Heating plate for MOCVD reaction chamber

A heating plate and reaction chamber technology, applied in the direction of ohmic resistance heating, electric heating device, gaseous chemical plating, etc., can solve the problems of hidden short circuit, uneven heating, unreasonable allocation of heating plate retention area, etc., to improve stability, The effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

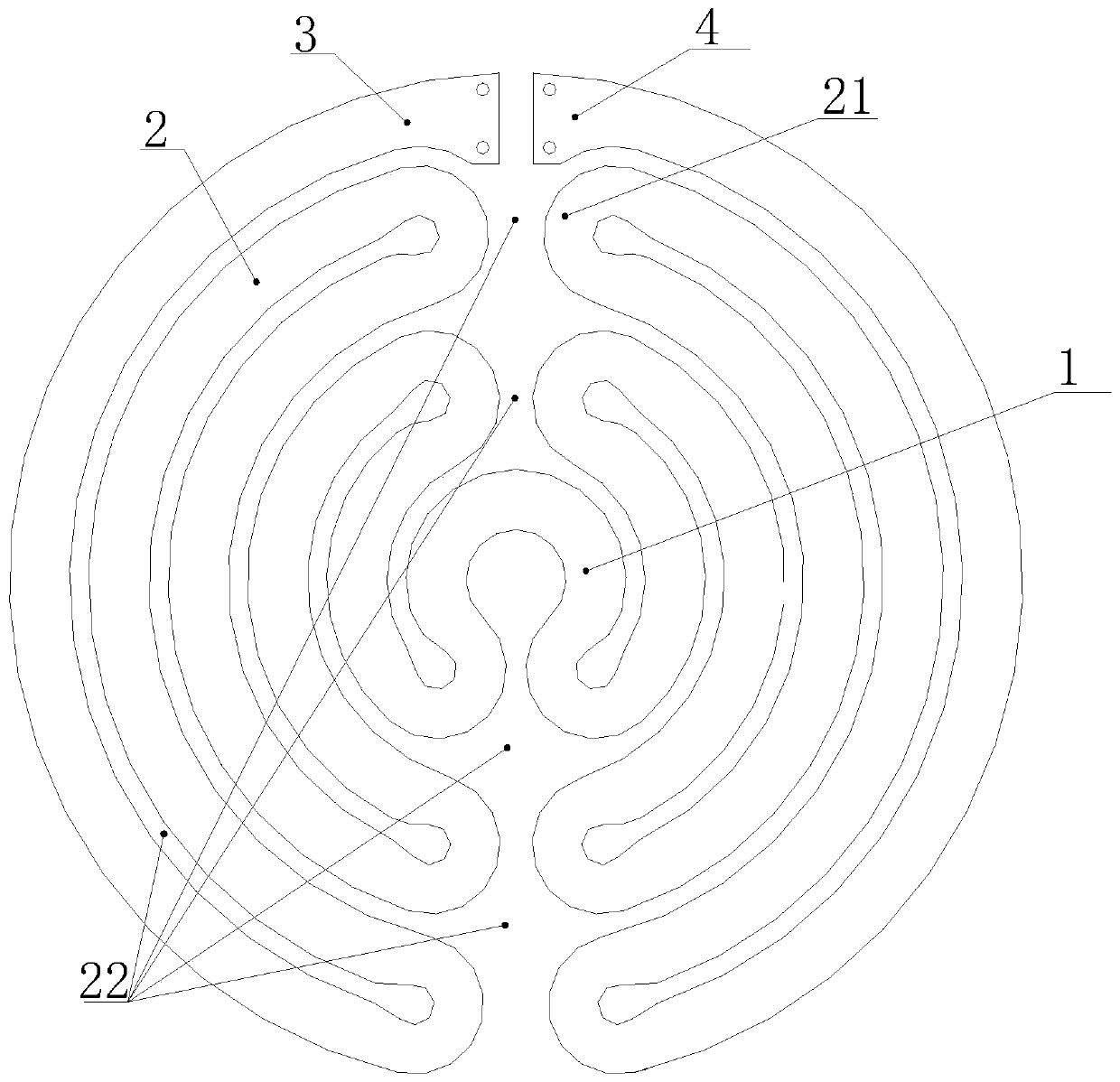

[0028] In order to solve the three technical problems in the prior art, the present invention provides a heating plate, which includes several sets of heating fins with an even number. In specific use, even groups of heating chips need to divide the heating chips into two groups, and each group is connected in parallel with two poles respectively connected to the power supply. Generally, the number of heating chips can also be set to 4 groups or 6 groups, etc. Although the more groups are, the easier it is to cause heating instability, but for a larger area that needs to be heated, multiple groups of heating chips can be used to extend the heating chip. lifespan.

[0029] All heating sheets are arranged symmetrically to the center; the shape of each group of heating sheets is arc-shaped and expands outward from the center point O; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com