Prefabricated assembled type steel structure house building system and construction method thereof

A prefabricated assembly and steel structure technology, applied in the direction of building structure, construction, building components, etc., to achieve the effect of convenient transportation, high degree of industrialization, and reduction of on-site operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

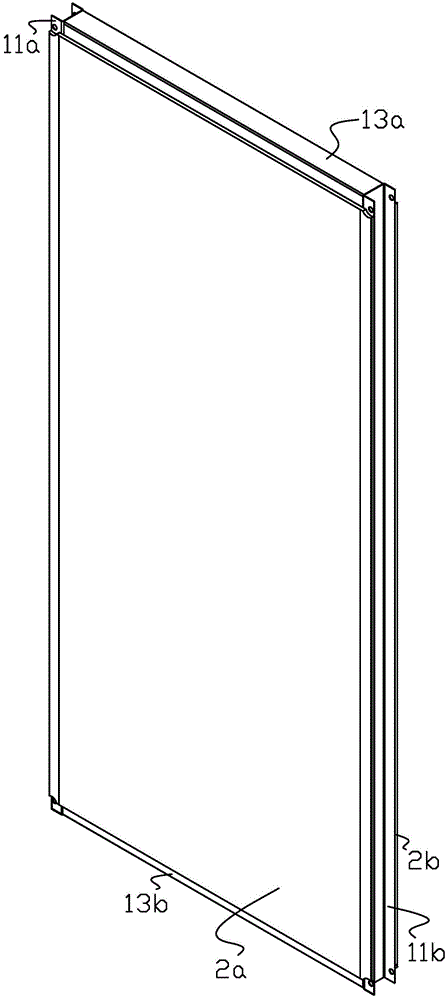

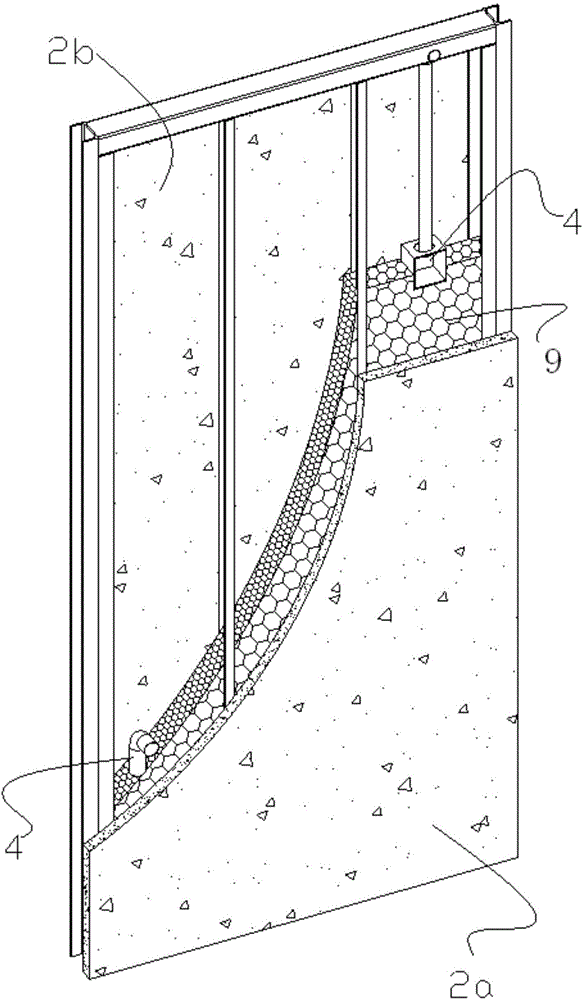

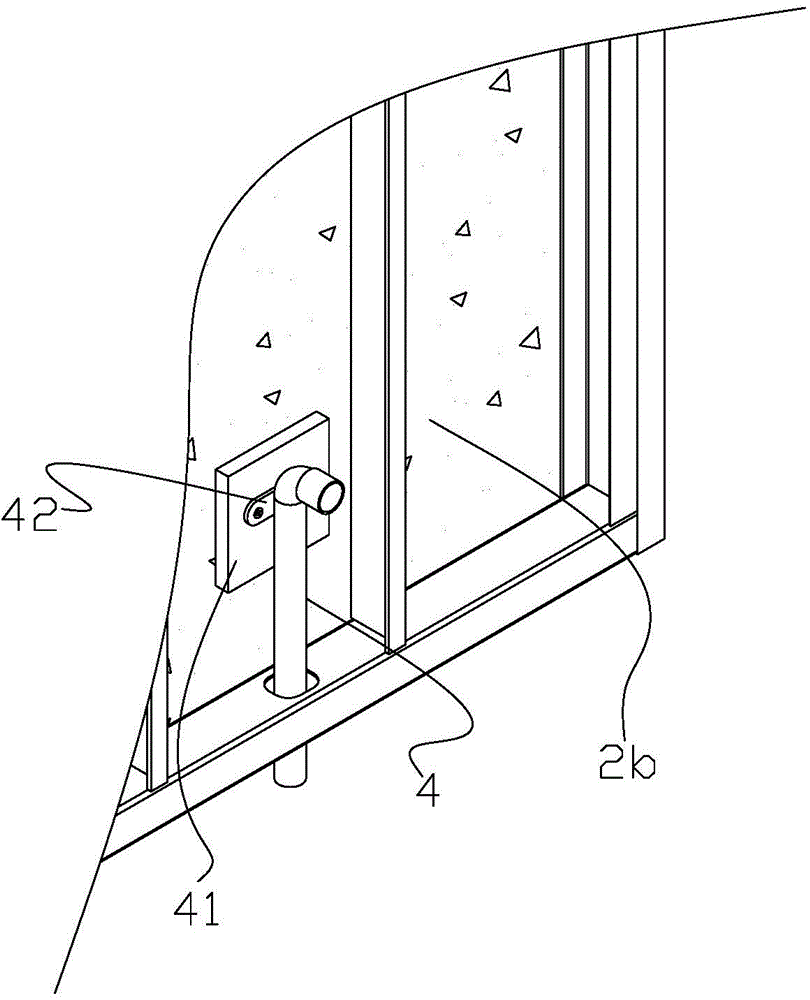

[0045] Such as Figures 1 to 8 As shown, the prefabricated panel structure of the present invention can refer to the Chinese patent document whose publication number is CN 103015623 A, but because the prefabricated panel of the present invention generally includes wall prefabricated panels used as walls, windows with windows installed according to the architectural pattern body prefabricated panel and the door body prefabricated panel installed with the door body, therefore, the prefabricated panel of the present invention carries out corresponding deformation on the basis of the prefabricated panel disclosed in the above patent documents, which is reflected in: as Figures 1 to 8 As shown, the prefabricated panel of the present invention includes a light steel frame 1 and front and rear plates 2a, 2b, and the light steel frame 1 includes surrounding together (the light steel frame 1 of the present invention can be completely assembled by self-tapping screws) to form a side Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com