Method for manufacturing green environmental-protection solid wood multilayer plate

A kind of green environmental protection, production method technology, applied in the direction of wood veneer joining, manufacturing tools, wood processing utensils, etc., can solve problems such as deformation, cracking, waste of wood resources, etc. of wooden doors, and achieve the effect of enhancing anti-deformation

Inactive Publication Date: 2014-01-15

HEILONGJIANG HUAXIN FURNITURE

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the raw materials commonly used for solid wood decorative panels in the market are made of original wood and spliced panels, which not only wastes a lot of wood resources, but also often undergoes deformation, warping, cracking, etc. A series of problems have seriously affected the beauty and service life of wooden doors; thus, deformation, warping and cracking of wooden doors have become a major problem concerned by the entire society and the wooden door industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

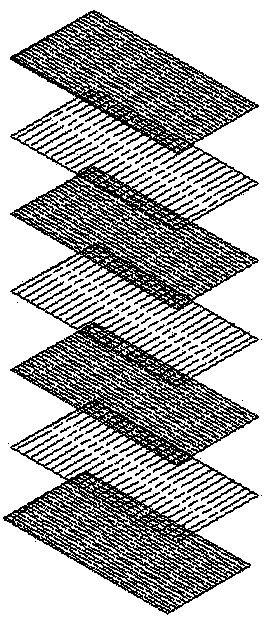

The invention discloses a method for manufacturing a green environmental-protection solid wood multilayer plate. The base material of the multilayer plate is a fire-resistant solid wood multilayer decorative board made of 100% solid wood veneers; according to the method, processes of classifying, drying, glue spreading, split jointing, repairing, still standing for quality maintenance, thickness determining, sanding and the others are adopted to realize the purposes of enhancing deformation resistance, warping resistance, cracking resistance and the like of the decorative board.

Description

technical field The invention relates to a production technology of a solid wood composite multi-layer decorative board, in particular to a manufacturing method of a green and environment-friendly solid wood multi-layer board. Background technique At present, the raw materials commonly used for solid wood decorative panels in the market are made of original wood and spliced panels, which not only wastes a lot of wood resources, but also often undergoes deformation, warping, cracking, etc. A series of problems have seriously affected the beauty and service life of wooden doors; thus, deformation, warping and cracking of wooden doors have become a major problem concerned by the entire society and the wooden door industry. Contents of the invention The object of the present invention is to provide a green environmental protection solid wood multi-layer board which is resistant to deformation, warping and cracking. In order to achieve the above object, the present inventi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B27D1/08B27M3/00

Inventor 刘淑兰

Owner HEILONGJIANG HUAXIN FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com