Railway vehicle braking cylinder piston assembly

A technology for railway vehicles and brake cylinders, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of affecting the braking performance of railway vehicles, straining the inner wall of the brake cylinder, and leakage of compressed air. Prevent the inner wall of the brake cylinder from being pulled, prolong the reliable use time, and prevent the effect of partial wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

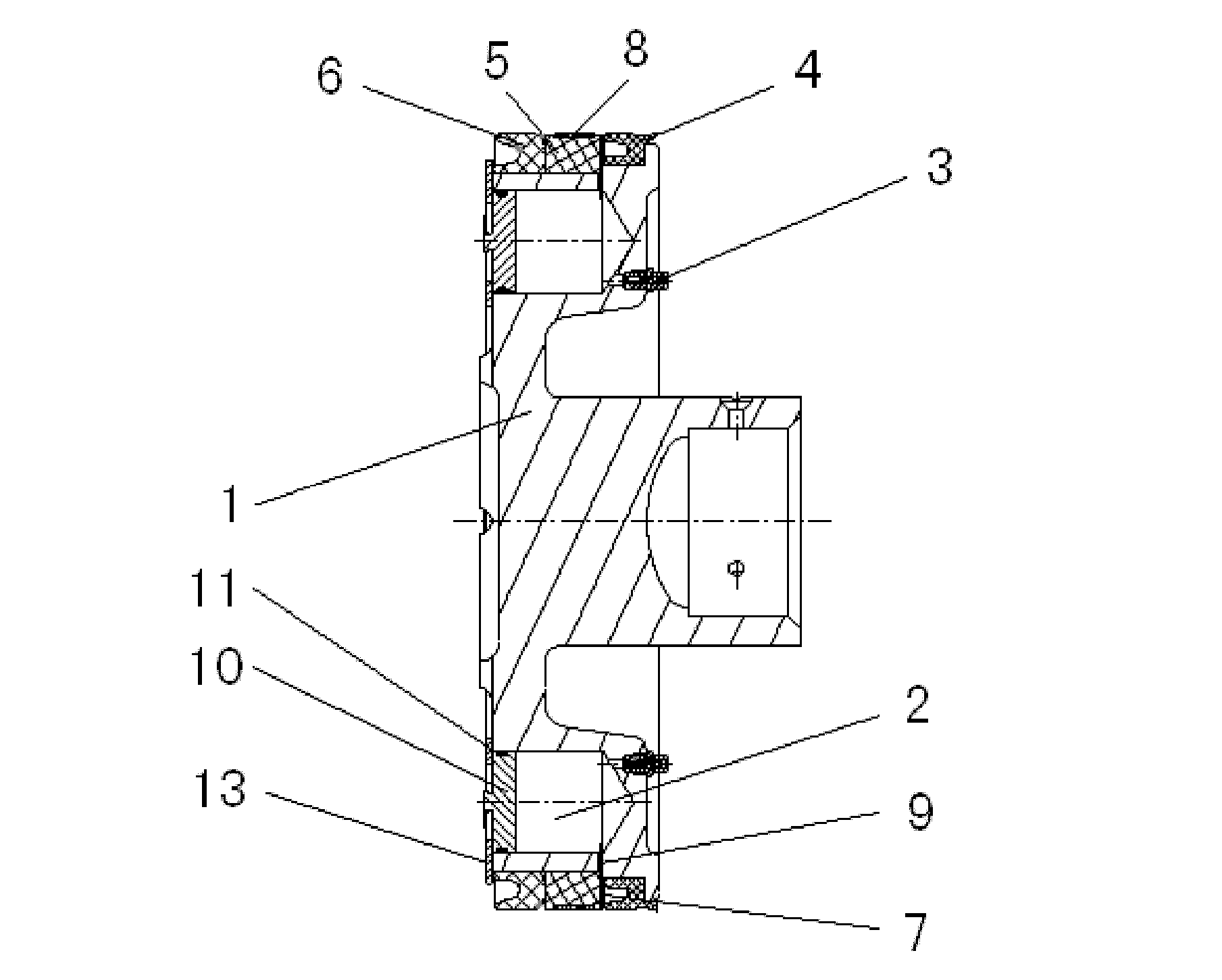

