Decorative film, composite material object decorated by using decorative film, and manufacturing method of composite material object

A composite material and decorative film technology, applied in decorative art, special decorative structures, chemical instruments and methods, etc., can solve the problem of blocking communication electronic product antenna reception, appearance, monotonous color, and mechanical properties of carbon fiber-based composite materials that have not yet been seen Issues such as the manufacturing method of the molded object for antenna reception, etc., to achieve the effect of excellent mechanical properties and beautiful color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

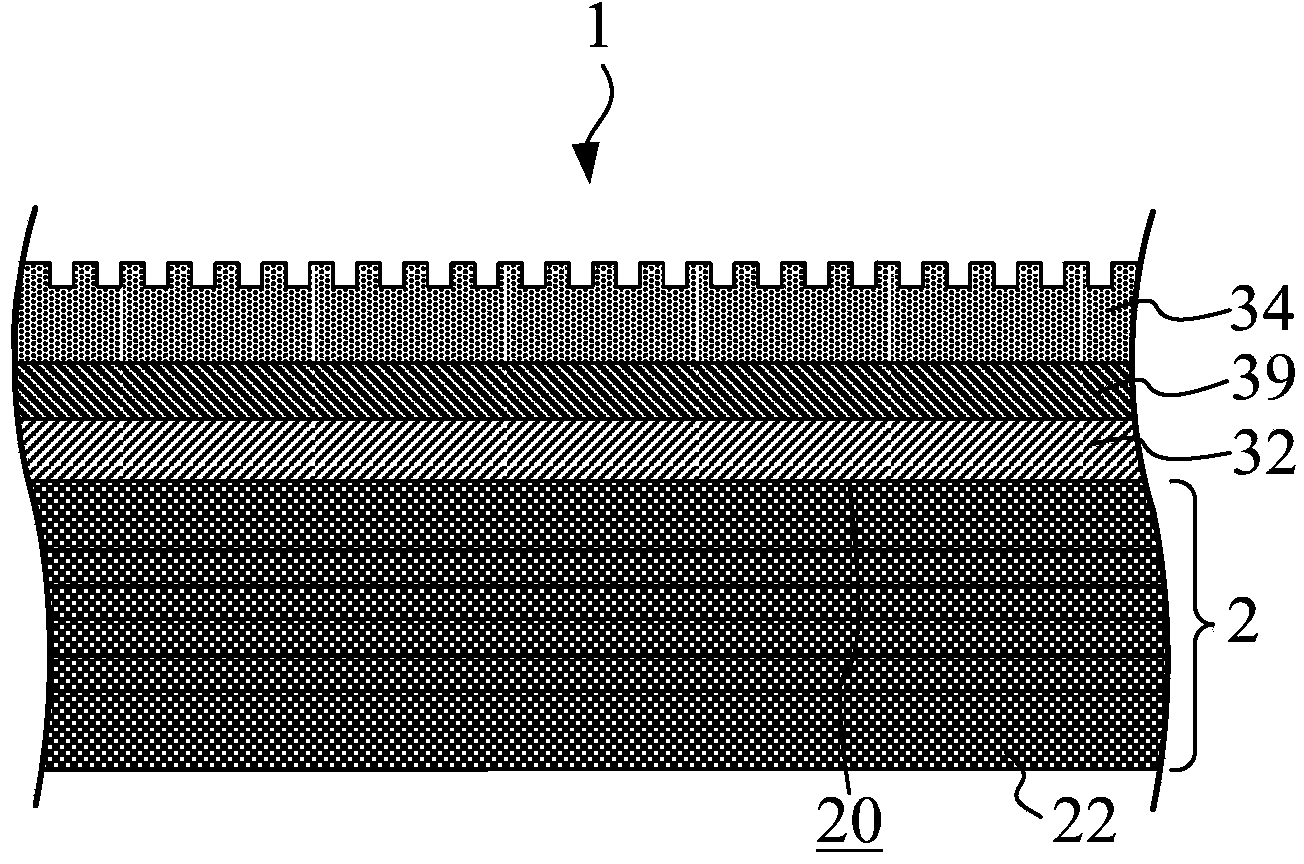

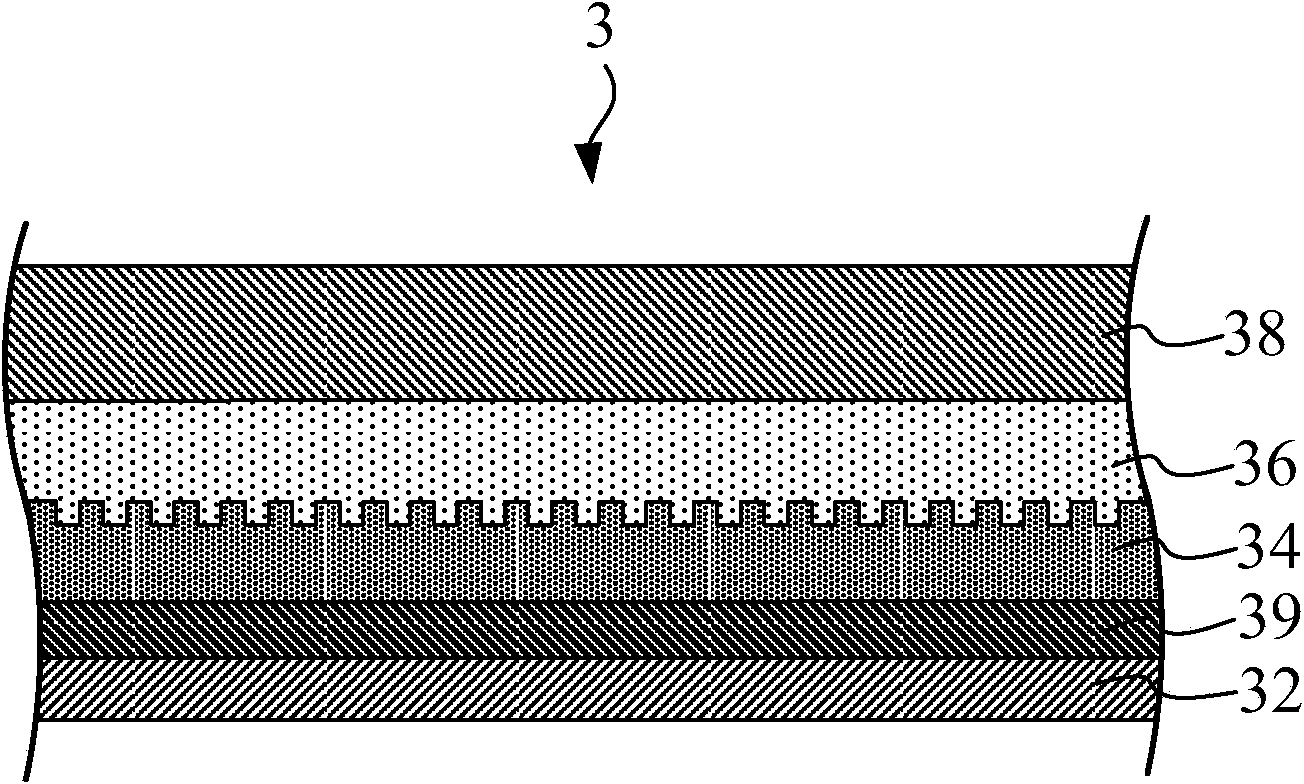

