Capacitive ignition device with speed limit and easy start functions

An ignition device, capacitive technology, applied in the direction of a capacitor energy storage device, etc., can solve problems such as difficulty in starting the engine, difficulty in starting at low speed, small change in the ignition angle of the igniter, etc. Solving startability problems, effect of ignition timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

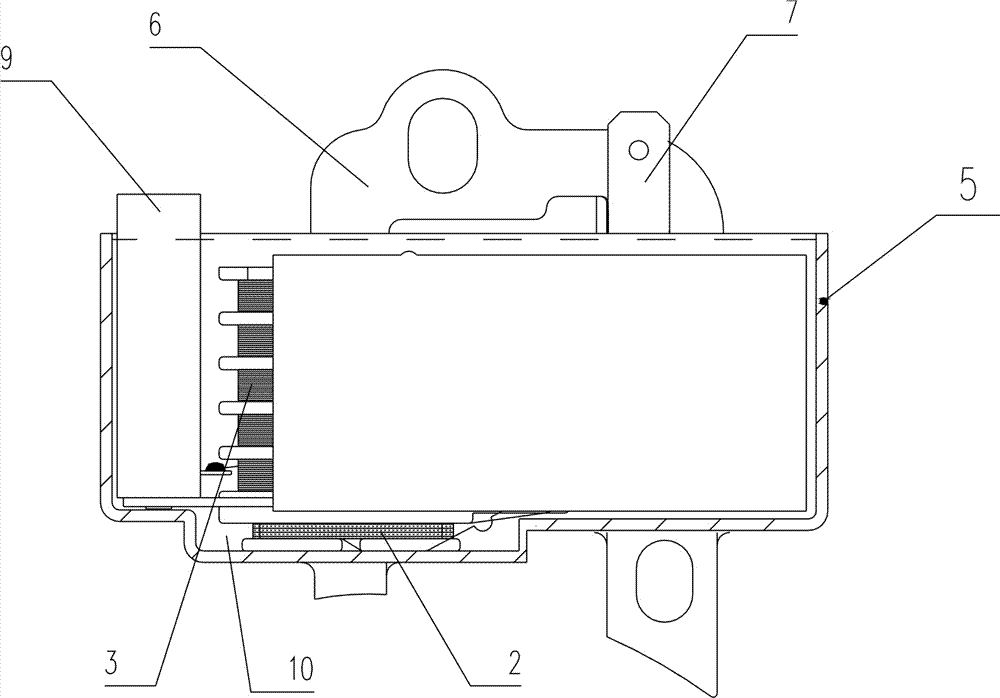

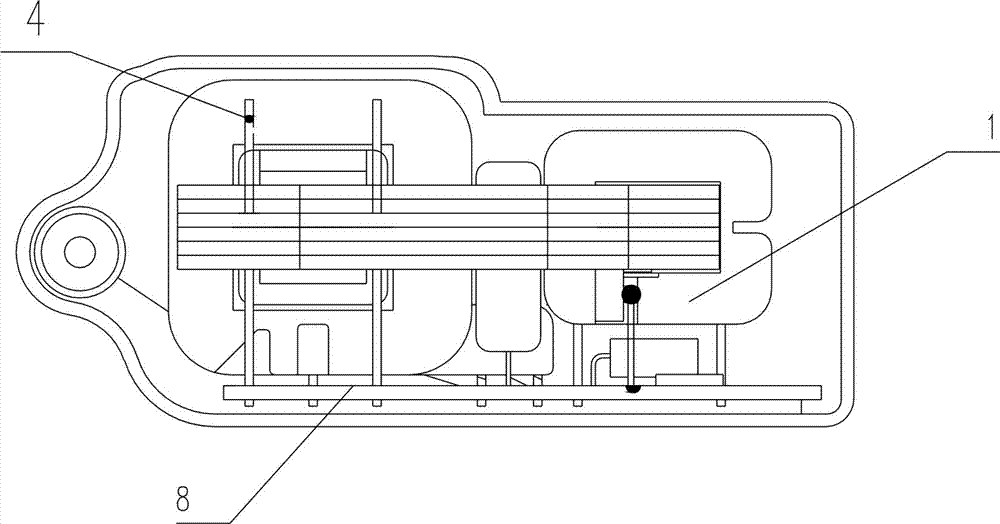

[0017] Such as figure 1 , 2 Shown is a schematic diagram of the external mechanical structure of the present invention, a capacitive ignition device with speed limiting and easy-to-start functions, including a charging coil 1, a trigger coil 2, a secondary coil 3, a primary coil 4, a casing 5, and an iron core 6 , flame extinguishing sheet 7, circuit board 8, terminal post 9 (high-voltage line lead-out) and epoxy resin 10 filled in the space in the shell 5.

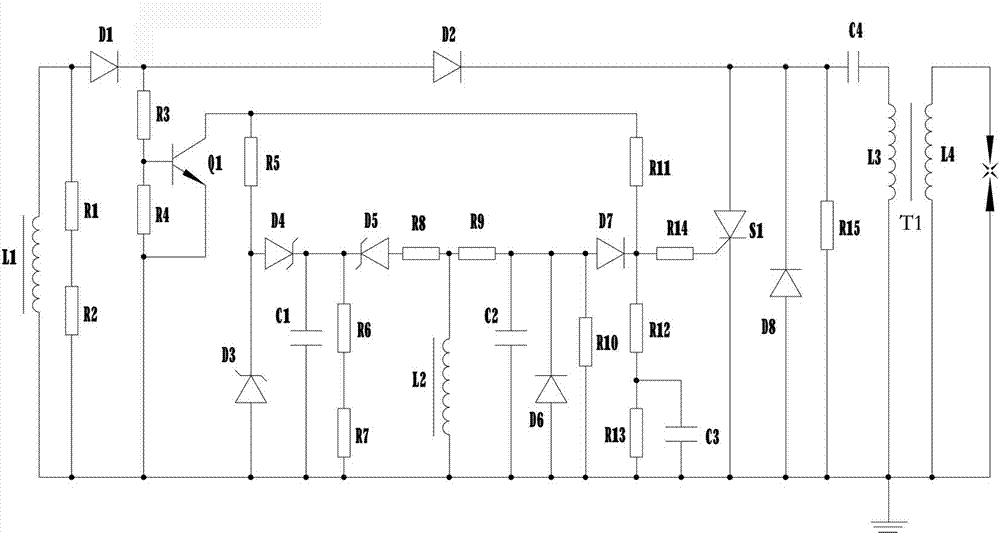

[0018] Such as image 3 As shown, a capacitive ignition device with speed-limiting and easy-start functions includes a charging circuit for charging the ignition capacitor, which includes a charging coil L1, diodes D1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com