Electric machine

An electrical and mechanical technology, applied in the direction of electrical components, electromechanical devices, DC commutators, etc., can solve the problems of acoustic damage, undesired, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

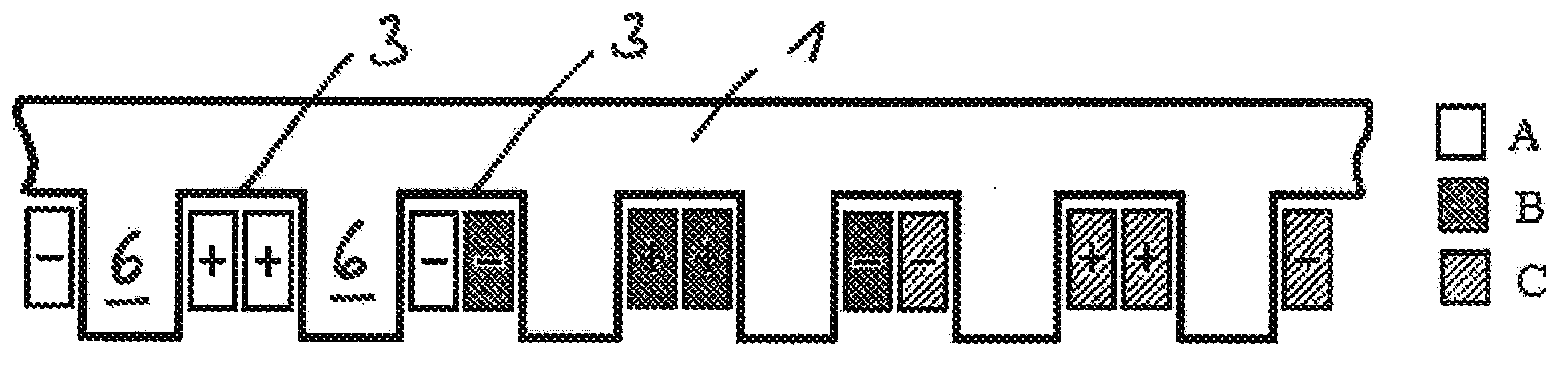

[0063] figure 1 The topology of the winding system with three phases A, B, C is shown. according to figure 1 The number of electrical phases of the electrical winding system totals three, thus corresponding to the electrical phase number 3 of the electrical system to which three strings of winding systems can be connected. The number of electrical phases is denoted by m.

[0064] The stator 1 with the installed winding system comprises six slots. The number of slots is represented by Z. For the purpose of simplifying the description, the stator 1 and the winding system installed therein are shown in an unrolled linear appearance, but could alternatively be realized as a rotating electrical machine comprising a stator of circular cross-section. In the case of a linear motor, the stator cross-section shown can be repeated periodically.

[0065] In addition, according to figure 1 The electrical windings of the are characterized in that they are concentrated windings in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com