A light-duty well point downpipe hole-forming device and method thereof

A light-duty well point and hole-forming device technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of slow hole-forming and complicated operation, and achieve the effects of convenient use, low price and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

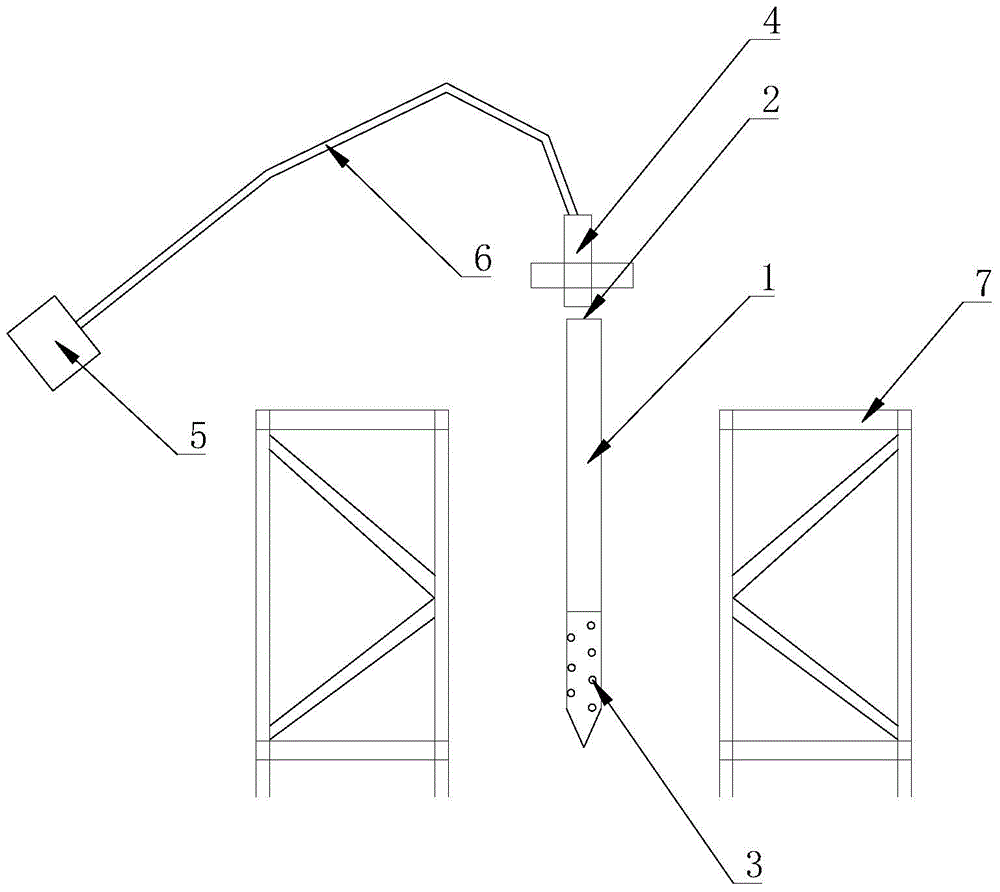

[0018] Such as figure 1 As shown, the light well point dewatering pipe hole forming device according to the embodiment of the present invention includes a downpipe 1 and a hammer sinking device used in conjunction with it. The top of the downpipe 1 is provided with an opening 2 and the lower part of the downpipe 1 is distributed The permeable hole 3, the bottom end of the downpipe 1 is a closed end; the hammer sinking device includes a hammer 4 and an air compressor 5, and a pressure hose 6 is connected between the air compressor 5 and the hammer 4 The permeable holes 3 are distributed in a plum blossom shape; the closed end of the bottom end of the downpipe 1 is conical.

[0019] The method for forming a hole for a light well point dewatering pipe according to an embodiment of the present invention includes the following steps:

[0020] 1) Prepare the downpipe according to the engineering requirements: about 6m in length, 48.3mm in diameter, 3.5mm wall thickness, 0.7m in the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com