Backlight module

A technology of backlight module and light source, applied in the field of direct type backlight module, can solve the problems of unevenness, MURA backlight module brightness, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

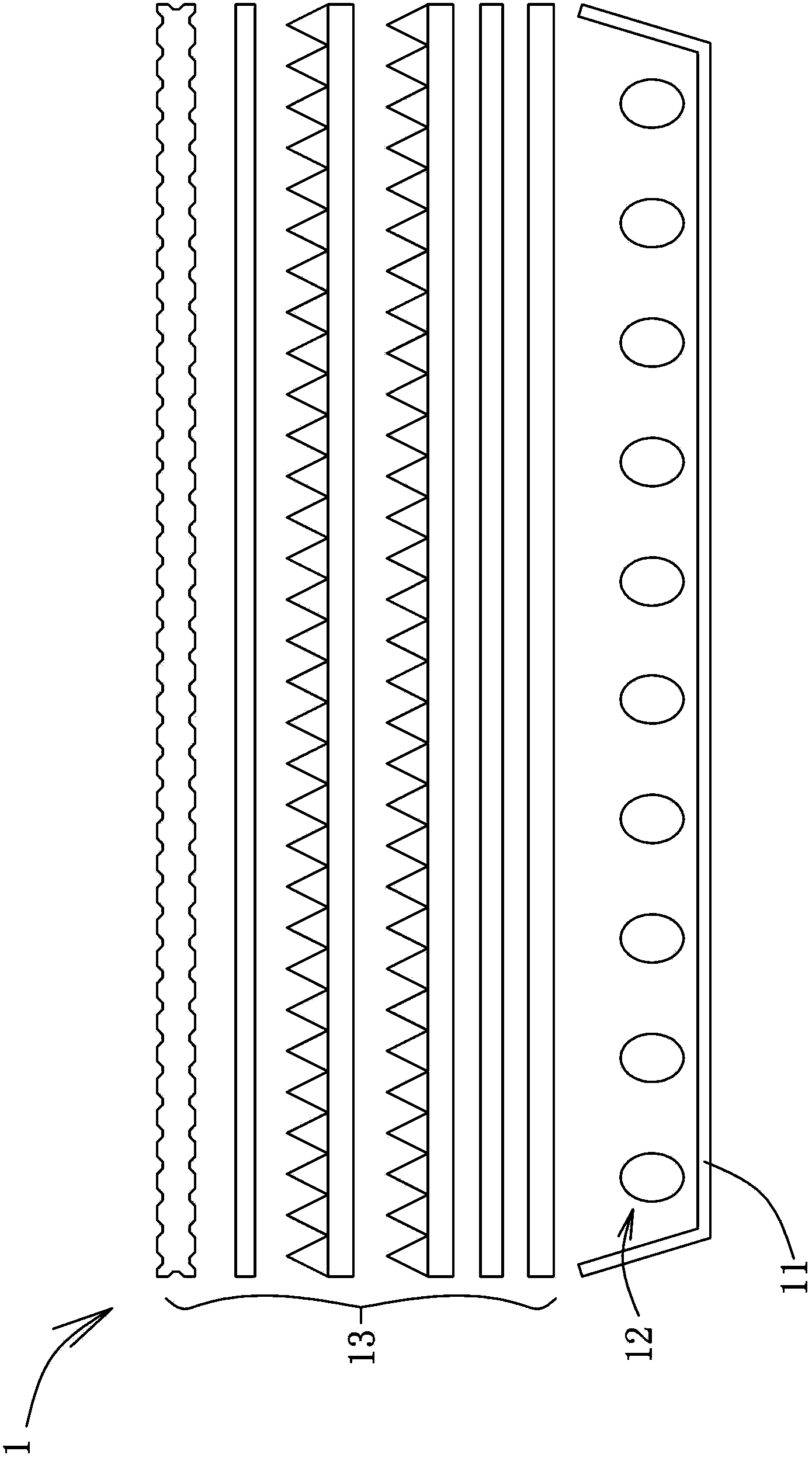

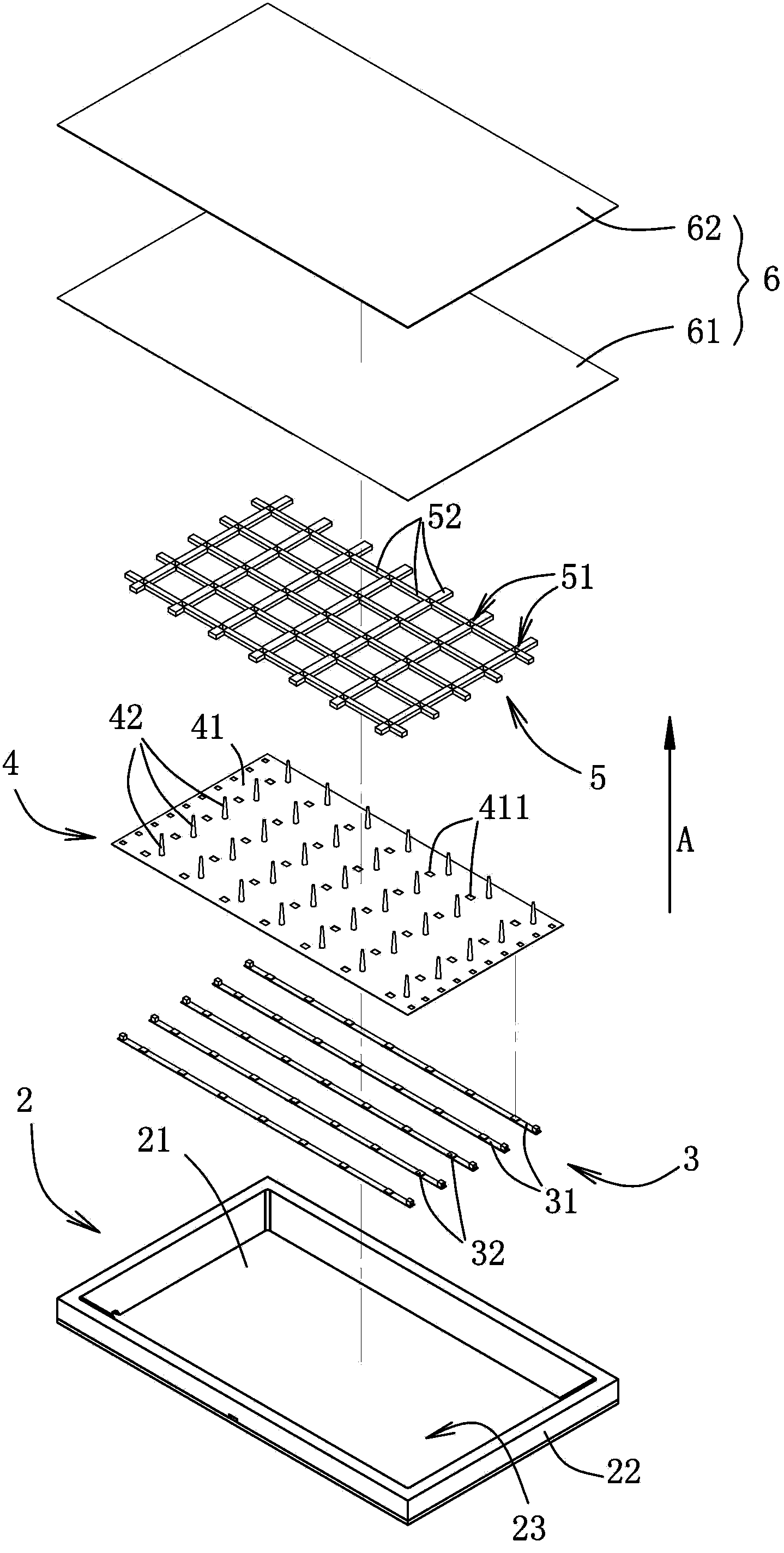

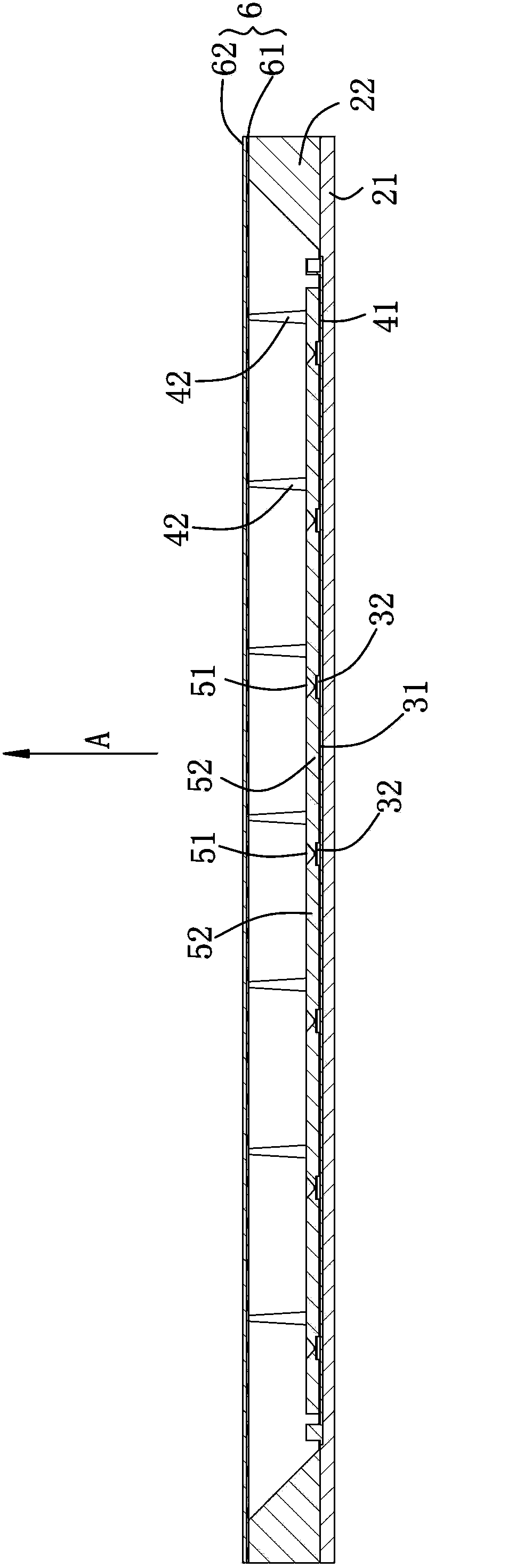

[0027] refer to figure 2 and image 3 , the first preferred embodiment of the backlight module of the present invention includes a casing 2 , a light source 3 , a supporting unit 4 , a secondary optical component 5 and an optical film set 6 .

[0028] The housing 2 has a base wall 21 , a surrounding wall 22 extending from the base wall 21 toward a first direction A, and an accommodating space 23 defined by the base wall 21 and the surrounding wall 22 . And the accommodating space 23 is for accommodating the light source 3 , the supporting unit 4 , the secondary optical component 5 and the optical film group 6 along the first direction A in sequence.

[0029] The light source 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com