Shelf device of vacuum freeze drier

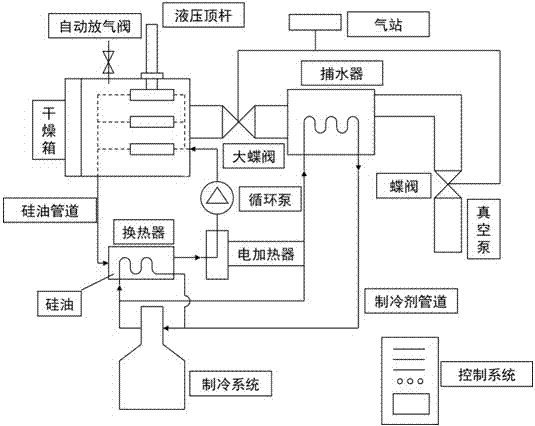

A vacuum freeze-drying and shelf technology, which is applied in the direction of dryers, drying chambers/containers, etc., can solve the problems of speeding up the freeze-drying speed, deformation of the full chassis, and affecting the heat transfer process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

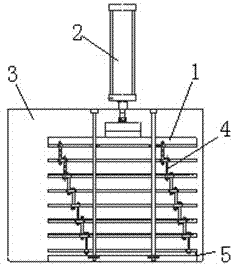

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] Such as image 3 As shown, the vacuum freeze dryer shelf device of the present invention includes a shelf 1, a hydraulic column 2, a drying box 3, and the like.

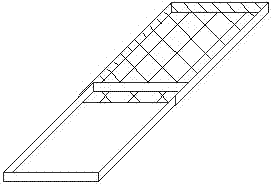

[0028] Several shelves 1 are arranged equidistantly from top to bottom, and are suspended in the drying box 2, the upper and lower shelves 1 are connected by hinges 4 located at both ends of the shelves 1, and the front of the bottom shelf 1 is connected by bolts 5 is connected with drying box 3 bottoms, and every layer of shelf 1 is welded with a side plate around. The height of the welded side plates around the shelf 1 is 15mm.

[0029] During the feeding before freeze-drying and during the freeze-drying process, the entire shelf device is in a suspended state, and the shelves are horizontal, so that the thickness of the liquid freeze-dried products is placed uniformly (generally ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com