Metal acid pickling corrosion inhibitor as well as preparation method and application thereof

A technology of pickling corrosion inhibitor and corrosion inhibitor, which is applied in the field of metal pickling corrosion and protection, can solve the problems of large influence of acidity of pickling solution and low corrosion inhibition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation process of the pickling corrosion inhibitor is as follows.

[0043] Add 1.72g of L-cysteine methyl ester hydrochloride, 20-30mL of dichloromethane and 1.4mL of triethylamine in sequence to a 100mL three-necked flask, stir at room temperature for 10-15min, then dropwise add 2.2g of di-tert-dicarbonate Butyl ester (its structural formula is (Boc) 2 0), after the dropwise addition, continue to stir at room temperature for 30-40min, add 20-25mL water to the mixed solution, separate the liquids, wash the organic phase with water, dry over anhydrous magnesium sulfate, and rotary evaporate the solvent dichloromethane to obtain the Boc protected amino group L-cysteine methyl ester Me 3 COOCNHCH(COOMe)CH 2 SH.

[0044] In a 100mL round bottom flask, add 2.37g Me 3 COOCNHCH(COOMe)CH 2 SH, 2.64g nickel complex Ni(dppe)Cl 2 , 30-40mL tetrahydrofuran, 1.4mL triethylamine. After stirring and reacting at room temperature for 1-1.2h, the reaction solvent was ...

Embodiment 1

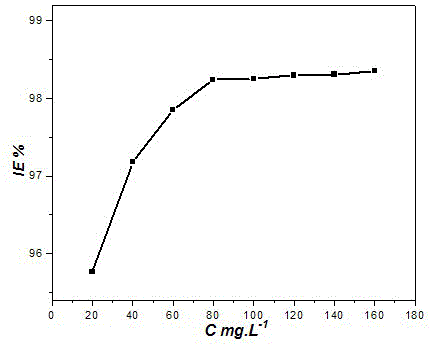

[0045] Example 1 This example is the influence of different concentrations of pickling corrosion inhibitors of the present invention on the corrosion inhibition rate of HCl pickling solution

[0046] In order to investigate the relationship between the concentration of the pickling corrosion inhibitor of the present invention and the corrosion inhibition rate of the HCl pickling solution, in this embodiment, the pickling corrosion inhibitor is added under the same HCl concentration (1mol / L, molar concentration, the same below). , so that the concentration of pickling corrosion inhibitor is 20-160mg / L. Under the temperature condition of 30 ℃, it was used for pickling of Q235 steel, and the corrosion inhibition rate of various pickling solutions was measured. The results are shown in Table 1. And take the concentration C (mg / L) of the pickling corrosion inhibitor as the abscissa, and the corrosion inhibition rate IE (%) as the ordinate, obtain the concentration of the pickling c...

Embodiment 2

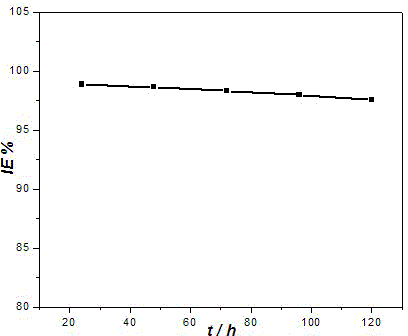

[0050] Embodiment 2 This embodiment is the effect of action time on the corrosion inhibition rate of HCl pickling solution

[0051] In order to investigate the relationship between the action time and the corrosion inhibition rate of the HCl pickling solution, in this example, the pickling corrosion inhibitor prepared above was added to the same concentration of HCl solution (1mol / L) at the same concentration (80mg / L). Under the conditions of 30°C temperature and different action time, it was used for pickling of Q235 steel, and the corrosion inhibition rate of the pickling solution was measured at different times. The results are shown in Table 2. And take time (t) as the abscissa, and the corrosion inhibition rate IE (%) as the ordinate, to obtain the relationship diagram between time and corrosion inhibition rate, as figure 2 shown.

[0052] Table 2 Effect of time on corrosion inhibition rate of HCl pickling solution

[0053] time (t, h)

[0054] According to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com