Trench IGBT and manufacturing method thereof

An insulated gate and channel technology, applied in the field of electronics, can solve the problems of accumulation layer channel type IGBT conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Compared with the existing Trench IGBT, the conduction voltage drop of the Trench IGBT provided by the invention is greatly reduced.

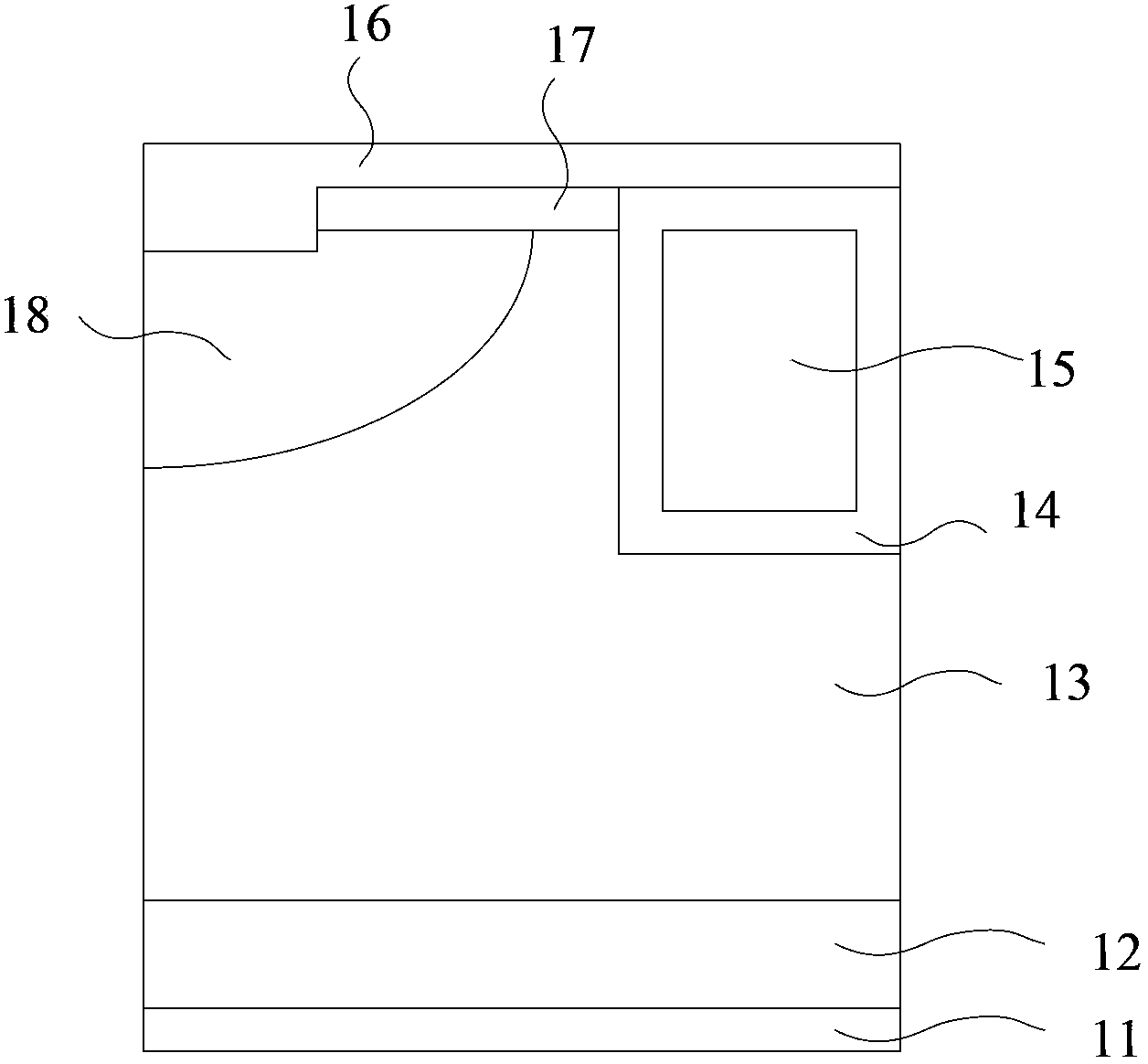

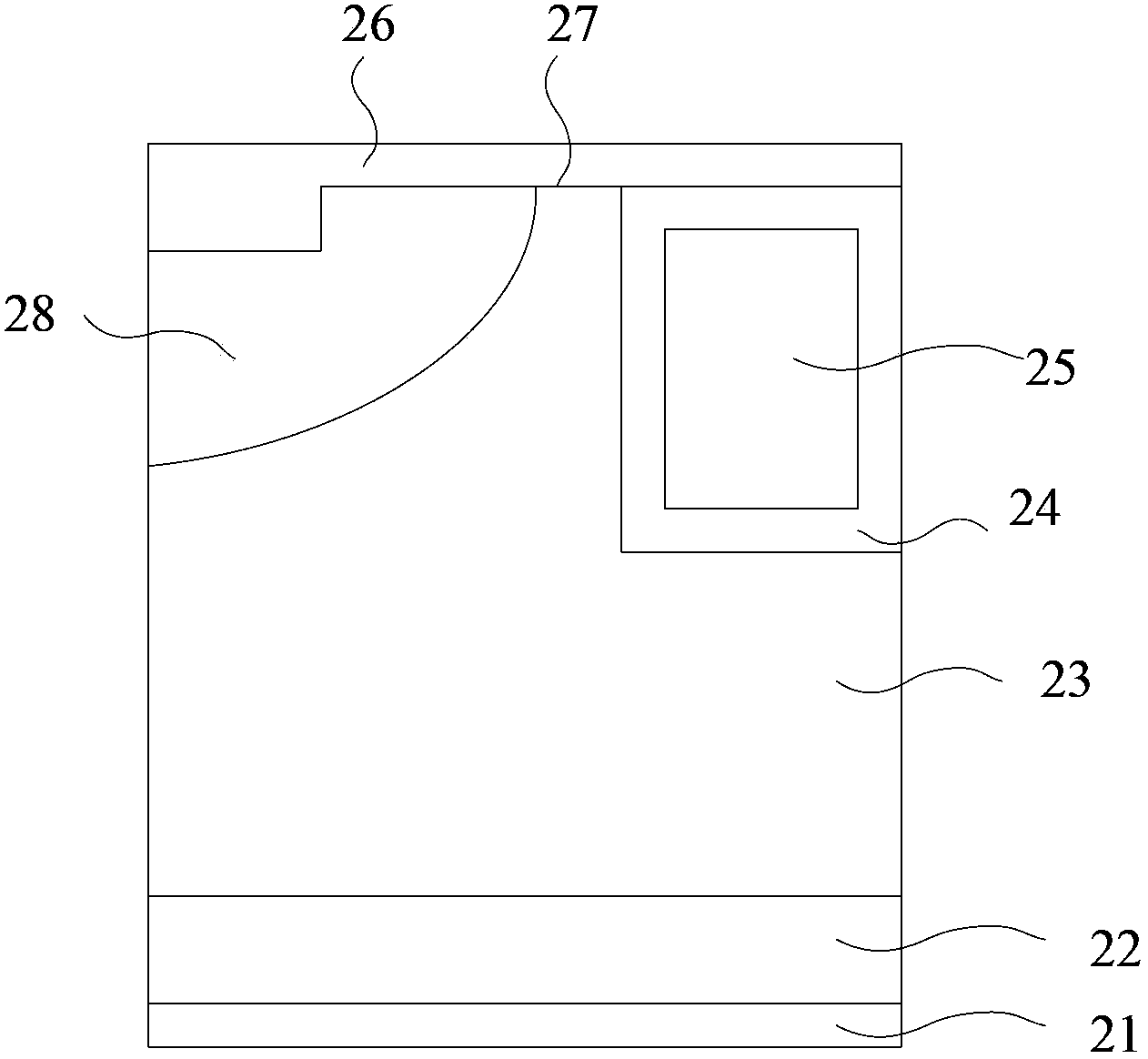

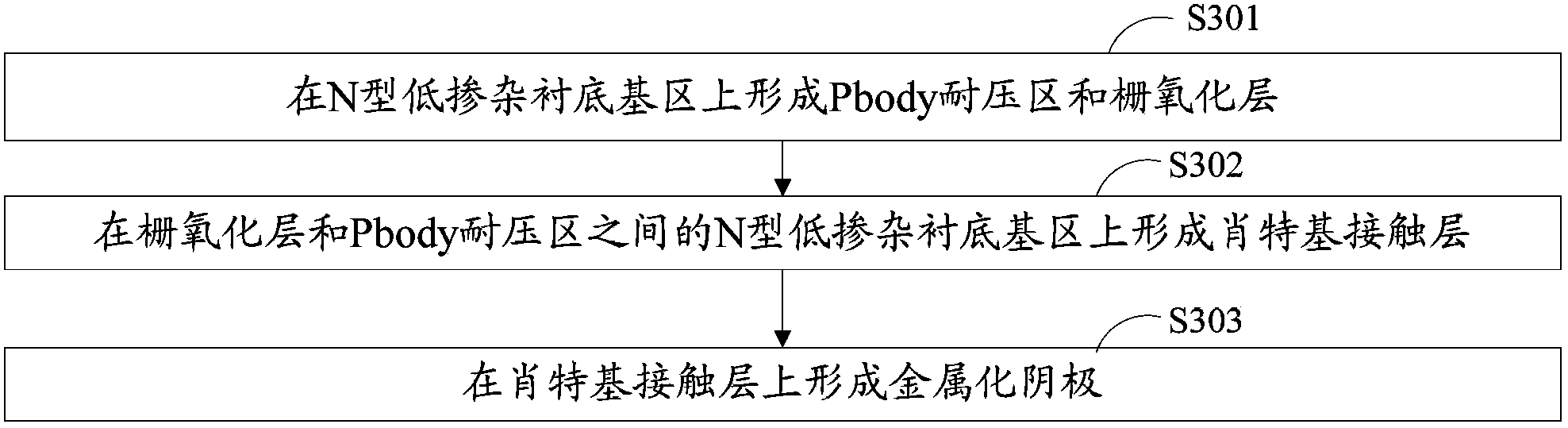

[0027] The Trench IGBT structure in the embodiment of the present invention will be described below with reference to the accompanying drawings. Such as figure 2 As shown, the Trench IGBT in this embodiment includes: a metalized anode 21, a P-type heavily doped region 22, an N-type low-doped substrate base region 23, a gate oxide layer 24, a gate electrode 25, a metalized cathode 26, Cathode metal Schottky contact layer 27 and Pbody withstand voltage region 28 .

[0028] Among them, the P-type heavily doped region 22 is in contact with the metallized anode 21, the N-type low-doped substrate base region 23 is in contact with the P-type heavily doped region 22, and the gate oxide layer 24 is in contact with the N-type low-doped substrate base region. 23, the gate electrode 25 is in contact with the gate oxide layer 24, the Pbody withsta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com