Split type heat-pump water heater and water supply control method thereof

A technology of heat pump water heater and control method, which is applied in the direction of fluid heater, lighting and heating equipment, etc., which can solve the problems of inability to heat cold water, high failure rate, and failure of hoses, etc., to reduce floating balls and hoses, and reduce movement Parts, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The invention discloses a split-type heat pump water heater and a water supply control method of the split-type heat pump water heater. The technology is optimized by improving the structure of the water heater and the improvement of the control method.

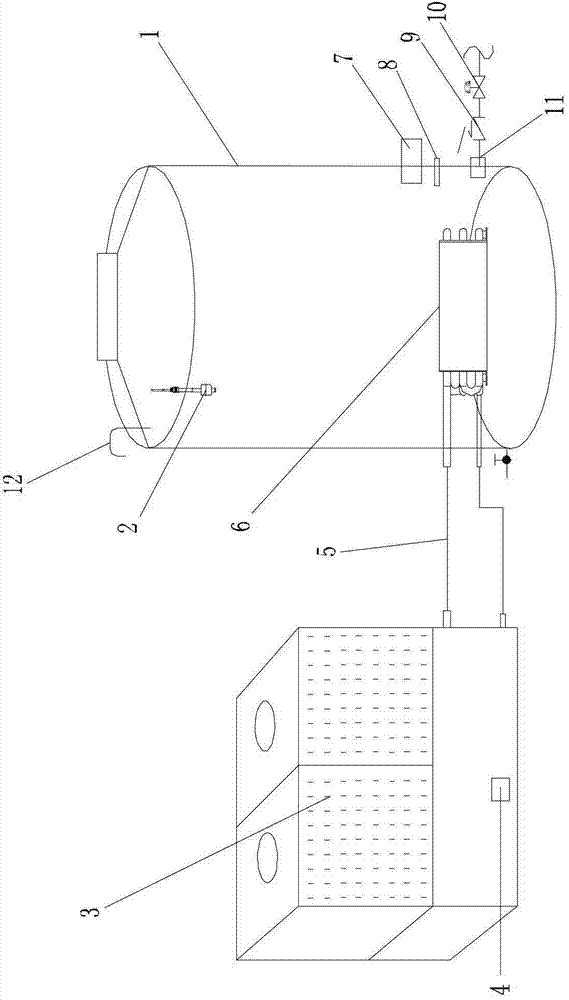

[0029] as attached figure 1 As shown, a split heat pump water heater includes a heat pump main unit 3 and a water tank 1. A condenser 6 is provided in the water tank 1. The heat pump main unit 3 is connected to the condenser 6 through a connecting pipe 5. The heat pump main unit 3 is provided with a controller 4. The bottom of the water tank 1 is provided with a cold water inlet 11, a temperature sensor 8 and a hot water outlet 7, the temperature sensor 8 is located above the cold water inlet 11, and the hot water outlet 7 is located above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com