Nondestructive detection method for micro-defects in thin ferromagnetic materials based on static magnetometry

A ferromagnetic material, non-destructive testing technology, applied in the direction of material magnetic variables, can solve the problem of small size limit detection, achieve the effect of high detection speed, strong magnetic field strength, and simple measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

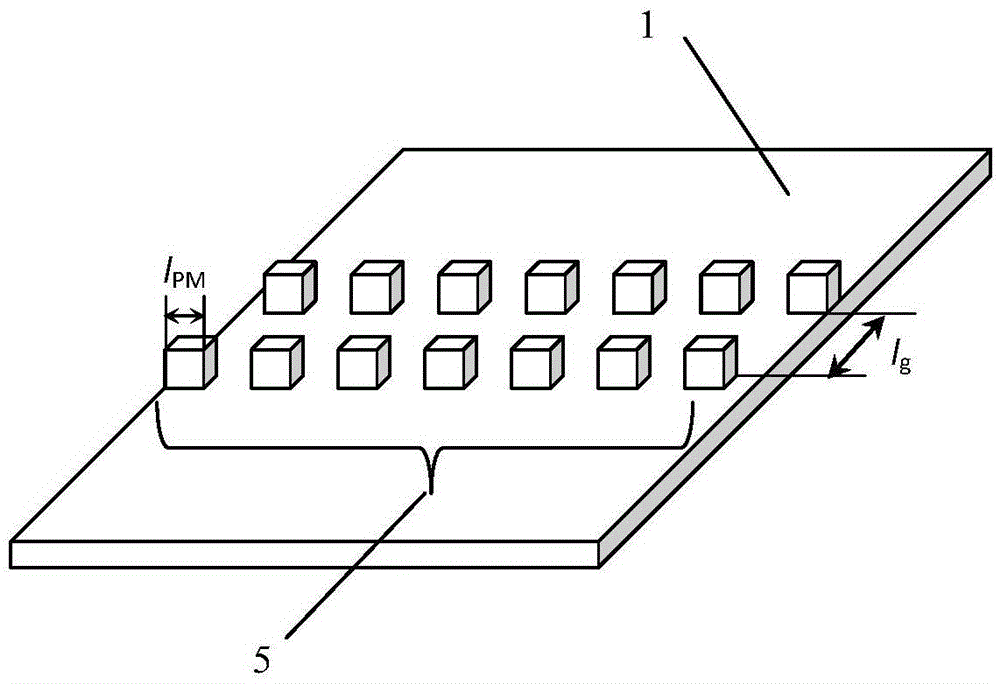

[0025] The non-destructive detection method for micro-defects in thin-plate ferromagnetic materials based on static magnetic force measurement proposed by the present invention comprises the following steps:

