes are separated to obtain Luzhou-flavored tea oil A.

Embodiment example 2

[0012] Take 5 tons of refined tea oil, put it into the winterization tank with a pump, lower the temperature from normal temperature to 2°C, keep it at 2°C for 80 hours, filter to obtain degreased refined tea oil, and heat it up to 60°C; take fresh camellia oleifera seeds 3 tons of tea seed shells that come out of the shelling and oil extraction process are stir-fried in a wok at 80°C for 2 hours, and then the winterized tea oil and fried tea seed shells are put into the extractor together, soaked for 10 hours , separating the oil from the tea husk to obtain the aromatic tea oil B.

Embodiment example 3

[0014] Take 8 tons of refined tea oil, put it into the winterization tank with a pump, lower the temperature from normal temperature to 1°C, keep it warm at 2°C, and hold it for 90 hours, filter to obtain degreased refined tea oil, and heat it up to 60°C; take fresh camellia oleifera seeds 5 tons of tea chips, the by-products of the oil extraction process, were stir-fried in a frying pan at 80°C for 2 hours, and then the winterized tea oil and fried tea chips were put into the extractor, soaked for 12 hours, and the oil Separated from the tea flakes to obtain the strong fragrance tea oil C.

[0015] The present invention obtains A, B, and C three kinds of strong-flavored camellia oils by changing different process conditions, and its analysis indexes are shown in Table 1. From Table 1, it can be clearly seen that each index is close to the index of refined oil, reaching the national consumption Oil standard, but at the same time retains the unique fragrance of camellia oil. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com