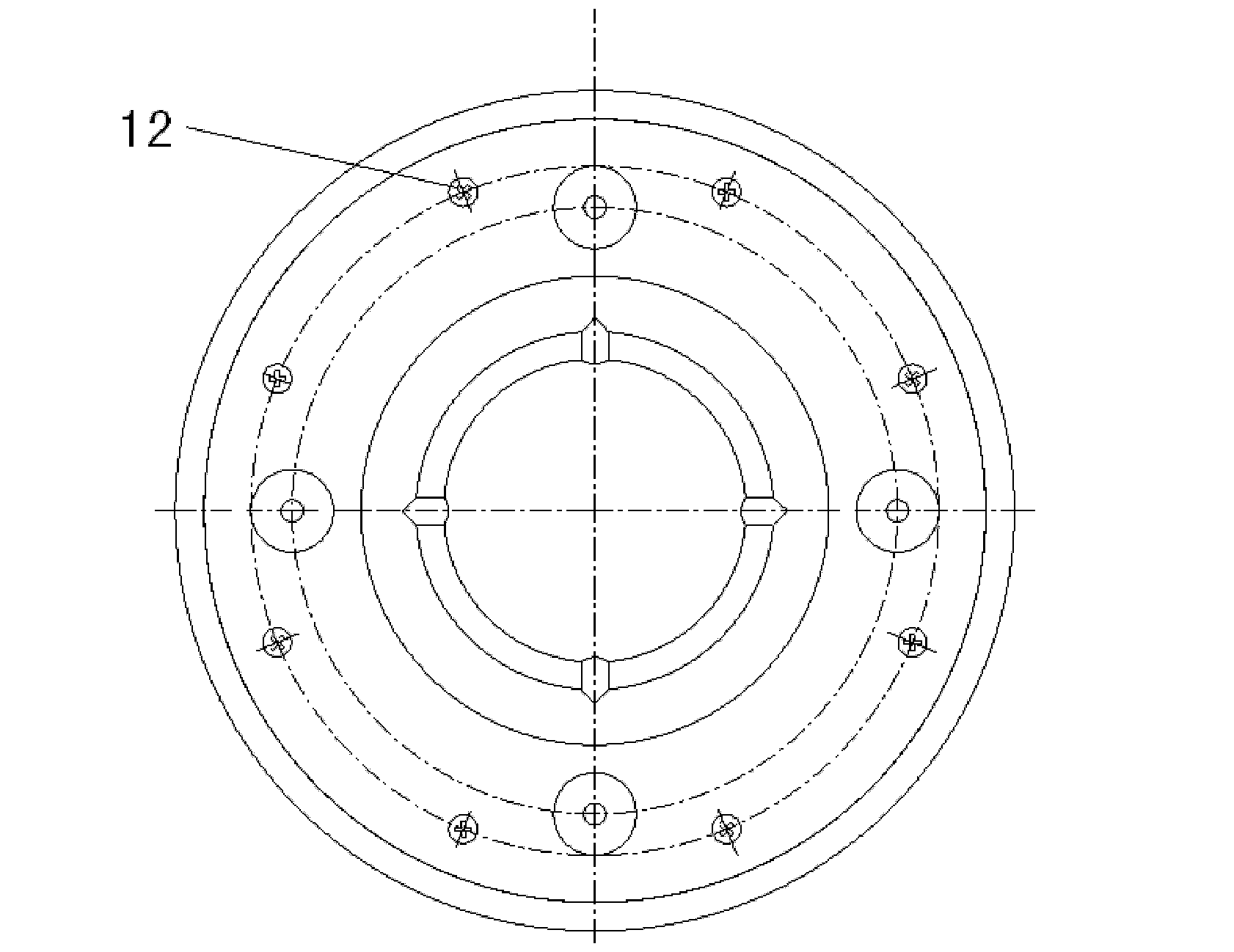

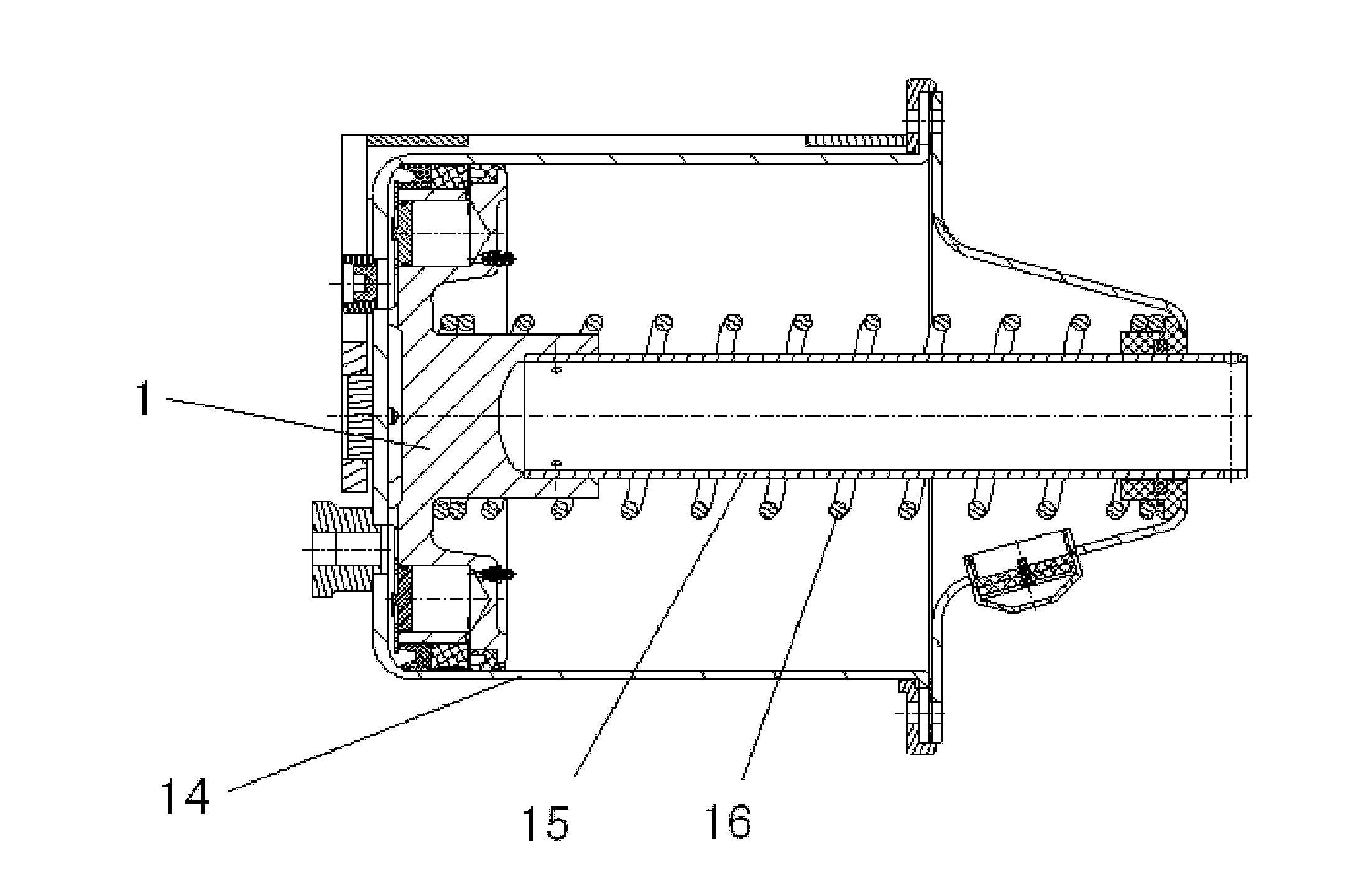

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] like figure 1 , figure 2 As shown, the present invention mainly adopts the grease retention technology, which includes a piston body 1, and 2 to 6 oil storage chambers 2 are arranged at intervals at the periphery of the piston body 1, and each oil storage chamber 2 and the inner side of the piston body 1 Each oil storage chamber 2 is respectively provided with a one-way passage oil cup 3, and the oil storage chamber 2 is replenished with grease through the oil cup 3. On the outer wall surface of the piston body 1, a rear seal ring 4, a spacer ring 5 and a front seal ring 6 are set sequentially from the inside to the outside. The inner diameter surface and both sides of the spacer ring 5 are provided with guides for circulating and distributing grease. The oil groove 7; the outside of the spacer ring 5 is also provided with a guide belt 8, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com