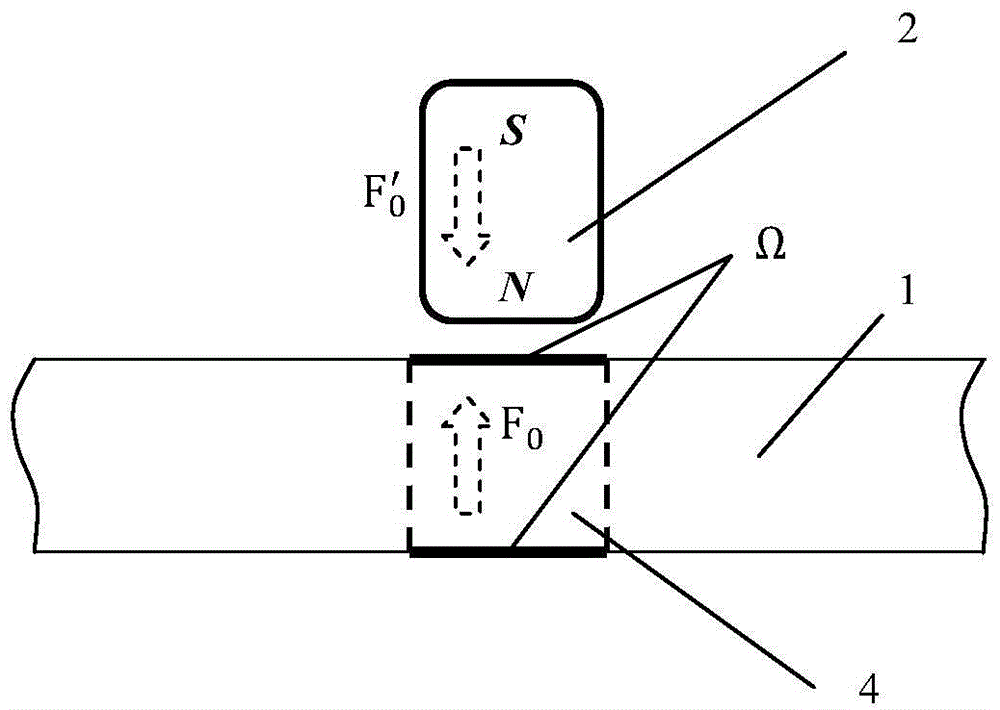

[0026] (1) Place the permanent magnet on the surface of the thin plate to be tested, and the magnetization direction of the permanent magnet is perpendicular to the surface of the thin plate;

[0027] (2) Calibrate with a calibration sheet of the same material as the sheet to be tested. The calibration method is: use a force sensor to measure the static magnetic force F acting on the permanent magnet 0 The reaction force F 0 ';

[0028] (3) Determination of internal defects of the thin plate to be tested, the determination process includes the following steps:

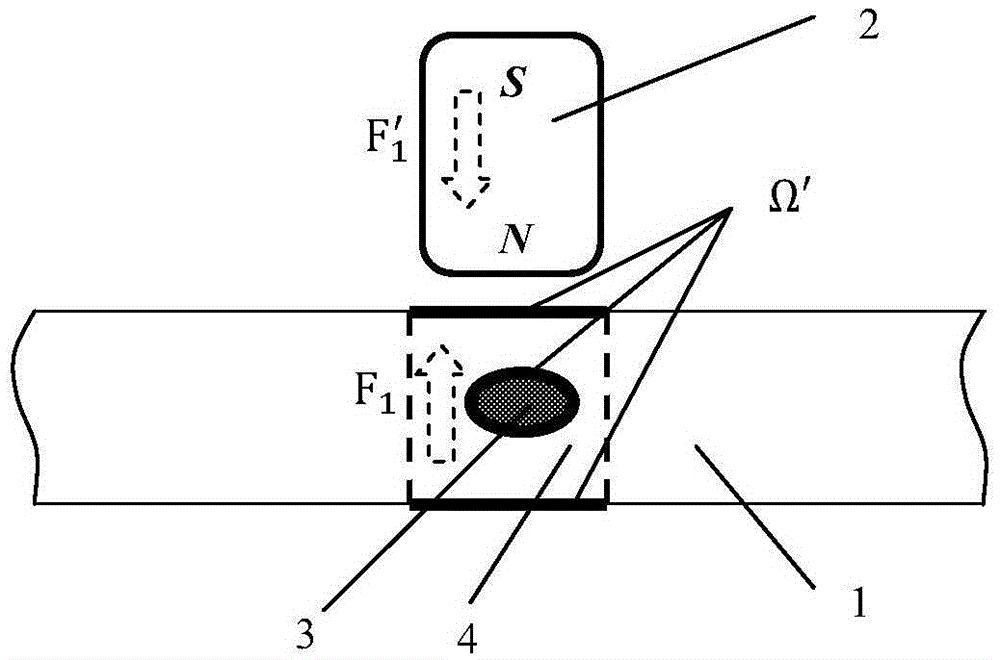

[0029] (3-1) Use a force sensor to measure the reaction force F on the permanent magnet 1 ';

[0030] (3-2) The above reaction force F 1 ' and F 0 ’ for comparison, if F 1 ' and F 0 ’ the same, it is dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com