Automatic welding device of rocker arm

An automatic welding and equipment technology, applied in the field of machinery, can solve the problems of not being able to fix the rocker arm or connecting rod, reduce production efficiency, and increase labor costs, so as to reduce labor costs and personal hazards, improve welding efficiency and welding quality, and realize The effect of automated welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

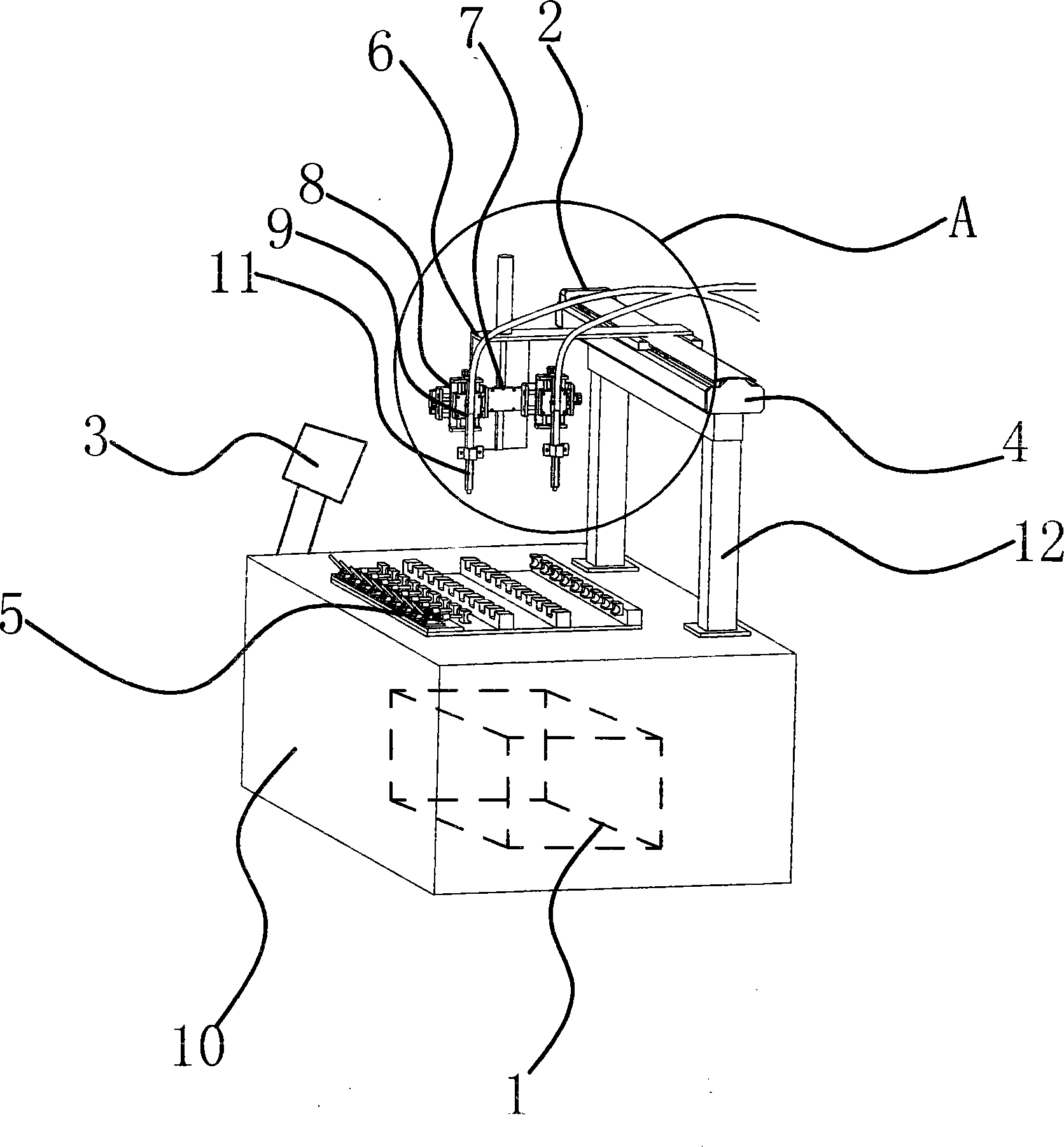

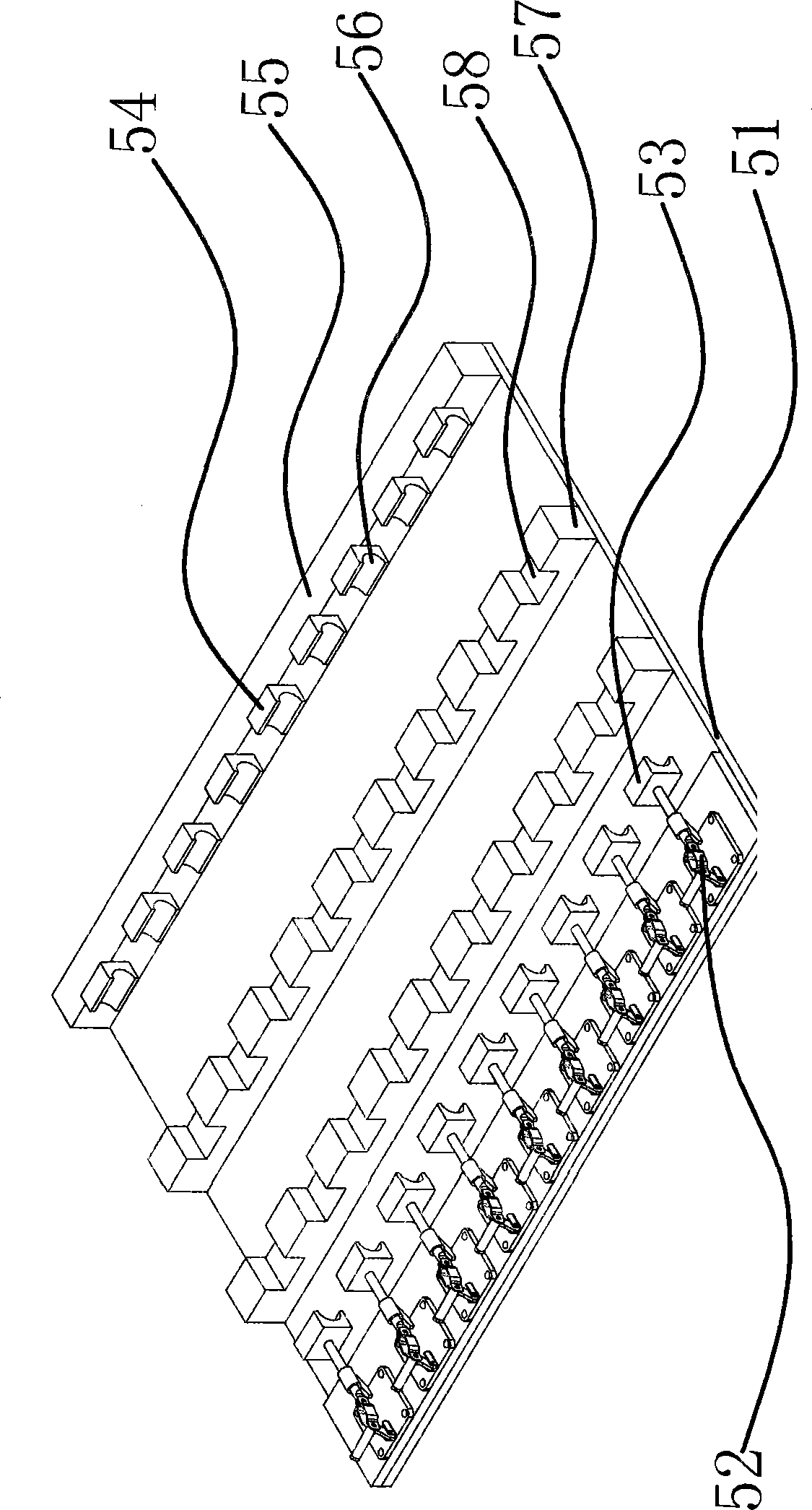

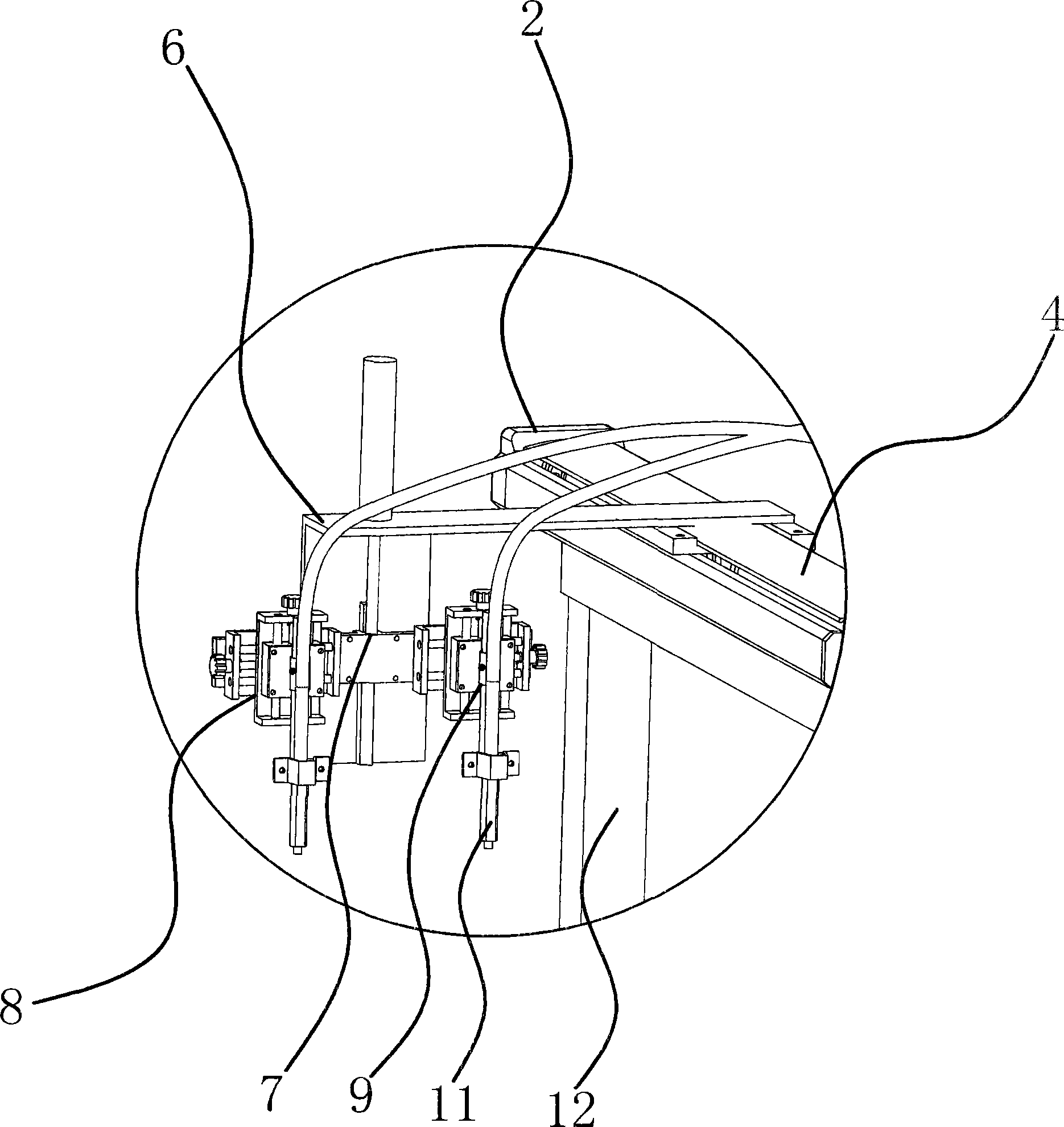

[0024] Such as figure 1 As shown, a rocker arm automatic welding equipment includes a workbench 10, a driver 1 is installed inside the workbench 10, a clamping device 5 is installed on the upper surface of the workbench 10, and a screw-type linear guide 4 passes through two columns 12 is installed on the workbench 10 on the side close to the fixing seat 55 of the clamping device 5, the driver 2 2 is an electric motor installed at one end of the screw-type linear guide 4, and one end of the L-shaped bracket 6 is connected with the screw-type linear guide 4 Movable connection, the other end is equipped with a lifter 7, which is located above the clamping device 5. The adjustment assembly 8 is installed on the lifter 7, and the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com