Dynamic calibration device for small-size pressure sensor

A pressure sensor and sensor technology, used in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of low calibration efficiency, small range and low calibration accuracy, and achieve the effect of high calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

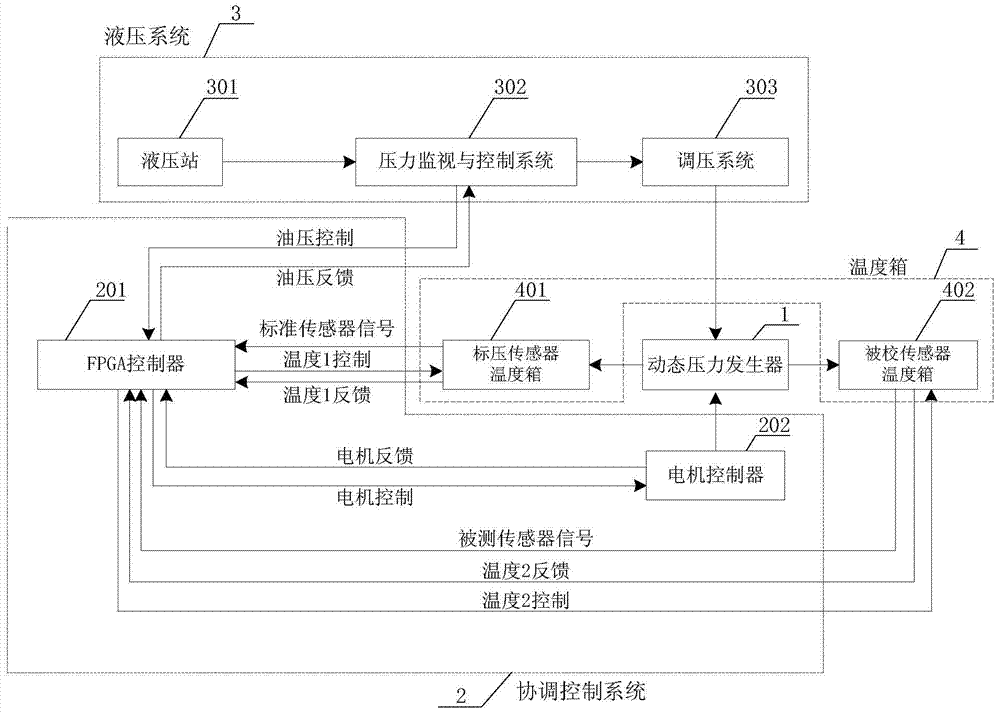

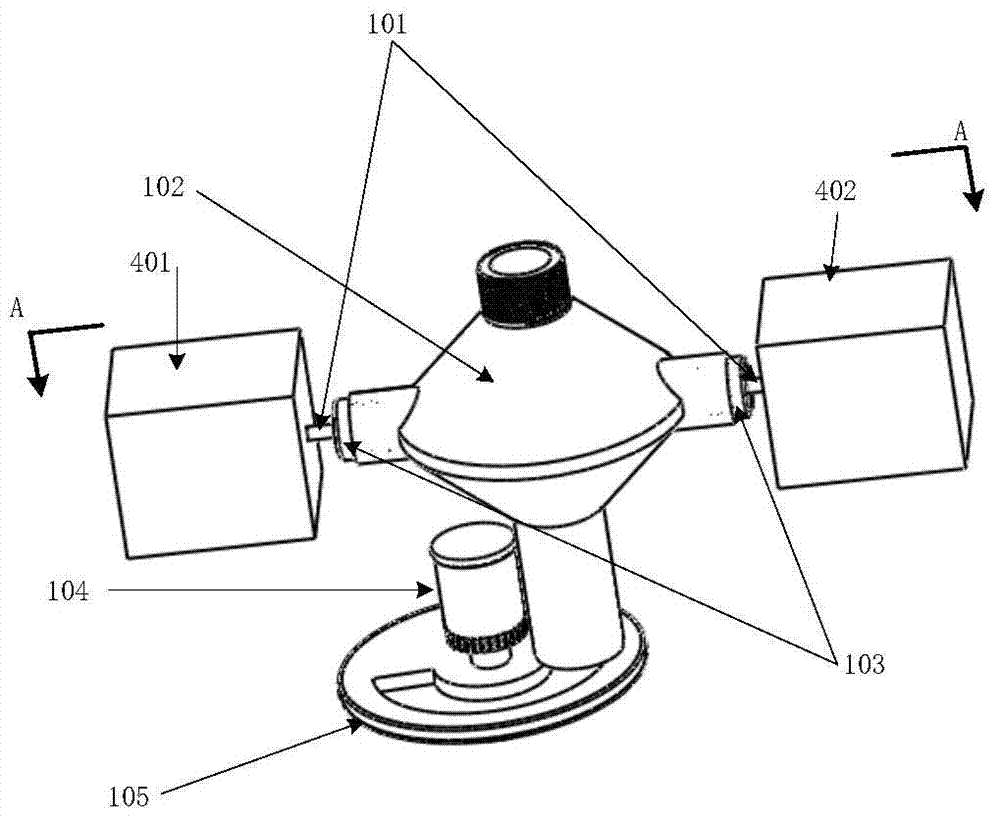

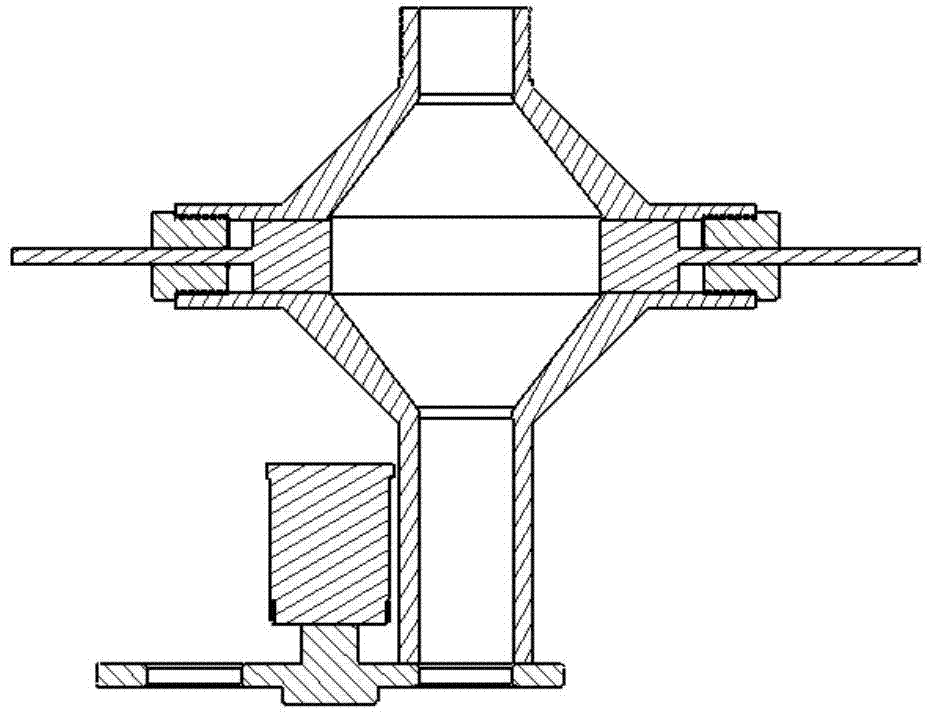

[0026] A dynamic calibration device for a small pressure sensor is composed of a dynamic pressure generator 1, a coordinated control system 2, a hydraulic system 3 and a temperature box 4. Such as figure 1 As shown, the hydraulic system 3 is responsible for providing the dynamic pressure generator 1 with the pressure oil set by the coordination control system 2, which is composed of a hydraulic station 301, a pressure monitoring and control system 302 and a pressure regulation system 303. The hydraulic station 301 supplies the oil source, the pressure monitoring and control system 302 is responsible for receiving the signal from the coordinated control system 2, and realizes the control and monitoring of the input pressure, and the pressure regulating system 303 realizes the fine adjustment of the output oil pressure of the hydraulic system 3, and supplies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com