Dispensing method and device for dispensing

A slender, applicator technology, applied in the field of devices performing the method, capable of solving the problems of large second liquid, consumption, etc., and achieving the effect of easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

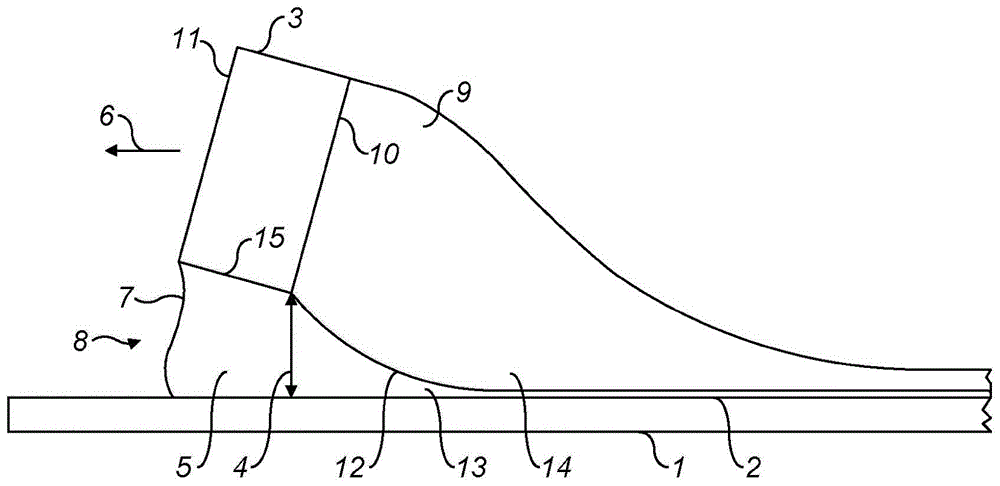

[0033] figure 1 An embodiment of a device for depositing a first liquid layer on a surface using the method according to the invention is shown in cross-section. Plate 1 , also shown in cross-section, has a surface 2 on which a first liquid layer is deposited. An applicator 3 in the form of a rod or slide is suspended above the surface 2 . The applicator and the surface form a gap 4 indicated by an arrow in the figure, which shows the minimum distance between the applicator and the surface. The applicator has a major axis perpendicular to the plane of the figure; the gap is elongated in the direction of the major axis. The gap is filled with elongated beads 5 of the first liquid.

[0034] In operation, slide 3 is moved over surface 2 in direction 6 . The water drop 5 has a front interface 7 with the gas 8 in front of the applicator 3 . Interface 7 extends from surface 2 to applicator 3 . A volume 9 of the second liquid having an elongated shape is only arranged on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com