[0028] see figure 1 and figure 2 . figure 1 It is a partial cross-sectional view of a composite material object 1 according to a preferred embodiment of the present invention. figure 2 Partial cross-sectional view of the decorative film 3 employed for the composite material object 1 of the invention.

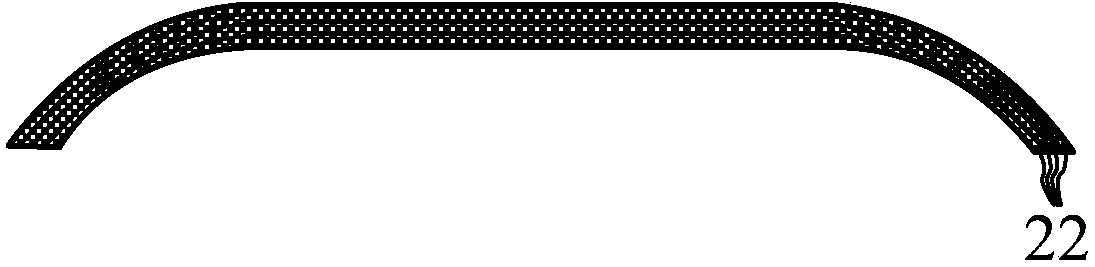

[0029] Such as figure 1 As shown, in this embodiment of the present invention, the composite material object 1 includes a main body 2 , an adhesive layer 32 and a textured layer 34 . The main body 2 is formed by stacking multiple layers of fiber materials 22 and has an outer surface 20 of the main body.

[0030] Such as figure 2 As shown, the decorative film 3 sequentially includes an adhesive layer 32 , a textured layer 34 , a release layer 36 and a base layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com