Device for detecting coaxiality of main shaft hole and large oil seal hole of diesel engine block

A detection device and diesel engine technology, applied in the direction of mechanical measuring devices, measuring devices, mechanical devices, etc., can solve the problems of body surface pollution, lack of sealing effect, loss of engine oil, etc., to achieve flexible detection and adjustment, easy installation and Adjustable, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

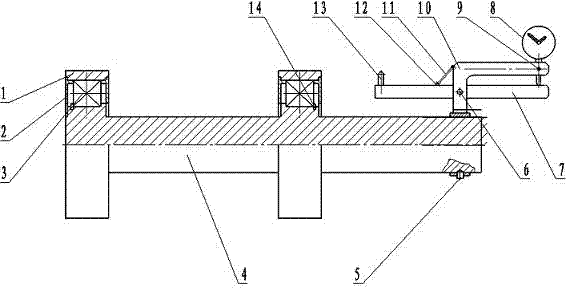

[0025] The embodiment that provides in conjunction with accompanying drawing illustrates structure of the present invention:

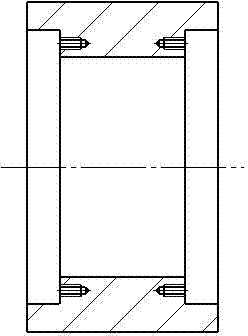

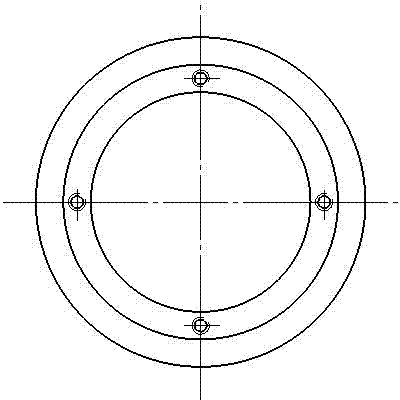

[0026] Such as figure 1 Shown, a kind of coaxiality detecting device of main shaft hole and big oil seal hole of diesel engine body, described coaxiality detecting device comprises mandrel 4 and lever type measuring mechanism; Figure 6 , the mandrel 4 is a rotary stepped shaft with two steps, the two steps are respectively located in the middle of the mandrel and one end of the mandrel, and the inner end faces of the two steps have ribs; The outer end surface of the step at one end of the mandrel has a slot for installing the bearing gland 2; the diameters of the two steps on the mandrel 4 are the same and are the maximum diameter of the mandrel; the two steps of the mandrel 4 The bearings 3 are all sleeved and the interference fit between the mandrel and the bearings; the mandrel outer ring 1 is sleeved outside the bearings 3; combined figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com