Filter cartridge spacer tooth mold, filter cartridge spacer device and filter cartridge spacer method

A filter cartridge and fixed distance technology, applied in the coating and other directions, can solve the problems of artificially fixed folding distance of the filter material, the glue is not strong, and the process cost is increased, so as to save the glue time, stick firmly, and the process is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below:

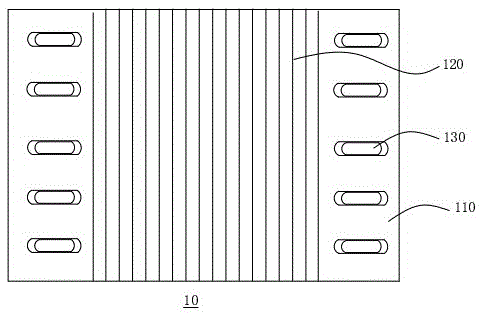

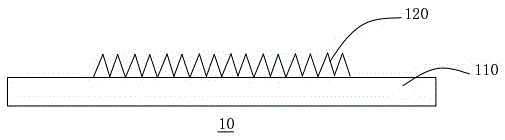

[0026] Such as figure 1 and figure 2 As shown, a filter cartridge fixed distance tooth mold 10 includes a body 110 and a tooth structure 120 arranged on the body 110. match the marks. The teeth of the tooth structure 120 cooperate with the creases of the filter material to fix the creases of the filter material and set the distance of the folds of the filter material.

[0027] The body 110 is further provided with a plurality of strip-shaped fixing grooves 130 , which are evenly distributed on the sides of the tooth-shaped structure 120 , and preferably, the plurality of strip-shaped fixing grooves 130 are arranged in parallel. During probation, change the fixed position of bar-shaped fixing groove 130, thereby change the fixed position of filter cartridge spacer tooth mold 10 on the fixed seat of filter cartridge distance device, make it can be compatible with the hot-melt generator of hot-melt d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com