Spring seat for push rod assembly of high pressure pump and high pressure pump

A spring seat, high pressure pump technology, applied in the direction of pumps, multi-cylinder pumps, fuel injection pumps, etc., can solve the problems of spring seat spring seat breakage, achieve uniform elastic deformation, and improve loading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

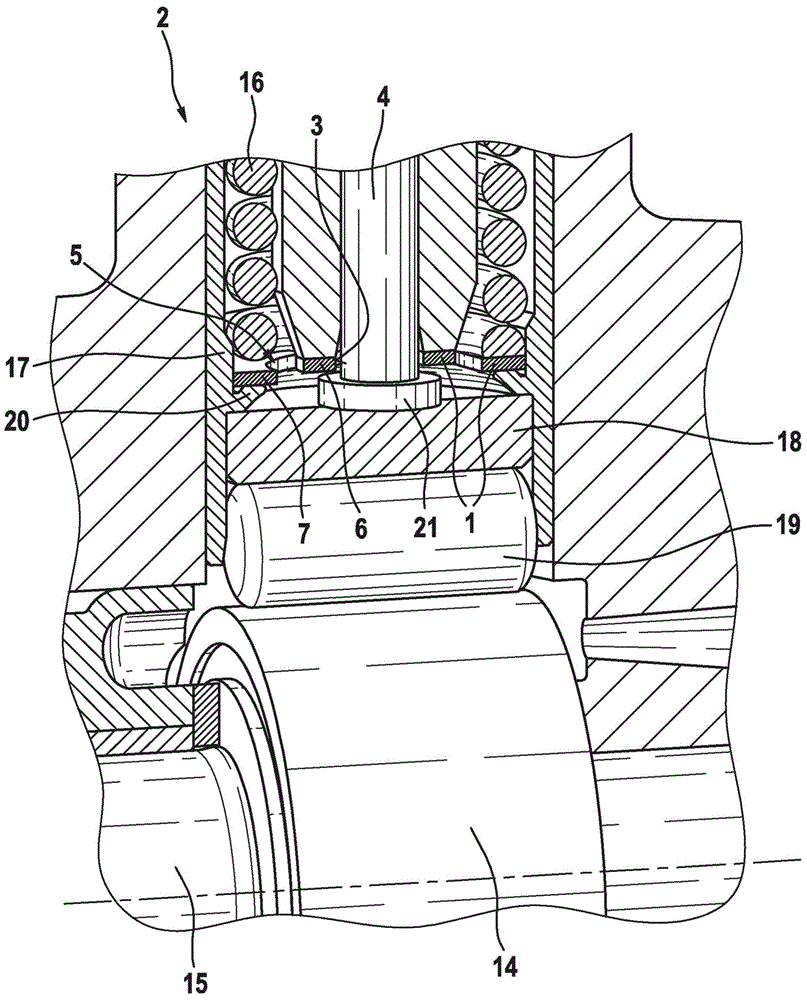

[0030] figure 1 The high-pressure pump according to the invention shown in the middle section comprises at least one pump part with a reciprocatingly guided pump piston 4 , which is supported via a push rod assembly 2 on a cam 14 of a drive shaft 15 . The push rod assembly 2 converts the rotational movement of the drive shaft 15 into a translational movement of the pump piston 4 . The push rod assembly 2 comprises a sleeve-shaped push rod body 17 and a support 18 accommodated therein, in which a roller 191 is rotatably mounted. The push rod assembly 2 abuts against the outer circumferential side of the cam 14 of the drive shaft 15 by means of a roller 19 . A return spring 16 keeps the push rod assembly 2 in contact with the cam 14 .

