Burning loss prevention method and device for turbulent burner

A technology of a swirl burner and a prevention method, which is applied to the combustion method, burner, burner for burning powder fuel, etc., can solve the burning loss of the swirl burner, and the safety and stable operation of a supercritical swirl combustion boiler. , power plant economic losses and other issues, to avoid serious economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

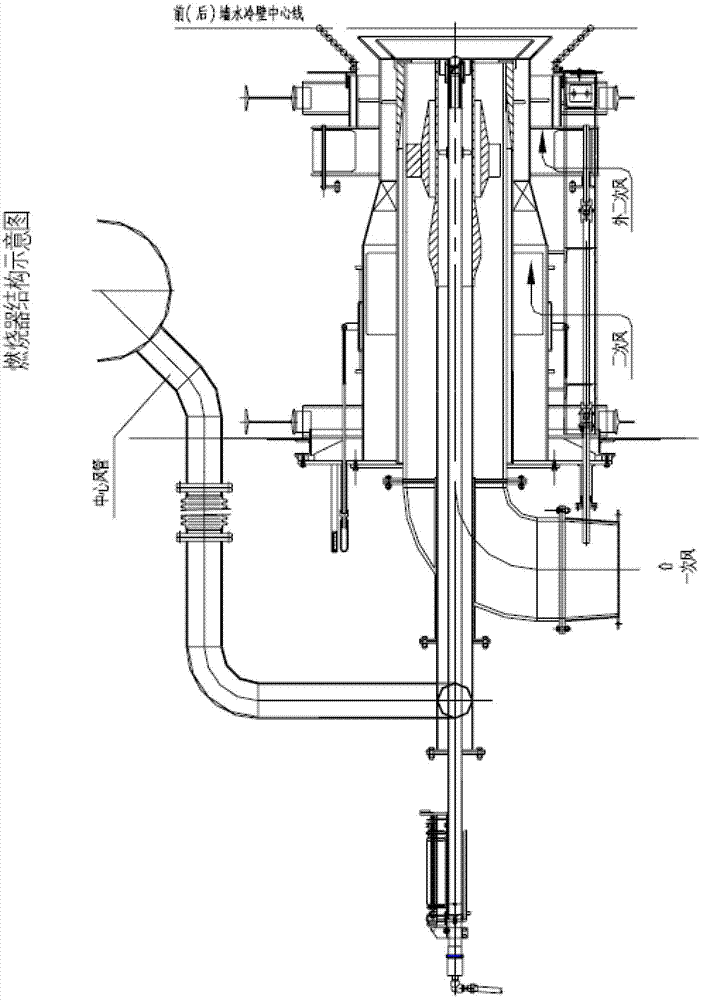

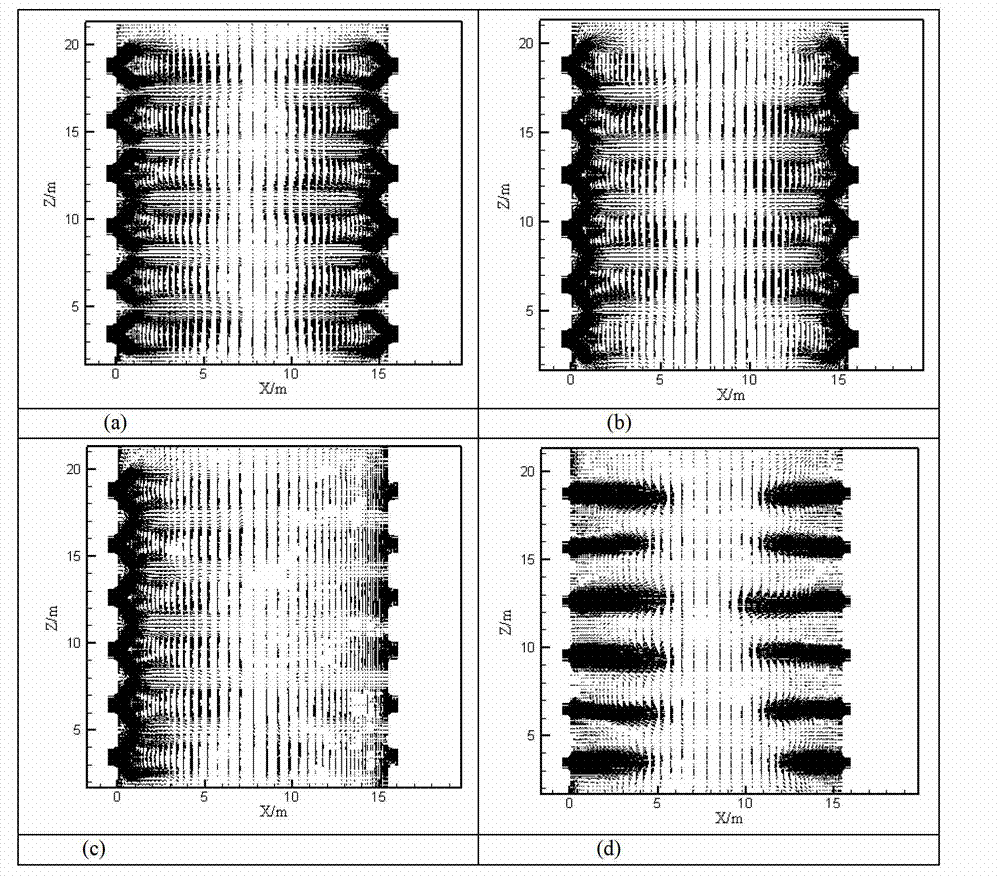

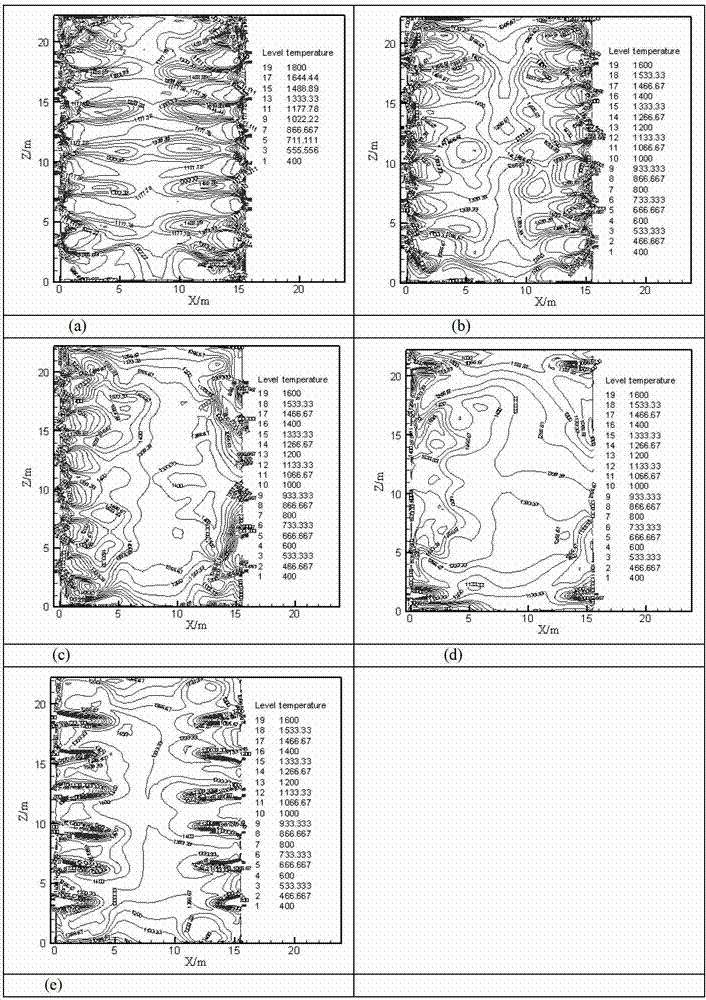

[0043] To prevent large-area burning of the swirl burner, it is first necessary to find out the cause of the burning. In order to analyze the cause of the large-area burning loss of the swirl burner as soon as possible, and propose burner modification measures and corresponding operation adjustment plans, the inventor conducted a detailed analysis of the cause of the swirl burner burning loss, through on-site inspection, laboratory Numerical simulation, on-site burner dynamic field test and other comprehensive technical means have fundamentally found the cause of the large-area burning loss of the swirl burner (DBC-OPCC), and proposed structural design, material selection, and on-site operation of the swirl burner. On the one hand, the transformation plan provides theoretical guidance for the safe operation of this type of swirl burner in the future, and has very important engineering significance for the safe and stable operation of the same type of swirl burner in the future....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com