Sealing Mechanism for Rotary Handling Devices

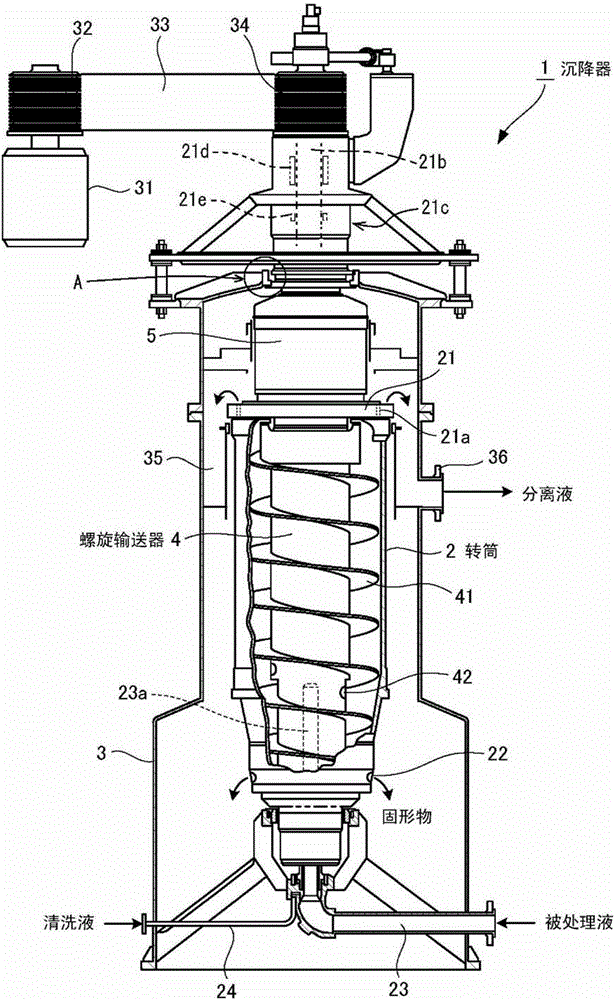

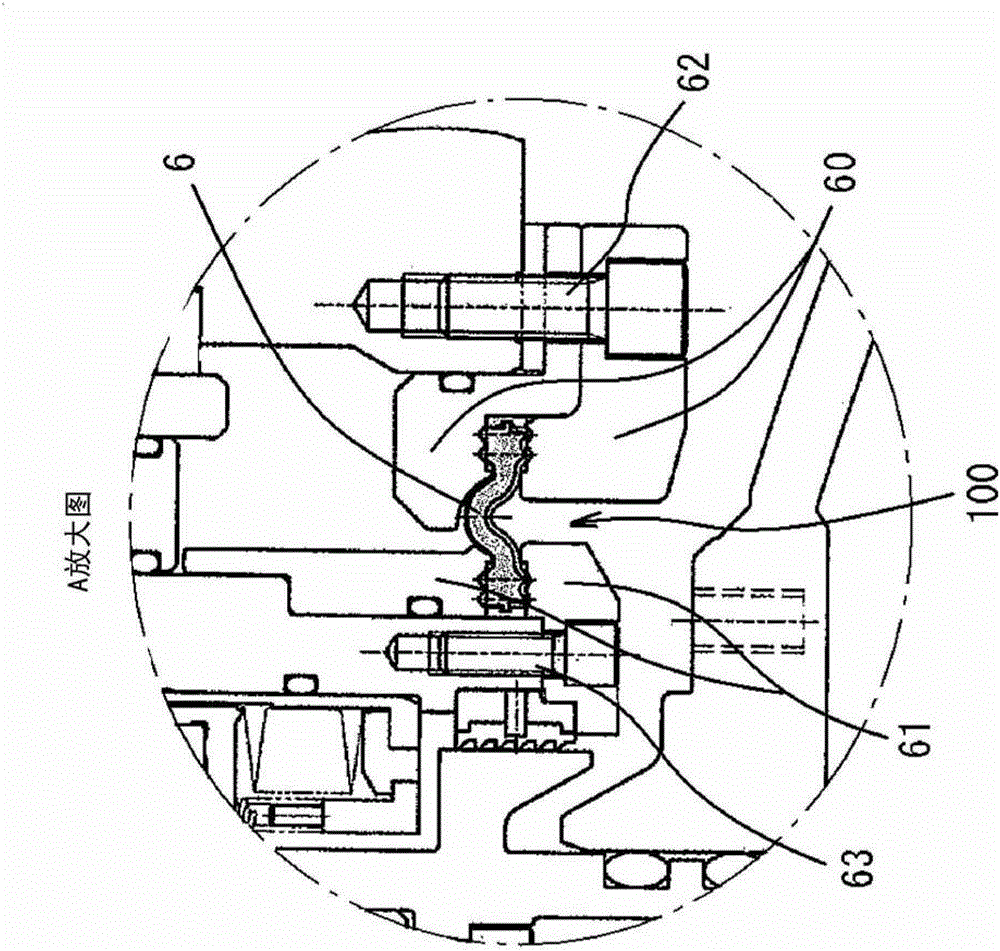

A technology of rotating processing devices and sealing components, which is applied to centrifuges with rotating drums, engine seals, centrifuges, etc., can solve problems such as loose sealing characteristics, insufficient sealing characteristics, and poor pressure resistance, and achieve suppression Reduced sealing properties, suppression of leakage of contents, and reduction in diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Next, examples performed to confirm the effects of the present invention will be described.

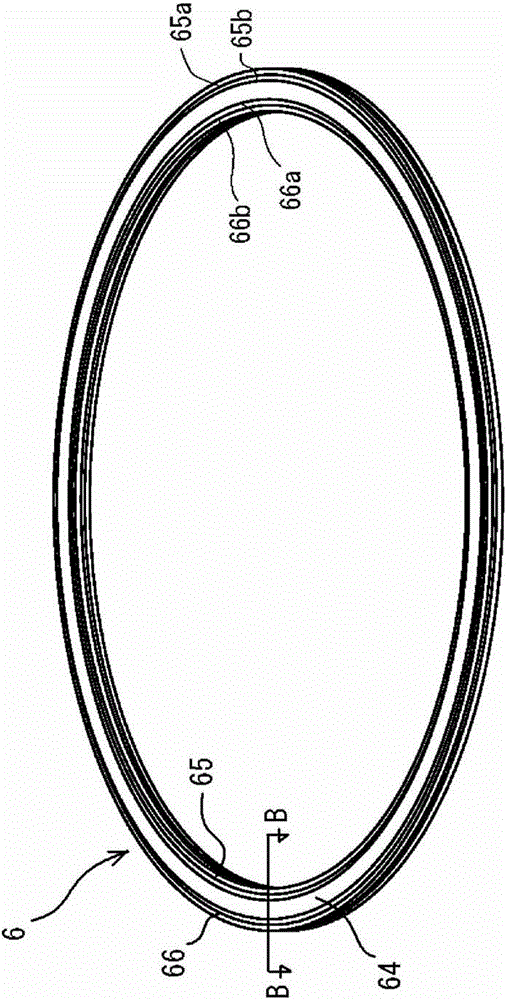

[0048] Such as Figure 6 As shown, in addition to confirming the sealing member 6 (a) of the above-mentioned embodiment, the present inventors also confirmed that there are two peaks (b) only on the upper surface, one peak (c) on the upper and lower sides, and two peaks (c) on the lower surface only. Sealing properties of a peak (d) and a sealing member without a convex portion (e). Figure 6 The results are shown together.

[0049] For the reasons already described, the sealing member of (a) has good sealing properties based on the contact area (sealing properties: ○), and leakage due to positional displacement due to vibration or the like does not occur (stability: ○). On the other hand, when there is one peak (c) up and down, the sealing property is good (◯), but leakage due to positional displacement was confirmed (stability: x). In addition, the flat seal member (e) wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com