Method and device for aligning machine vision

A machine vision and alignment device technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of increased cost of machine vision alignment systems, algorithms affecting the real-time performance of visual alignment, and resolution that cannot meet requirements, etc. Achieve the effect of low cost, good real-time performance, and reduced data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to solve the problems of high cost and poor real-time performance of the current machine vision alignment method and its device, this embodiment provides a machine vision alignment method and its device. The machine vision alignment method and device thereof will be specifically described below in conjunction with specific embodiments.

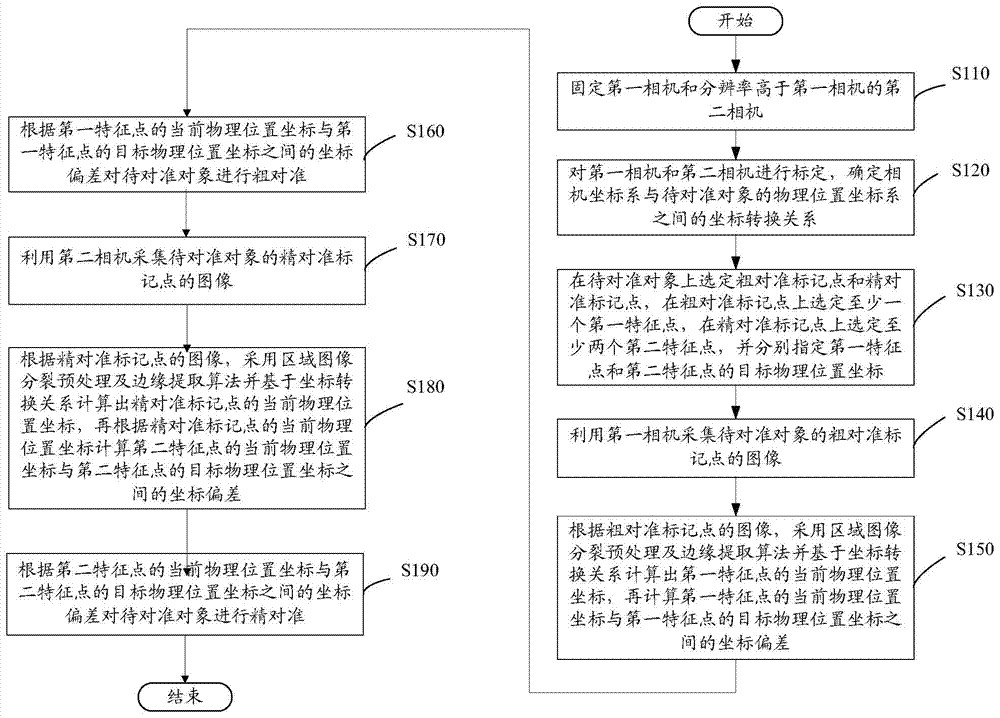

[0039] Please refer to figure 1 , the machine vision alignment method provided in this embodiment includes the following steps:

[0040] Step S110: Fixing the first camera and the second camera with higher resolution than the first camera. In this step, the positions of the first camera and the second camera are fixed, so that the first camera and the second camera can take pictures of the object to be aligned in the determined camera coordinate system. At the same time, the first camera and the second camera can be respectively fixed on two sides of the object to be aligned.

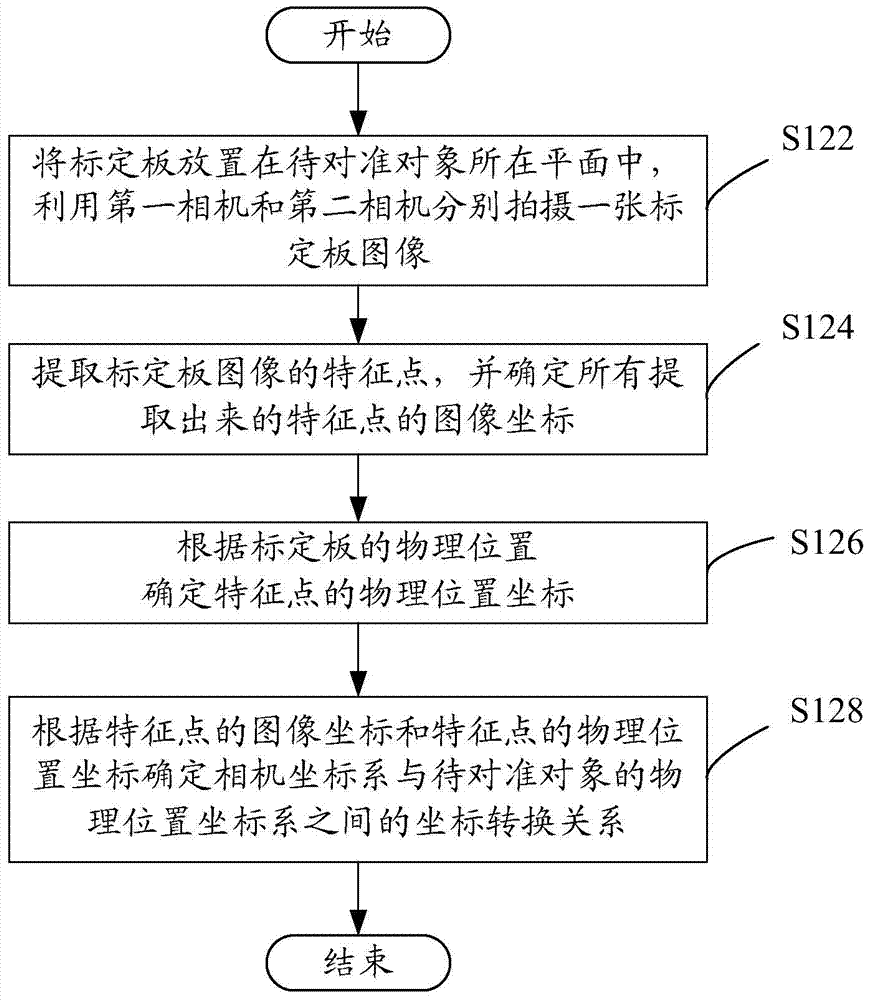

[0041] Step S120: Calibrate the first camera an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com