Assembly type prestress honeycombed ribbed web plate composite beam

A technology of prestressed and composite beams, applied in the direction of long-strip structural components, structural elements, and building components used for load-bearing, can solve the problem of low shear bearing capacity and buckling resistance, affecting the overall function of the floor, and lack of effective Constraints and other issues to achieve excellent out-of-plane stiffness, improved shear bearing capacity, and improved out-of-plane deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawings and examples.

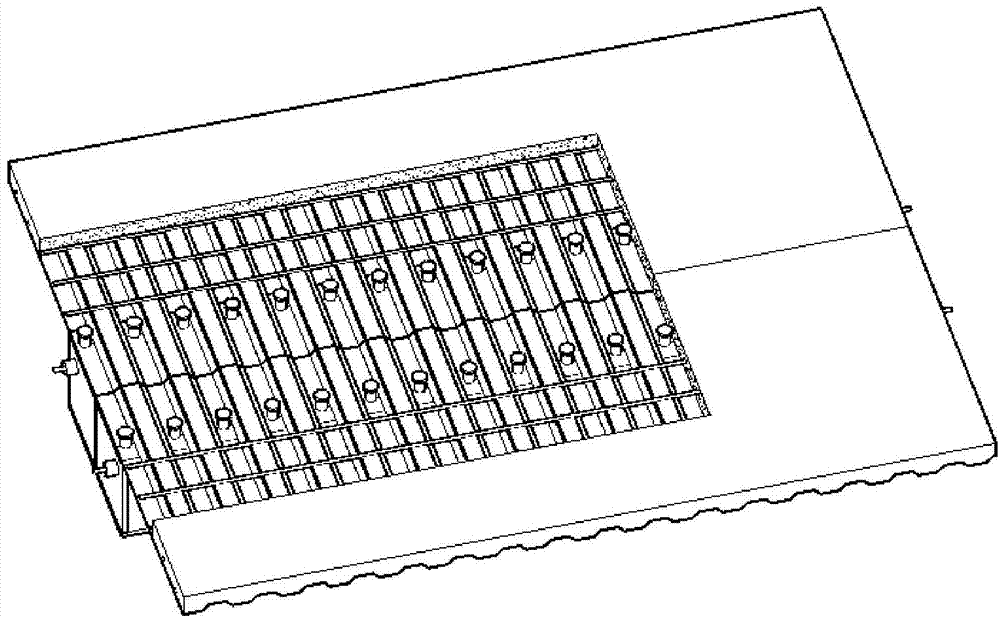

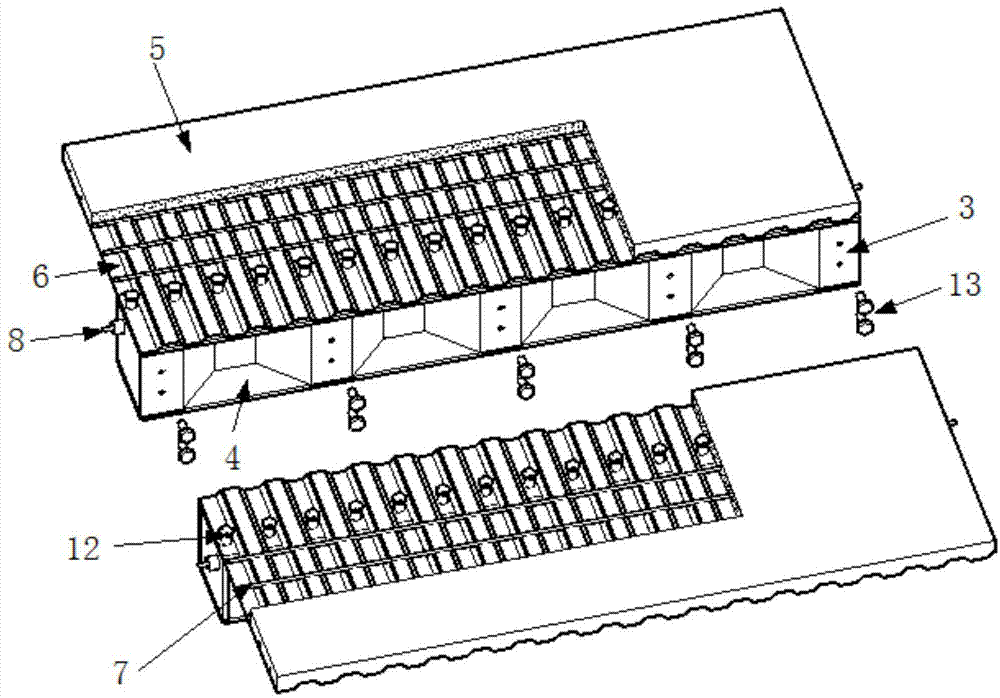

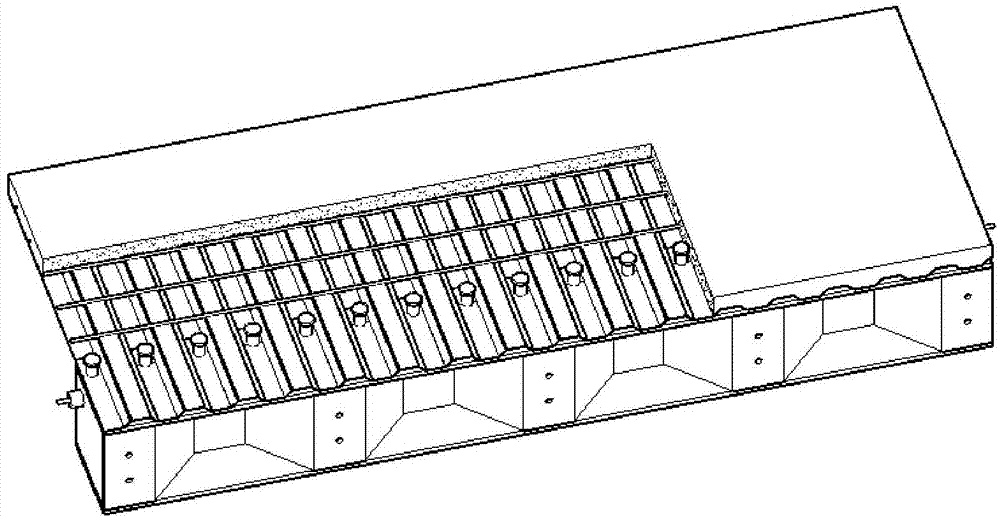

[0031] like figure 1 The schematic diagram of the fabricated prestressed honeycomb ribbed web composite beam is shown, figure 2 is the exploded view of the structural unit of the assembled prestressed honeycomb ribbed web composite beam, image 3 is a schematic diagram of a prestressed corrugated web ribbed channel steel composite beam, Figure 4 It is the unit exploded view of the prestressed corrugated web ribbed channel steel composite beam. An assembled prestressed honeycomb ribbed web composite beam is composed of two prestressed corrugated web ribbed channel steel composite beams 1 through bolts 13 Assembled, two prestressed corrugated webs and ribbed channel steel composite beam 1 webs are butted, and bolts 13 are used to assemble and connect at the corresponding holes at the webs to form a honeycomb web; prestressed honeycomb ribs Web channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com