Rotary-cutting type pipeline cleaner

A pipe dredge and rotary cutting technology, which is applied in the field of pipeline dredging propulsion devices, can solve problems such as low efficiency, low efficiency, and high cost, and achieve the effects of convenient use, simple structure, and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

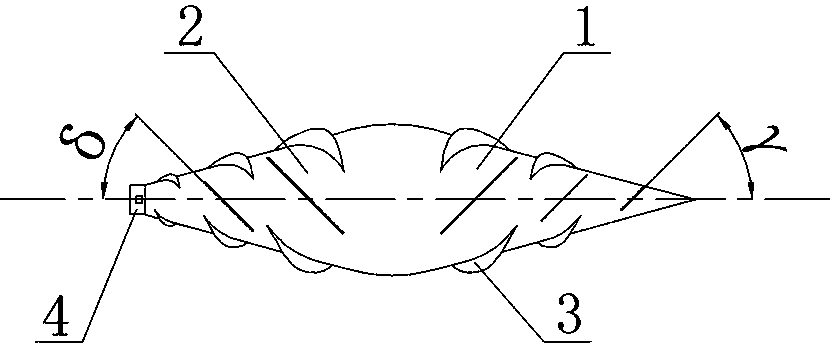

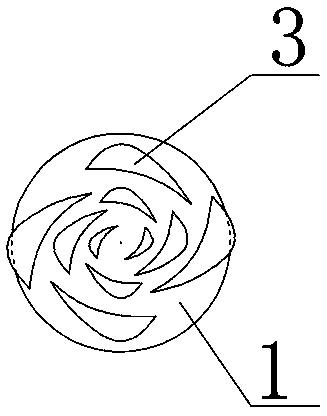

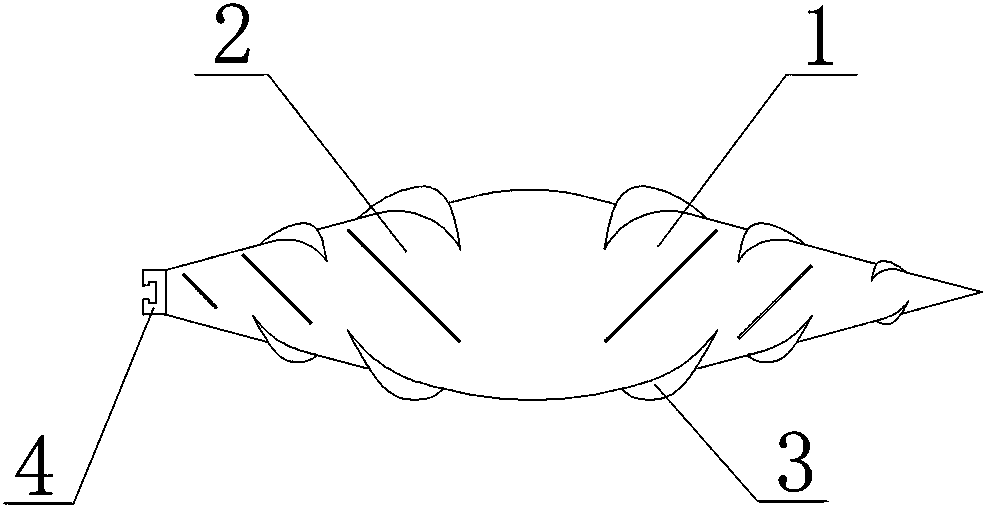

[0030] see Figure 1 to Figure 9 , a rotary-cutting type pipeline dredger of the present invention, comprising a shuttle-shaped dredge body, a rotary-cut blade 3 arranged outside the dredge body and a quick joint base at the bottom of the dredge, the rotary-cut blade 3 It includes a cutting part and a connecting part 303 matched and fixed with the dredge body. The cutting part includes a main cutting edge 301 and an auxiliary cutting edge 302. The two vertices of the connecting part of the rotary cutting blade 3 and the highest point of the cutting part relative to the connecting part form an included angle β It is an obtuse triangle of 125°~135°, and the angle α formed by the obtuse triangle relative to the side of the main cutting edge 301 and the side where the two vertices of the connecting portion are located is 15°~20°. The dredger body is composed of a conical advancing section 1 and an inverted conical exiting section 2. The rotary cutting blades 3 arranged on the adva...

Embodiment 2

[0034] The structure of embodiment two is basically the same as that of embodiment one, and the similarities will not be repeated. The difference is that the number of rotary cutting blades 3 on the advancing section 1 and the exiting section 2 is 12, and the rotary cutting blades 3 are 12. The cutting blades 3 are arranged in four rows on the outer surfaces of the advancing section 1 and the exiting section 2, and the four-row rotary cutting blades 3 have three single rows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com