Traction mechanism for drilling rig towed by drilling rig

A technology of rock drilling rig and traction mechanism, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of easy damage of tensioning rope, labor-intensive and labor-intensive etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

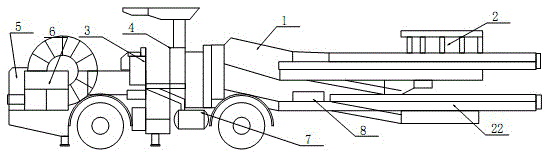

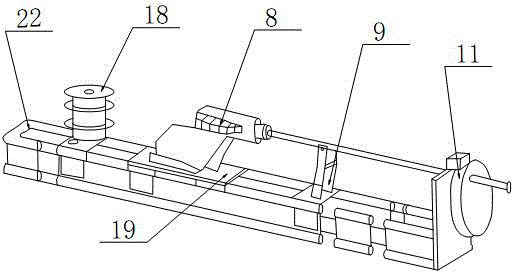

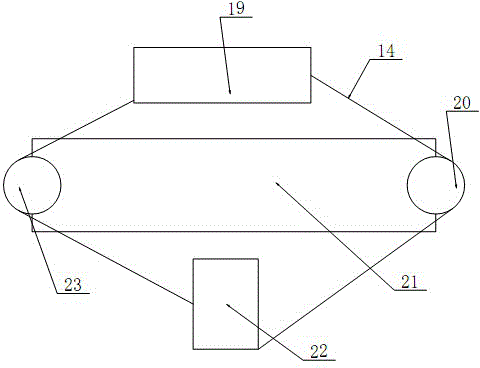

[0021] Embodiment 1: a kind of tension rope and using method for rock drilling jumbo thruster, see Figure 1-4 , the present invention includes a tension rope 14, a front pulley 23, a rear pulley 20, a drilling rig carriage 19 of a rock drilling jumbo and a propulsion beam 22 of the rock drilling jumbo, and the drilling rig carriage 19 is slidably installed on the rock drilling jumbo to propel On the slideway of the device, the front pulley 23 and the rear pulley 20 are respectively fixed on the front and rear ends of the cylinder barrel of the propulsion cylinder 21 in the propeller, and there are two tension ropes 14, which are respectively a traction rope and a return rope, wherein the traction One end of the rope is fixed on the drilling rig pallet 19, the other end is fixed on the propulsion beam 22 of the rock drilling rig around the front pulley 23, one end of the return rope is fixed on the drilling rig pallet 19, and the other end is wound around the rear The pulley 2...

Embodiment 2

[0033] Embodiment 2: the working principle of this embodiment is the same as embodiment 1, and the specific difference is that the tension adjustment mechanism includes a threaded button 15, an adjusting rope 24, an adjusting screw 26, a backing plate 27 and a U-shaped fixed pipe 25, and a threaded button 15 The two ends are respectively fastened and connected with the adjustment rope 24 and the tension rope 14, the bent end of the U-shaped fixed pipe 25 is fixed with the adjustment rope 24, and its open end is fixed in the backing plate 27, and the backing plate 27 is penetrated by the adjustment screw 26 And the advancing beam 22 is fixed on the advancing beam 22, and the length of the stud part of the adjusting screw 26 is not less than the sum of the thickness of the backing plate and the length of the screw hole.

[0034]When working, one end of the adjustment rope 24 is fixed with the tension rope through a threaded buckle, and after the other end is wound and fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com