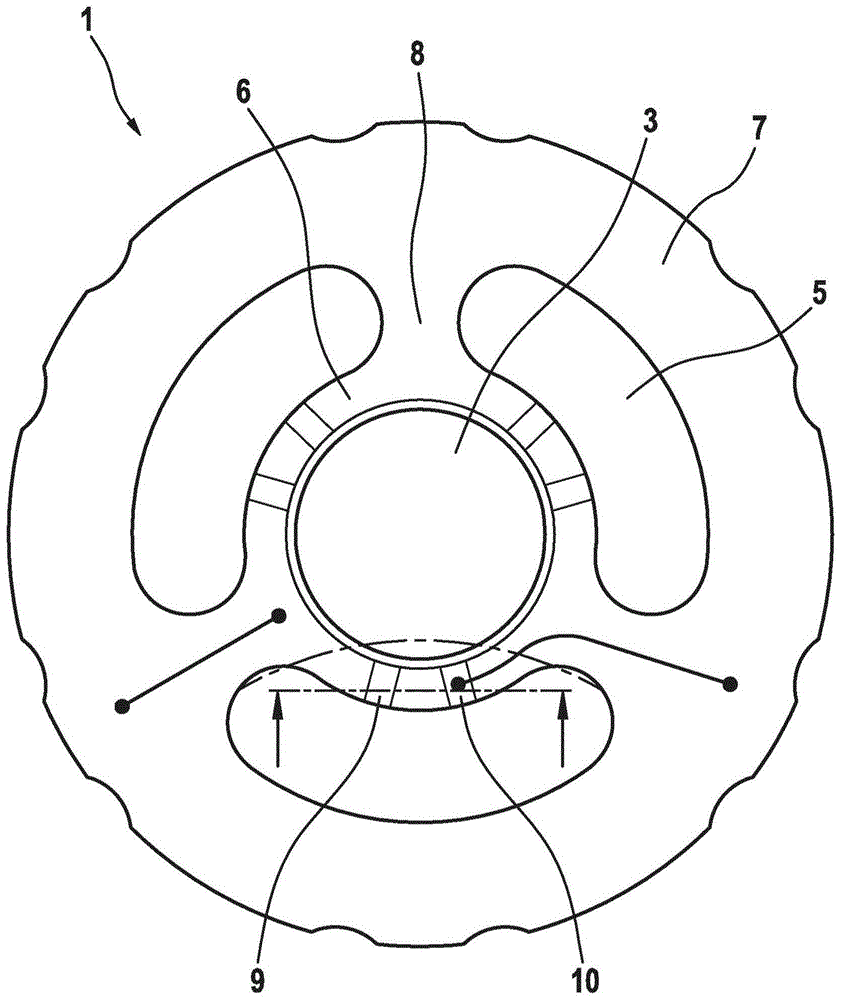

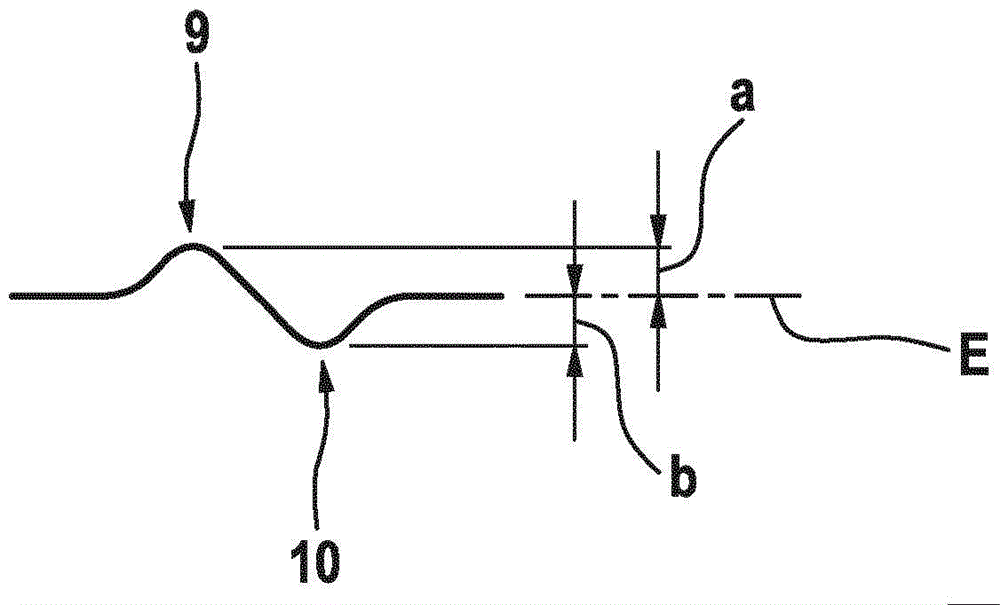

[0031] The sleeve-shaped plunger body 17 has a ring 20 on the inner circumference, on which the support part 18 is supported on the one hand and a spring seat 1 is supported on the other hand. The spring seat 1 has a central bore 3 for receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com