Novel hopper

A hopper, a new type of technology, applied in the field of new hoppers, can solve the problems of short service life, poor working reliability, poor hopper corrosion resistance, etc., and achieve the effects of pollution prevention, reliable connection and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

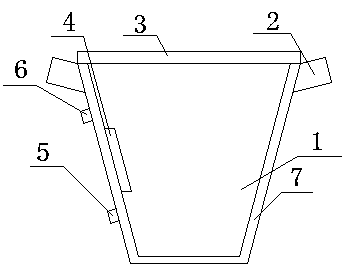

[0010] Such as figure 1 It is a schematic diagram of the structure of the present invention, a new type of hopper, including a bucket body 1, a material inlet 2, a sealing cover 3, a thermometer 4, a temperature sensor 5, a warning light 6 and an anti-corrosion layer 7, and two sides of the upper end of the bucket body 1 are provided. The feed opening 2, the bucket body 1 is provided with a sealing cover 3, the inner wall of the bucket body 1 is provided with a thermometer 4, the outer wall of the bucket body 1 is provided with a temperature sensor 5 and a warning light 6, the temperature sensor 5, the thermometer 4 and the warning light 6 Electrically connected, the inner wall of the bucket body 1 is covered with an anti-corrosion layer 7.

[0011] When in use, there is a material inlet 2 on both sides of the upper end of the bucket body 1, and a sealing cover 3 is provided on the bucket body 1 to prevent the material from being polluted by external impurities. A temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com