Method for manufacturing non-punch-through (NPT) type groove IGBT (Insulated Gate Bipolar Transistor) with field stop structure

A non-punch-through, manufacturing method technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult ohmic contact and large area, and achieve fast switching speed, excellent performance, and easy processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

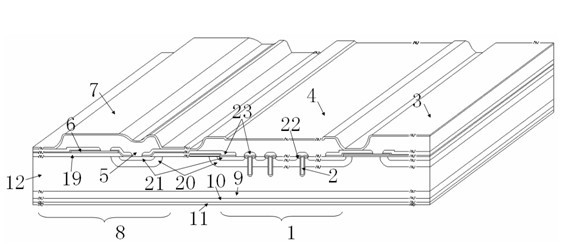

[0041] Below in conjunction with accompanying drawing, the present invention will be further described: with reference to Figure 1 to Figure 8 , the IGBT manufacturing method of the present invention has the following steps:

[0042] (1) Clean the silicon substrate, form a field silicon oxide insulating dielectric film 19 with a thickness of 1~2um on the upper surface of the silicon substrate through the first thermal oxidation growth, photolithography, and then etch the field silicon oxide The insulating dielectric film forms the cell region 1 and the voltage-resistant ring region 8, and forms one or more field-limiting ring injection regions 5 in the voltage-resistant ring region 8;

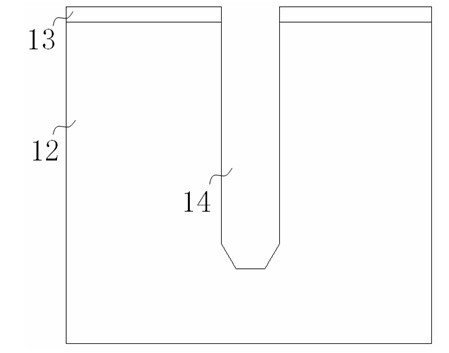

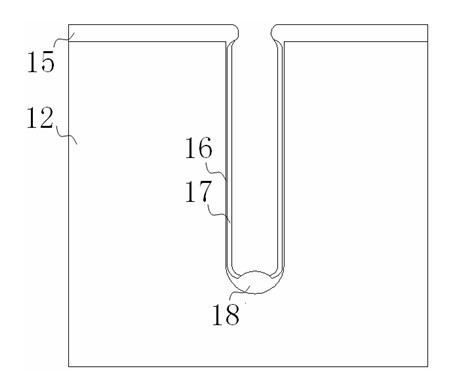

[0043] (2) Deposit a layer of silicon oxide insulating dielectric film 13 on the upper surface of the silicon substrate, remove the silicon oxide insulating dielectric film 13 at the position of the trench 14, and use the unetched silicon oxide insulating dielectric film 13 as a mask film etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com