Anti-freezing air door and air cooling refrigerator with same

An anti-freezing and damper technology, applied in household refrigeration devices, lighting and heating equipment, cooling fluid circulation devices, etc., can solve problems such as increasing power consumption and increasing material costs, saving material costs, avoiding freezing, reducing The effect of the risk of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

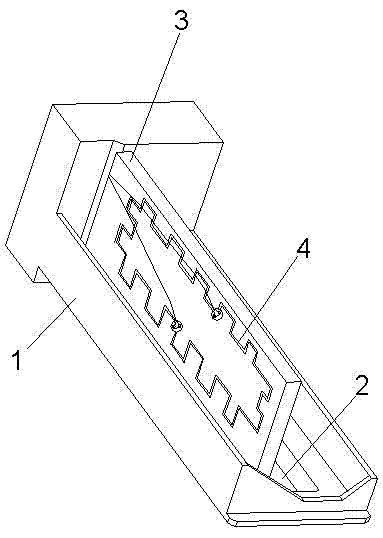

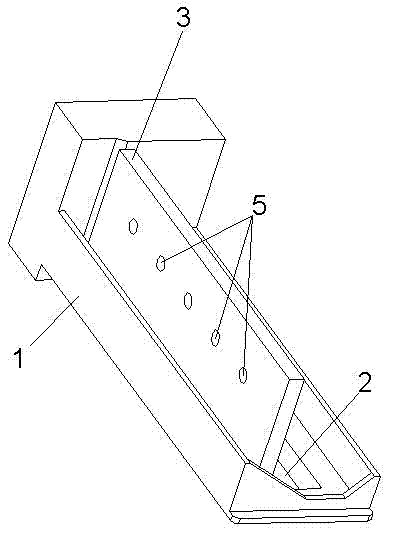

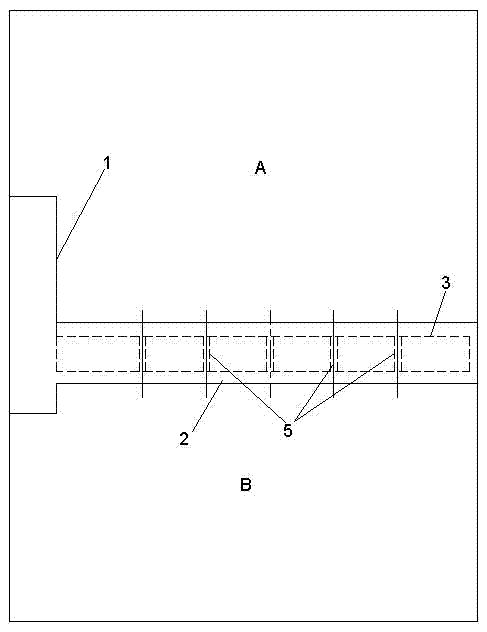

[0019] like figure 2 - image 3 As shown, the anti-freezing damper of the present invention includes a mounting frame 1 for being arranged in the air duct of an air-cooled refrigerator, the mounting frame 1 is equipped with an air duct opening 2 and a micro motor, the mounting frame 1 is provided with an air duct opening 2, and the mounting frame 1 A flap 3 is hinged, and the output shaft of the micro motor is connected with the flap 3 . The micromotor is a conventional part of the existing electric damper, and the figure does not show the micromotor. When the damper 3 is closed, the air duct opening 2 is closed, and when the damper 3 is rotated to open, the air duct opening 2 is opened, and the damper 3 is provided with a uniform temperature hole 5 . The temperature equalizing holes 5 are preferably uniformly provided with more than three holes on the damper 3, figure 2 Shown in is 5 uniform temperature holes 5 . The uniform temperature hole 5 is preferably circular.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com