Bogie frame and side beam thereof

A bogie and side beam technology, applied in the field of bogie design and manufacture, can solve problems such as unfavorable bogies, heavy bogies, and loud noises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

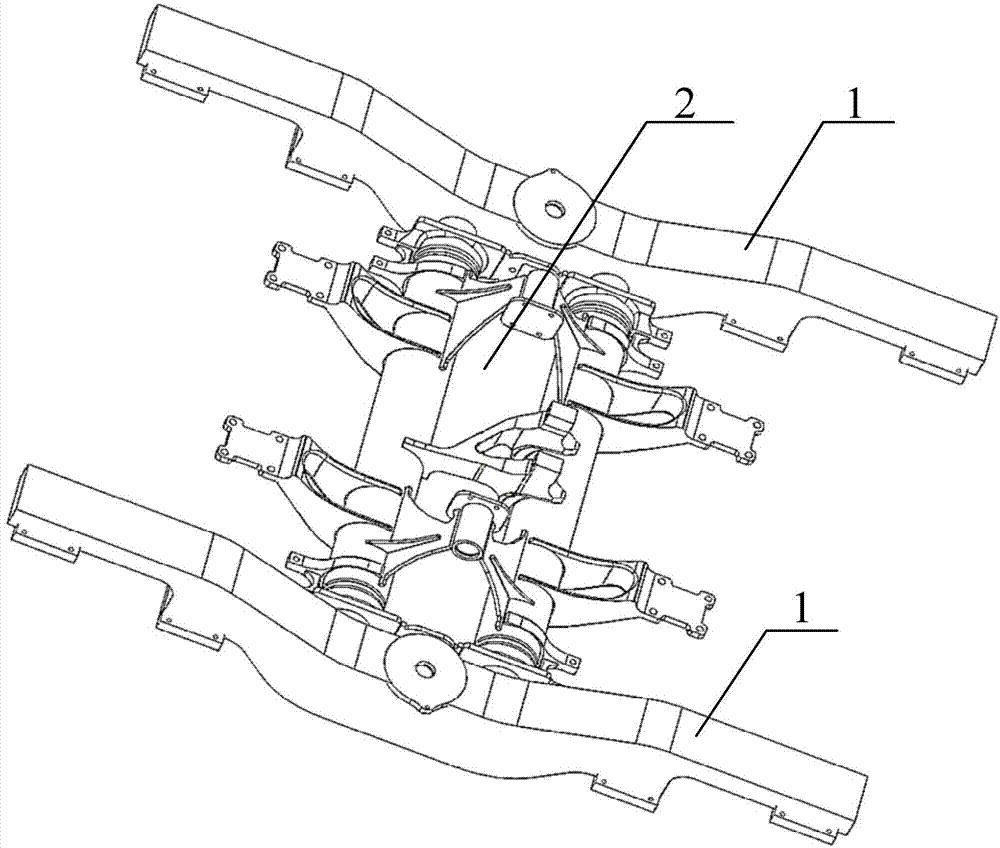

[0033] One of the purposes of the present invention is to provide a side beam of a bogie frame, so that after the bogie is formed, the overall weight of the bogie can be effectively reduced under the premise of ensuring the carrying capacity of the bogie, thereby meeting the requirements of high-speed rail vehicles on the bogie . Another object of the present invention is to provide a bogie frame with the above side beam.

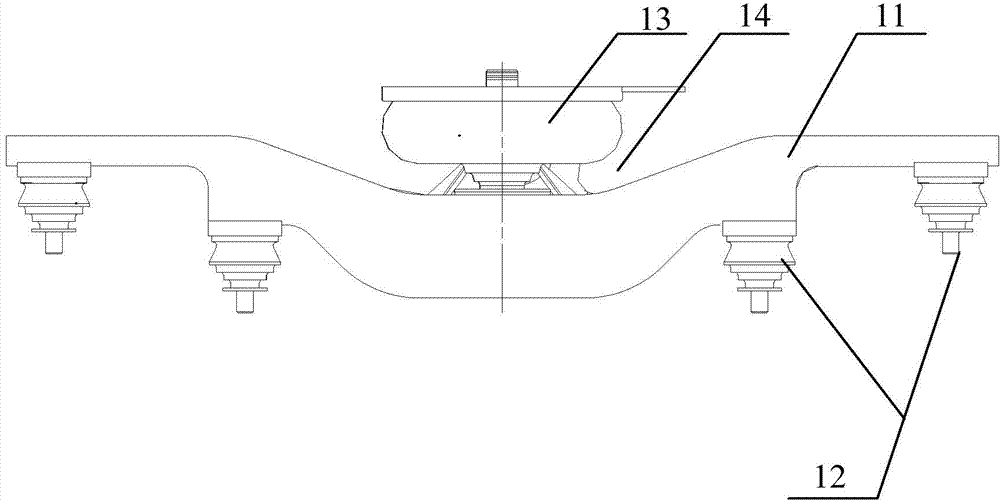

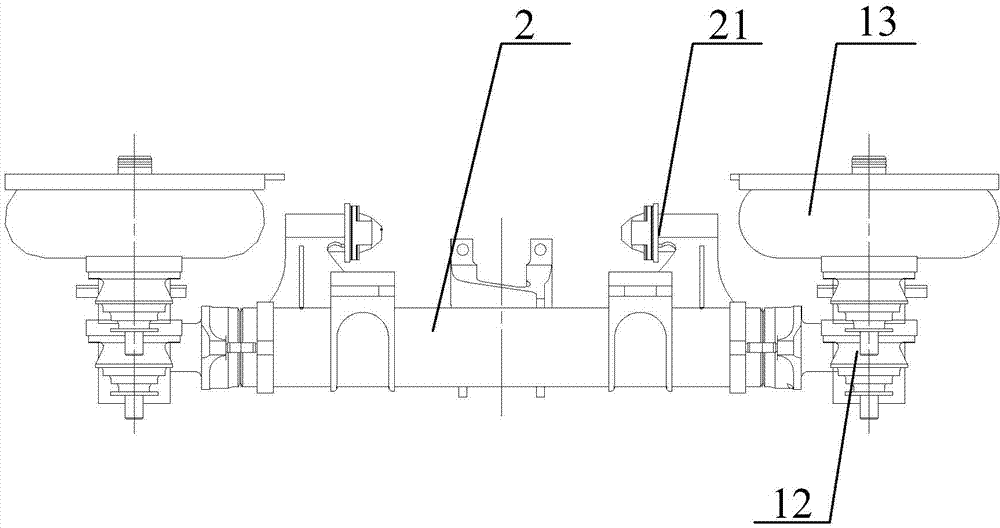

[0034] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The embodiment of the present invention discloses a side beam of a bogie frame. The side beam is used to form a bogie frame for a rail vehicle after being installed and matched with a metal crossbeam. Specifically, the side beam 1 includes a side beam body 11 and a The buffer parts on the side beam body ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap