Device and method for inhibiting vortex-induced vibration of spiral strake with rotating blade

A technology of spiral strakes and suppression devices, which is applied in earthwork drilling, fluid flow, and reduction of ship motion, can solve the problems of vortex-induced vibration suppression effect to be further improved, increase riser drag force, etc., and achieve the best suppression effect , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

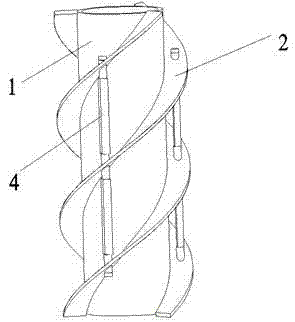

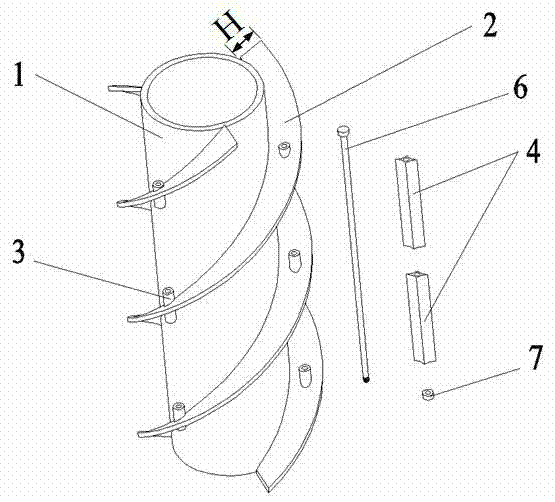

[0026] According to the slenderness ratio of the actual marine riser and the perennial statistical information of local ocean waves and currents, a reasonable basic unit spacing is designed, and the required number of basic units n is calculated, that is, the sleeve with the spiral strake 2 and the support 3 The number of 1 is n, the number of 4 blades is 6n, the number of 6 screws and 7 nuts is 3n.

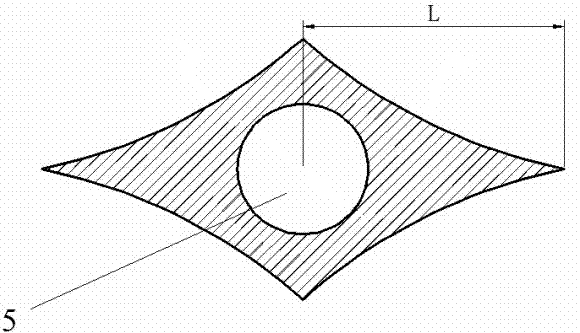

[0027] When installing a single basic unit, first set the sleeve 1 and fix it at a suitable position on the standpipe, then take two blades 4 and place them between the supports 3 on the same vertical line, and make the blade shaft holes 5 and the supports The shaft holes of 3 are aligned, and the screw rod 6 passes through the shaft holes of the three supports 3 on the vertical line and the blade shaft holes 5 of the two blades 4 between the three supports 3 from top to bottom, and the screw thread at one end of the screw rod 6 It is fixed by the engagement of nut 7. So far, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com